Locknut

An anti-loosening nut and anti-loosening technology, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of weakening the anti-loosening effect of the double-nut structure, failure of the anti-loosening of the double-nut structure, and difficulty in installation, and achieves the effect of small torque and anti-loosening effect Good, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

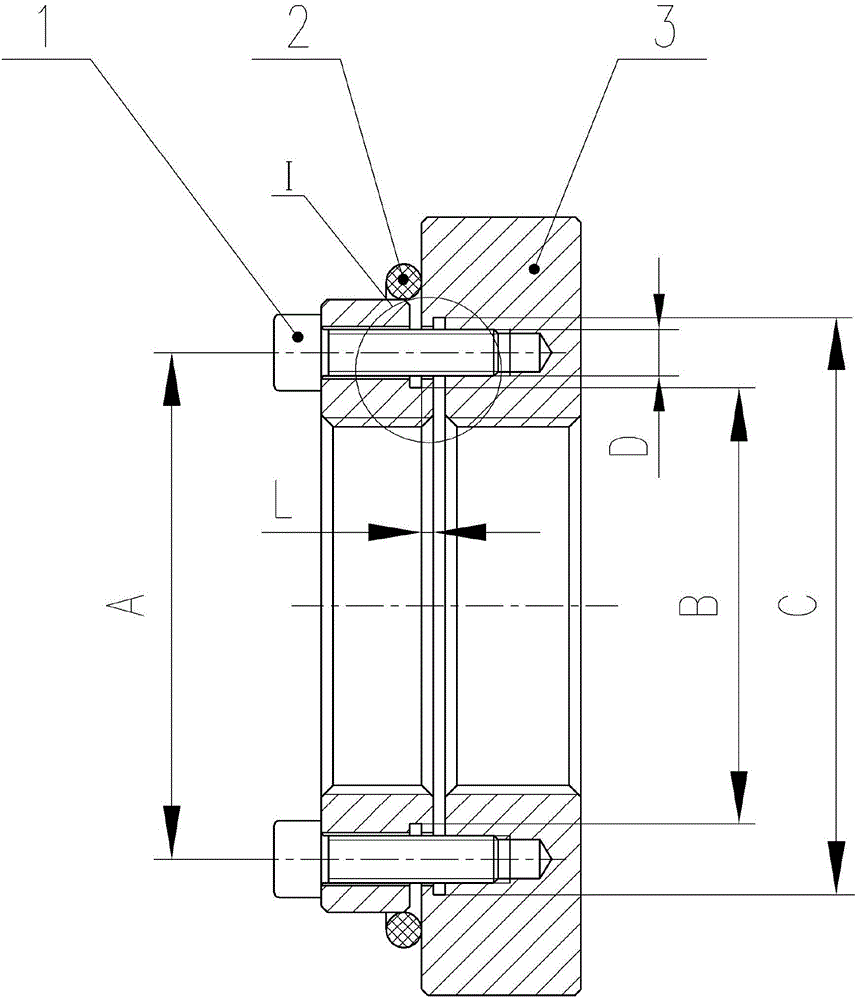

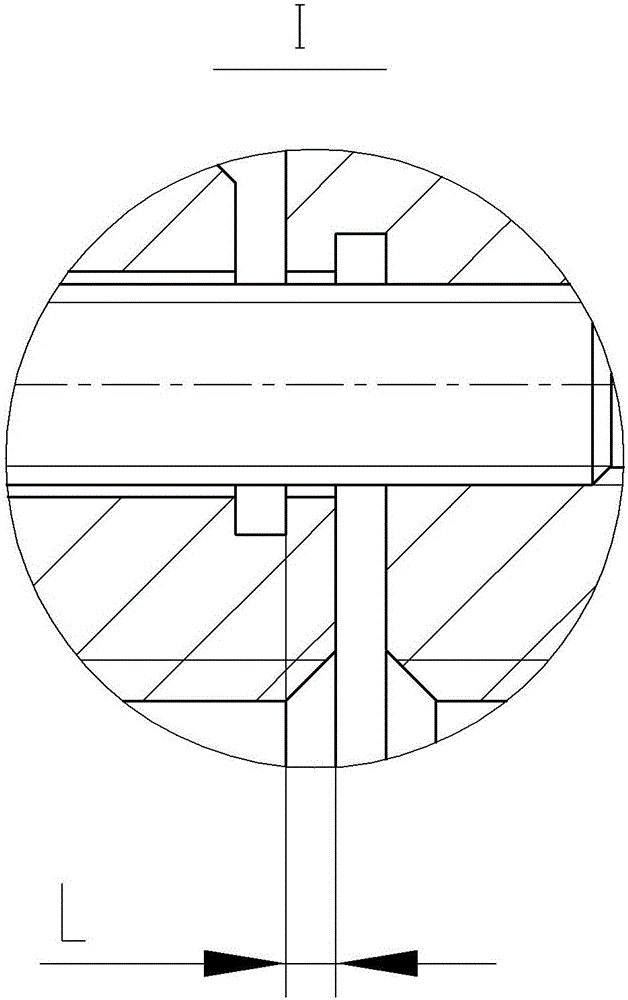

[0024] Such as Figure 1-3 As shown, the present embodiment provides a kind of anti-loosening nut; figure 1 As shown, the locknut in this embodiment at least includes a screw 1 , a dustproof ring 2 and a nut 3 . Among them, the screw 1 cooperates with the anti-loosening hole on the front end surface of the nut 3 to lock the nut; the dustproof ring 2 is installed on the groove on the outer ring of the nut 3 to prevent dust and other sundries from falling into the groove , thus affecting the normal use of the nut.

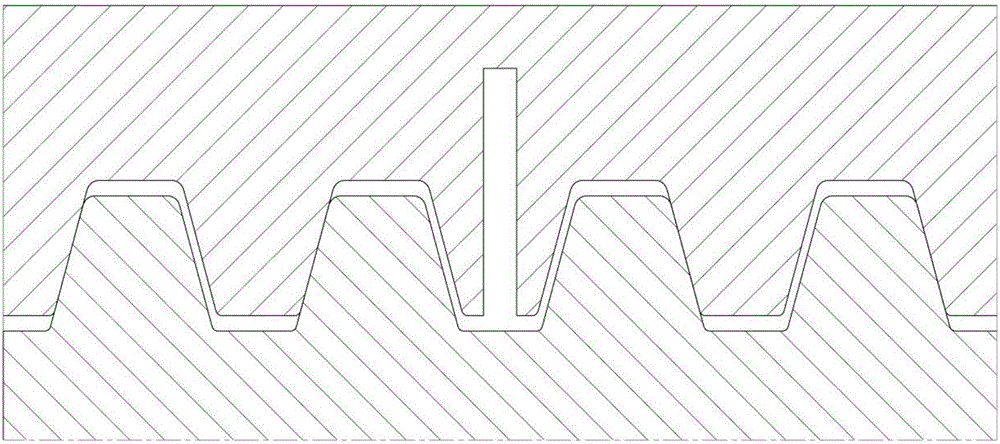

[0025] On the outer ring of the nut 3, there is a groove near the front side, the groove diameter B; on the inner ring of the nut 3, there is a groove near the rear side, the groove diameter C, the groove divides the inner thread of the nut into two sections, front and back , the distance between the inner and outer grooves is L.

[0026] The diameter of the groove on the outer ring of the nut 3 is BA+D; and the distance L between the two grooves cannot be too lar...

Embodiment 2

[0034] This embodiment provides a lock nut. This embodiment provides a lock nut. As shown in the figure, the lock nut of this embodiment at least includes a screw, a dust seal and a nut. Among them, the screw cooperates with the anti-loosening hole on the front side of the nut to lock the nut; the dustproof ring is installed on the groove on the outer ring of the nut to prevent dust and other sundries from falling into the groove, thereby affecting the nut. normal use.

[0035] On the outer ring of the nut, there is a groove near the front side, the groove diameter B; on the inner ring of the nut, there is a groove near the back side, the groove diameter C, the groove divides the nut internal thread into two sections, the inner and outer The distance between the two grooves is L.

[0036] The diameter of the groove on the outer ring of the nut is BA+D.

[0037] The middle of the nut is a threaded through hole, and several anti-loosening holes are evenly distributed on the ci...

Embodiment 3

[0043] This embodiment provides a locknut; the locknut in this embodiment at least includes a screw, a dustproof ring and a nut. Among them, the screw cooperates with the anti-loosening hole on the front side of the nut to lock the nut; the dustproof ring is installed on the groove on the outer ring of the nut to prevent dust and other sundries from falling into the groove, thereby affecting the nut. normal use.

[0044] On the outer ring of the nut, there is a groove near the front side, the groove diameter B; on the inner ring of the nut, there is a groove near the back side, the groove diameter C, the groove divides the nut internal thread into two sections, the inner and outer The distance between the two grooves is L.

[0045] The diameter of the groove on the outer ring of the nut is BB, and C is not greater than A+D.

[0046] The middle of the nut is a threaded through hole, and several anti-loosening holes are evenly distributed on the circumferential direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com