A construction machinery hydraulic oil return control circuit and its control method

A technology for oil return control and construction machinery, applied in mechanical equipment, servo meter circuits, fluid pressure actuating devices, etc., can solve the problems of high back pressure, affecting the temperature rise of the hydraulic system, energy loss, etc., to achieve reasonable energy flow, Increase oil return resistance and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

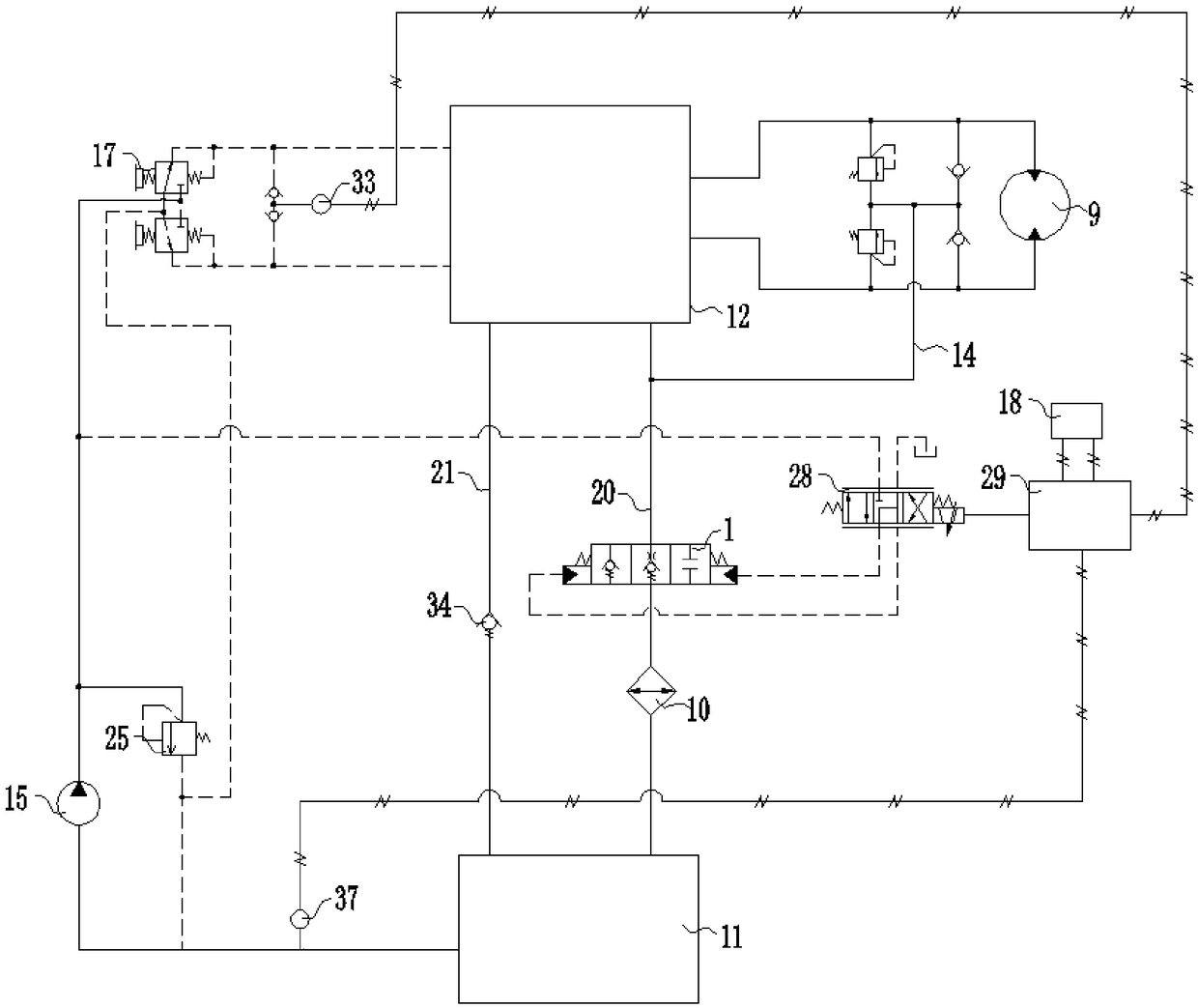

[0023] Such as figure 1 As shown, the hydraulic multi-way valve group 12 is used to control the oil in and out of the entire hydraulic system. The main oil circuit of the multi-way valve group 12 returning oil to the hydraulic oil tank 11 has a first oil return line 20 and a second oil return line 21. The oil return control valve 1 and the radiator 10 are installed on the first oil return circuit 20. The oil return control valve 1 is a three-position two-way hydraulic control valve. The function of the right position realizes conduction but has a certain oil return resistance or the pressure range is between 1bar-4bar, especially 2.5bar. The function of the right position is cut-off or the oil return resistance is very high, for example, the oil return resistance is higher than 5bar and lower than 12bar. Especially 10bar. The second oil return circuit 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com