Engine Knock Detection Method and Engine Preignition Detection Method

A detection method and engine technology, applied in the direction of engine components, machines/engines, measuring devices, etc., can solve problems such as poor power, inability to eliminate noise interference with band-pass filter function, cut off fuel, etc., to improve the knock detection threshold, The knock detection function is perfect and the effect of suppressing misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

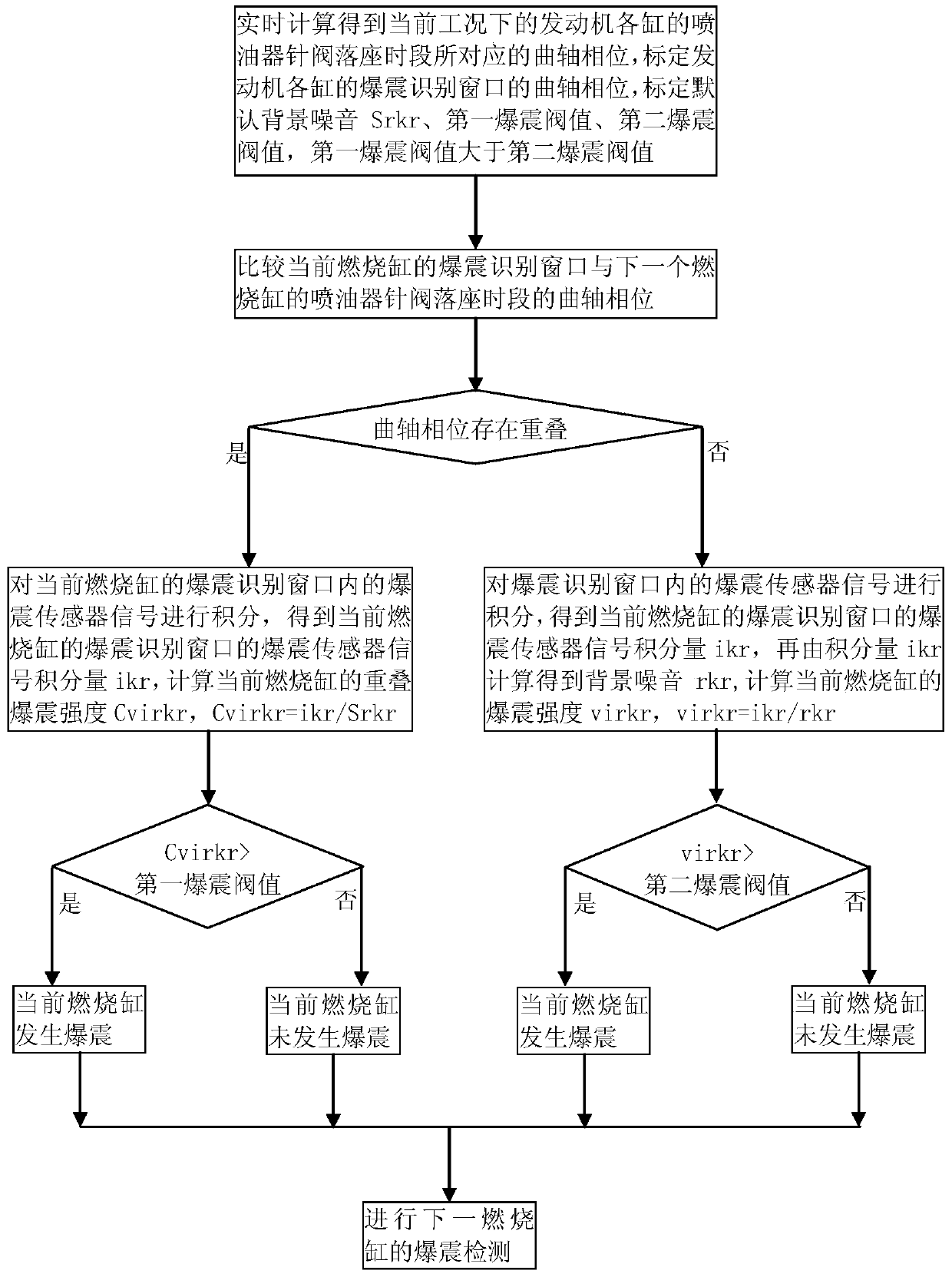

[0042] engine knock detection methods such as figure 1 shown, including the following steps:

[0043] 1. Calculate the crankshaft phase corresponding to the injector needle valve seating period of each cylinder of the engine under the current working conditions in real time, calibrate the crankshaft phase of the knock recognition window of each cylinder of the engine, and calibrate the default background noise Srkr and the first knock threshold, the second knock threshold, the first knock threshold is greater than the second knock threshold;

[0044] 2. Compare the knock recognition window of the current combustion cylinder with the crankshaft phase of the injector needle valve seating period of the next combustion cylinder;

[0045] 3. If the seating period of the injector needle valve of the next combustion cylinder overlaps with the crankshaft phase of the knock identification window of the current combustion cylinder, it is judged that the noise of the injector seating en...

Embodiment 2

[0054] Based on the engine knock detection method of Embodiment 1, in step 1, the first angle and the second angle are also calibrated, and the first angle is smaller than the second angle;

[0055] In step five, if it is detected that knocking occurs in the current combustion cylinder, the ignition angle of the current combustion cylinder is delayed by less than the first angle; if it is detected that no knocking occurs in the current combustion cylinder, the ignition angle of the current combustion cylinder is not delayed;

[0056] In step seven, if it is detected that knocking occurs in the current combustion cylinder, the ignition angle of the current combustion cylinder is delayed by less than the second angle; if it is detected that knocking does not occur in the current combustion cylinder, the ignition angle of the current combustion cylinder is not delayed.

[0057] In the engine knock detection method of Embodiment 2, if it is detected that the current combustion cyli...

Embodiment 3

[0059] Based on the engine knock detection method of embodiment one, in step one, the first time and the second time are also calibrated, and the first time is less than the second time;

[0060] In step 4, the knock sensor signal integral ikr of the knock recognition window of the current combustion cylinder is filtered in the first time, and the current cycle background noise of the knock recognition window of the current combustion cylinder is calculated to complete the background noise learning;

[0061] In step six, the knock sensor signal integral ikr of the knock recognition window of the current combustion cylinder is filtered in a second time, and the current cycle background noise of the knock recognition window of the current combustion cylinder is calculated to complete background noise learning.

[0062] In the engine knock detection method of the third embodiment, when the fuel injector seating noise enters the knock identification window of the current combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com