Control Method of Constant Pressure Air Supply of Multistage Centrifugal Air Compressor

An air compressor and control method technology, applied in the direction of engine control, pump control, mechanical equipment, etc., can solve problems such as surge shutdown, overcurrent shutdown, and constant air supply on the gas site, and achieve the effect of stabilizing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

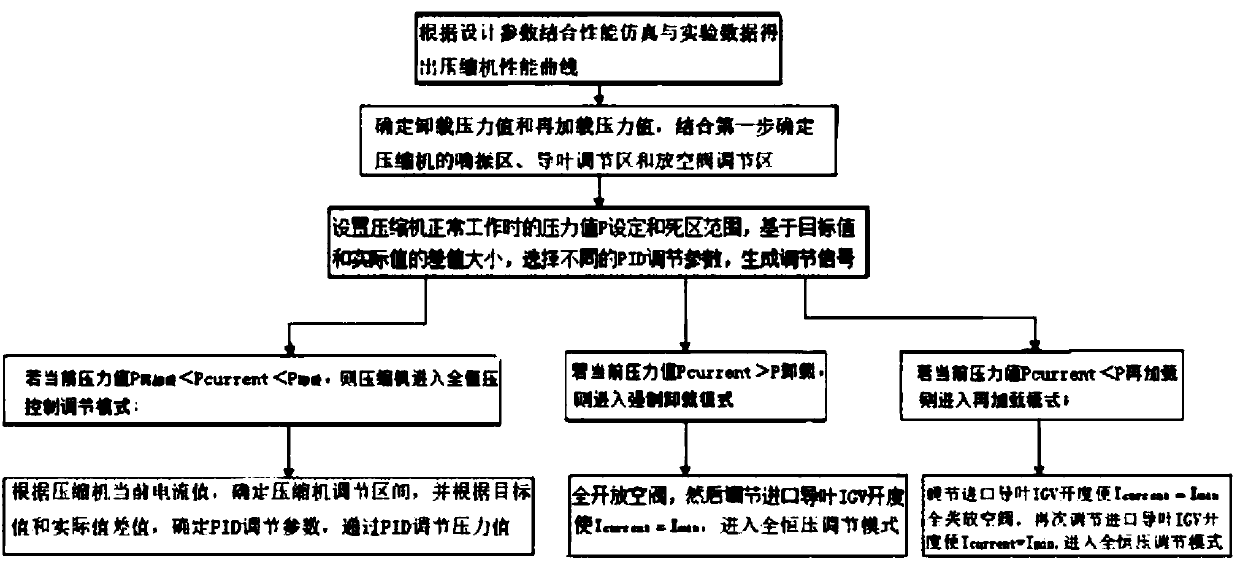

[0028] see figure 1 As shown, the control method for constant-pressure air supply of a multi-stage centrifugal air compressor is characterized in that it includes the following steps:

[0029] The first step is to obtain the performance curve of the multi-stage compressor according to the design parameters of the multi-stage compressor combined with performance simulation and experimental data;

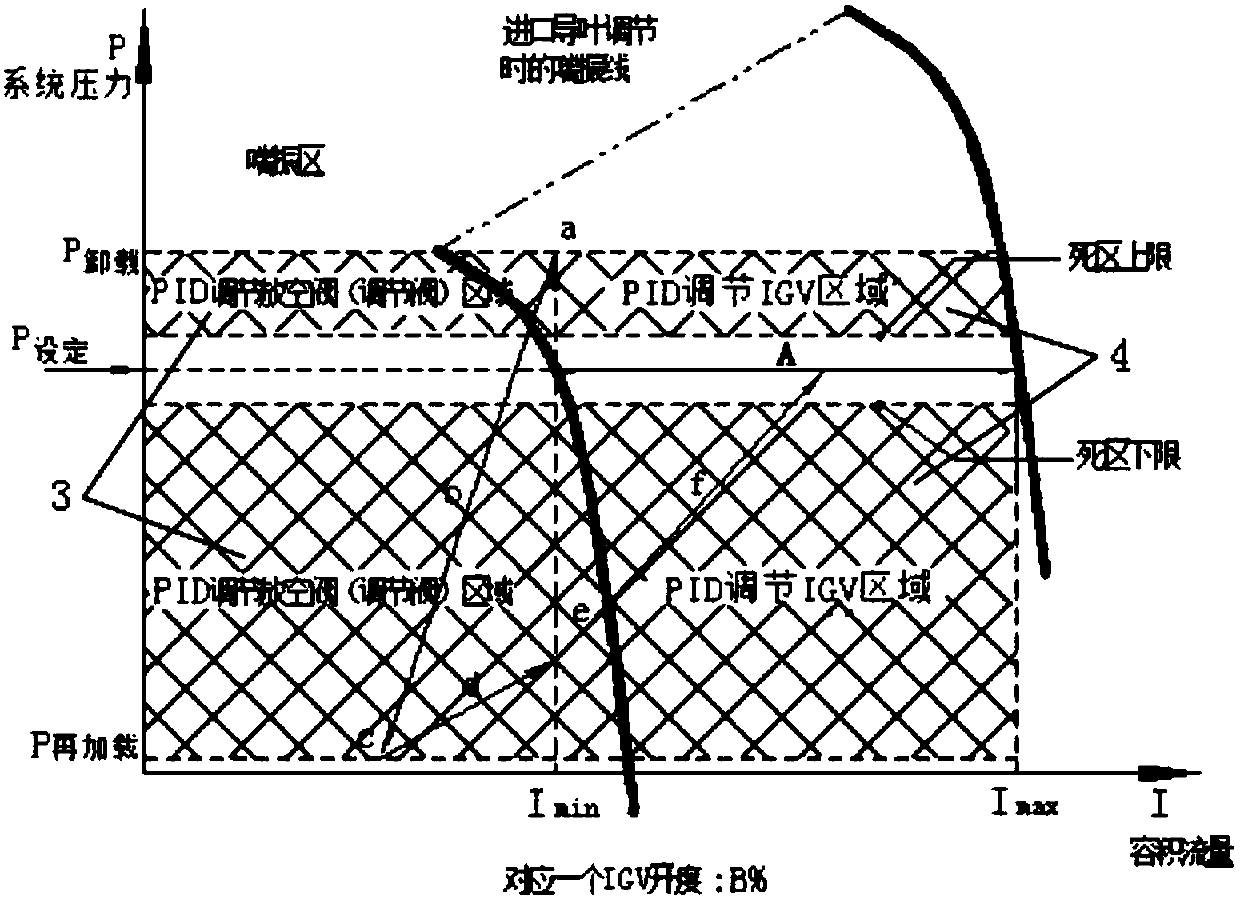

[0030] The second step is to determine the unloading pressure value and reloading pressure value, combined with the first step to determine the surge area, guide vane adjustment area and vent valve adjustment area of the multi-stage compressor;

[0031] The third step is to set the set pressure value P when the compressor works normally. 设定 and dead zone range, based on the difference between the target value and the actual value, select different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com