Engine knock detection method and engine pre-ignition detection method

A detection method and engine technology, applied in the directions of engine ignition, engine components, machines/engines, etc., to achieve the effects of perfect knock detection function, suppression of misjudgment, and improvement of knock detection threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

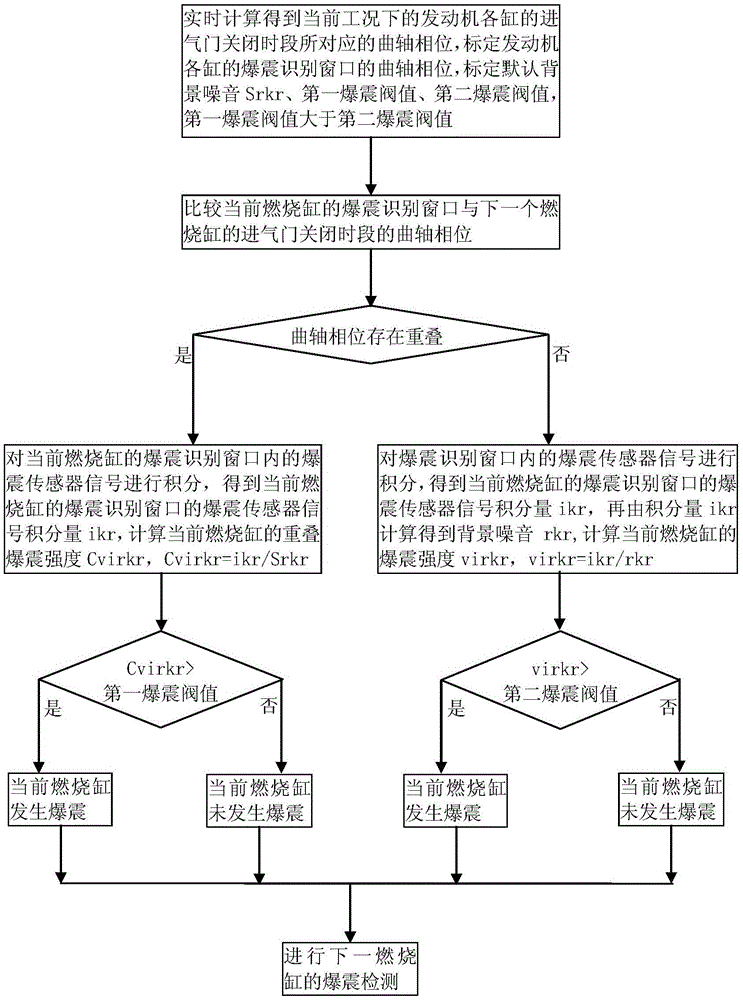

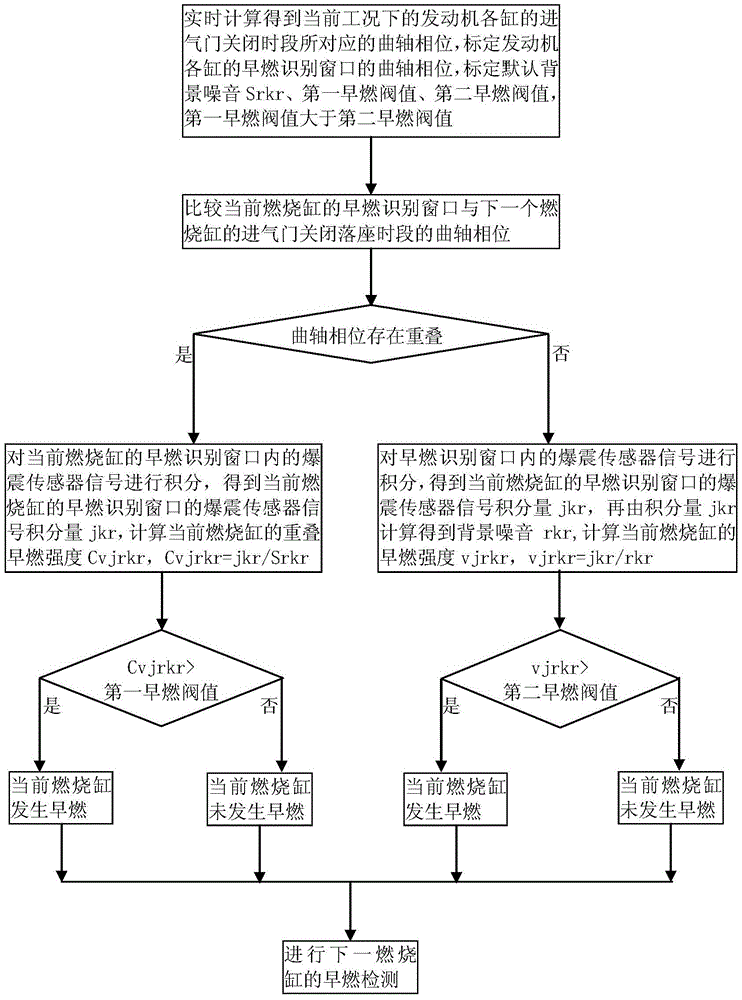

[0049] engine knock detection methods such as figure 1 shown, including the following steps:

[0050] 1. Calculate the crankshaft phase corresponding to the intake valve closing period of each cylinder of the engine under the current working condition in real time, calibrate the crankshaft phase of the knock recognition window of each cylinder of the engine, and calibrate the default background noise Srkr and the first knock threshold , the second knocking threshold, the first knocking threshold is greater than the second knocking threshold;

[0051] 2. Comparing the knock recognition window of the current combustion cylinder with the crankshaft phase of the intake valve closing period of the next combustion cylinder;

[0052] 3. If the intake valve closing period of the next combustion cylinder overlaps with the crankshaft phase of the knock identification window of the current combustion cylinder, it is judged that the intake valve closing noise enters the knock identificat...

Embodiment 2

[0061] Based on the engine knock detection method of Embodiment 1, in step 2, compare the knock recognition window of the current combustion cylinder with the crankshaft phase of the intake valve closing period of the next combustion cylinder; and compare the current ignition cycle with the previous ignition cycle , the change rate of the crankshaft phase during the intake valve closing period of the next combustion cylinder;

[0062] In step 3, if the intake valve closing period of the next combustion cylinder overlaps with the crankshaft phase of the knock identification window of the current combustion cylinder, and the change rate of the crankshaft phase of the intake valve closing period of the next combustion cylinder is greater than the set limit value, it is judged that the intake valve closing noise enters the knock identification window of the current combustion cylinder, and proceed to step 4; if the intake valve closing period of the next combustion cylinder is the ...

Embodiment 3

[0063] The engine knock detection method of the third embodiment optimizes the knock identification, and further judges the next combustion cylinder when the intake valve closing period of the next combustion cylinder overlaps with the crankshaft phase of the knock identification window of the current combustion cylinder. Whether the rate of change of the crankshaft phase during the closing period of the intake valve is fast enough, if the rate of change is high, a higher knock threshold is used for knock identification, and if the rate of change is low, a lower knock threshold is used for knock identification.

[0064] Embodiment three

[0065] Based on the engine knock detection method of Embodiment 1, in step 1, the first angle and the second angle are also calibrated, and the first angle is smaller than the second angle;

[0066] In step five, if it is detected that knocking occurs in the current combustion cylinder, the ignition angle of the current combustion cylinder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com