Tunnel secondary lining arch frame unit, arch frame structure constituted by same and erection method of arch frame structure

A secondary lining and arching technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of increasing the risk during tunnel operation, reducing the life of the secondary lining, and reducing the waterproof ability, etc., to achieve good application prospects and promotion value, high work efficiency, and the effect of preventing the rollover of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

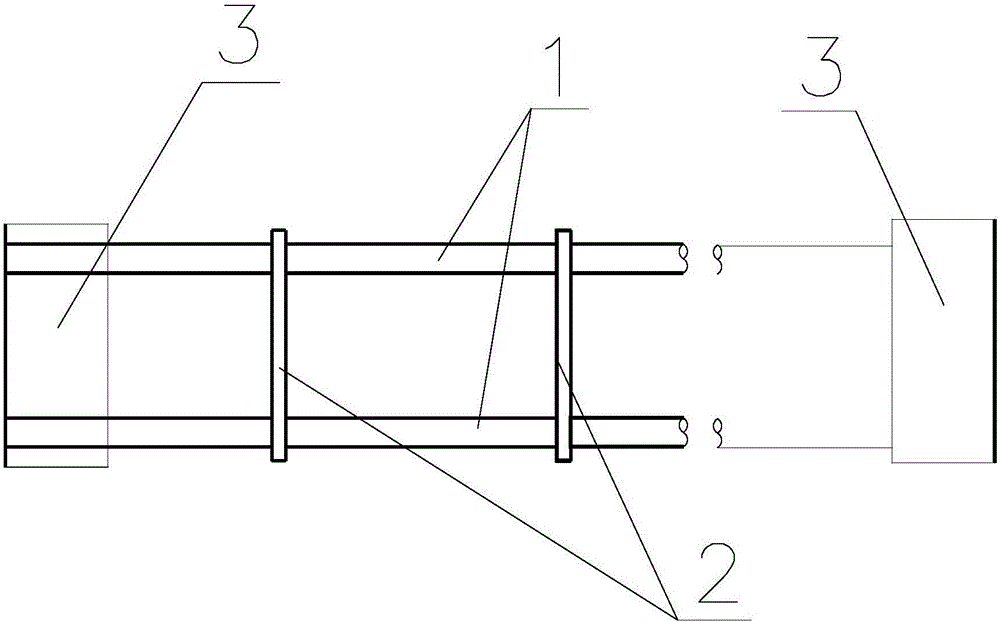

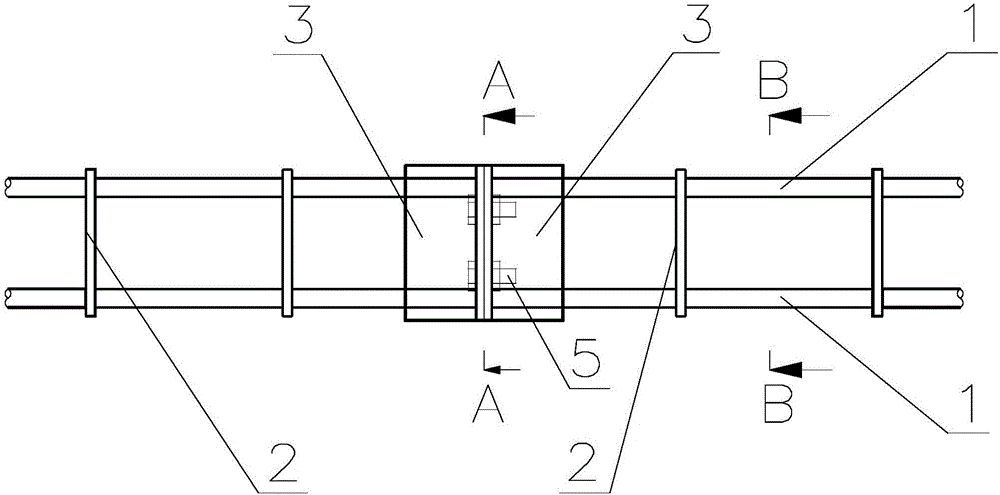

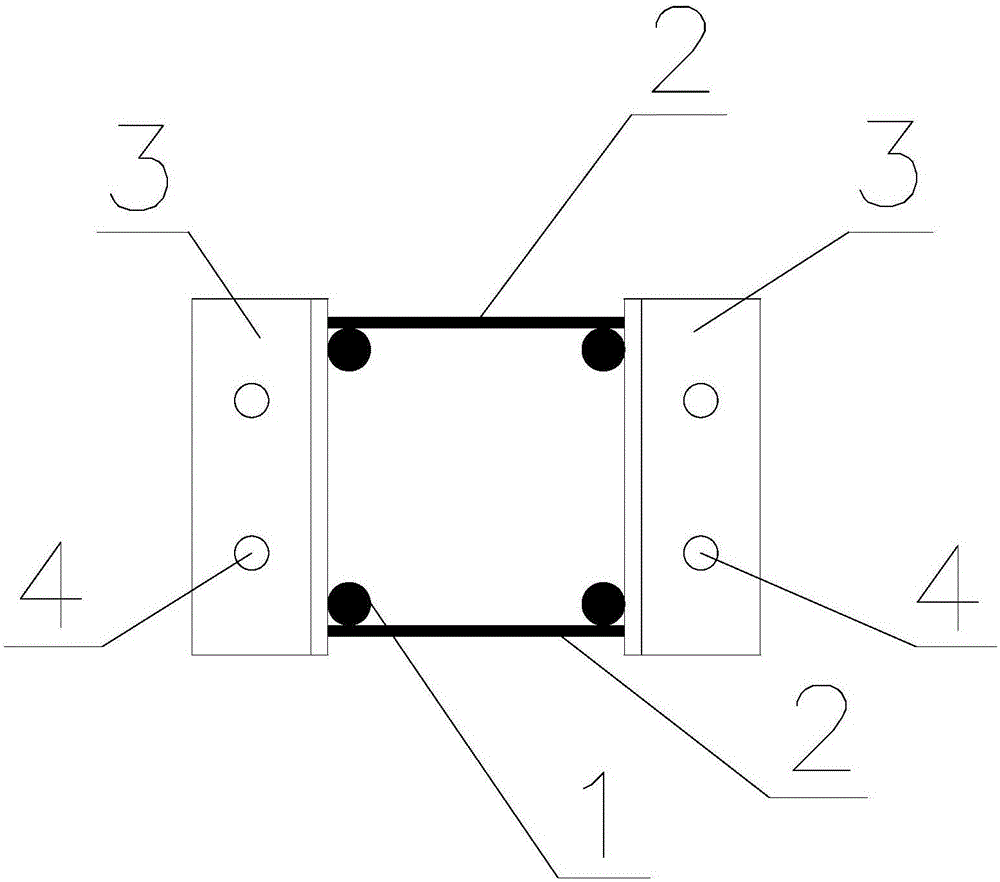

[0036] Such as Figure 1 to Figure 4 As shown, a tunnel secondary lining arch unit includes three arch unit main reinforcements 1 of the same length, and the three arch unit main reinforcements 1 together form an arch unit frame with an equilateral triangle cross section. The main reinforcement 1 of the arch unit is made of HRB335 or HRB400 steel, and the diameter of the main reinforcement 1 of the arch unit is 20mm-28mm. The exterior of all arch unit frames is fixedly connected by several stirrups 2 to form an arch unit skeleton, and the two ends of the arch unit skeleton are respectively fixedly connected with connecting angle steel 3, and bolt holes 4 are opened on the connecting angle steel 3. In this embodiment, The connecting angle steel 3 is made of Q235 steel material. Such as figure 1 , figure 2 As shown, the stirrups 2 are arranged at regular intervals along the length direction outside the arch unit frame; the stirrups 2 are made of HRB335 steel bar material or HR...

Embodiment 2

[0048] Such as Figure 1 to Figure 4 As shown, a tunnel secondary lining arch unit includes four arch unit main reinforcements 1 of the same length, and the four arch unit main reinforcements 1 together form an arch unit frame with a square cross-section, and two adjacent arch units The net spacing of the main reinforcement 1 of the unit is 350mm. The exterior of all the arch unit frames are fixedly connected by a number of stirrups 2 to form an arch unit skeleton, and the two ends of the arch unit skeleton are respectively fixedly connected with connecting angle steel 3 , and bolt holes 4 are opened on the connecting angle steel 3 .

[0049] Such as figure 1 , figure 2 As shown, the stirrups 2 are arranged at regular intervals along the length direction outside the frame of the arch unit.

[0050] Such as image 3 As shown, two bolt holes 4 are opened on the connecting angle steel 3, and bolts and nuts 5 are installed in the bolt holes 4; the connecting angle steel 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com