A kind of coptx nanocomposite structure electromagnetic storage device and preparation method

A storage device and nano-composite technology, applied in static memory, electric solid-state devices, digital memory information, etc., to achieve excellent storage performance, conformality and controllability guarantee, and excellent resistive storage function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

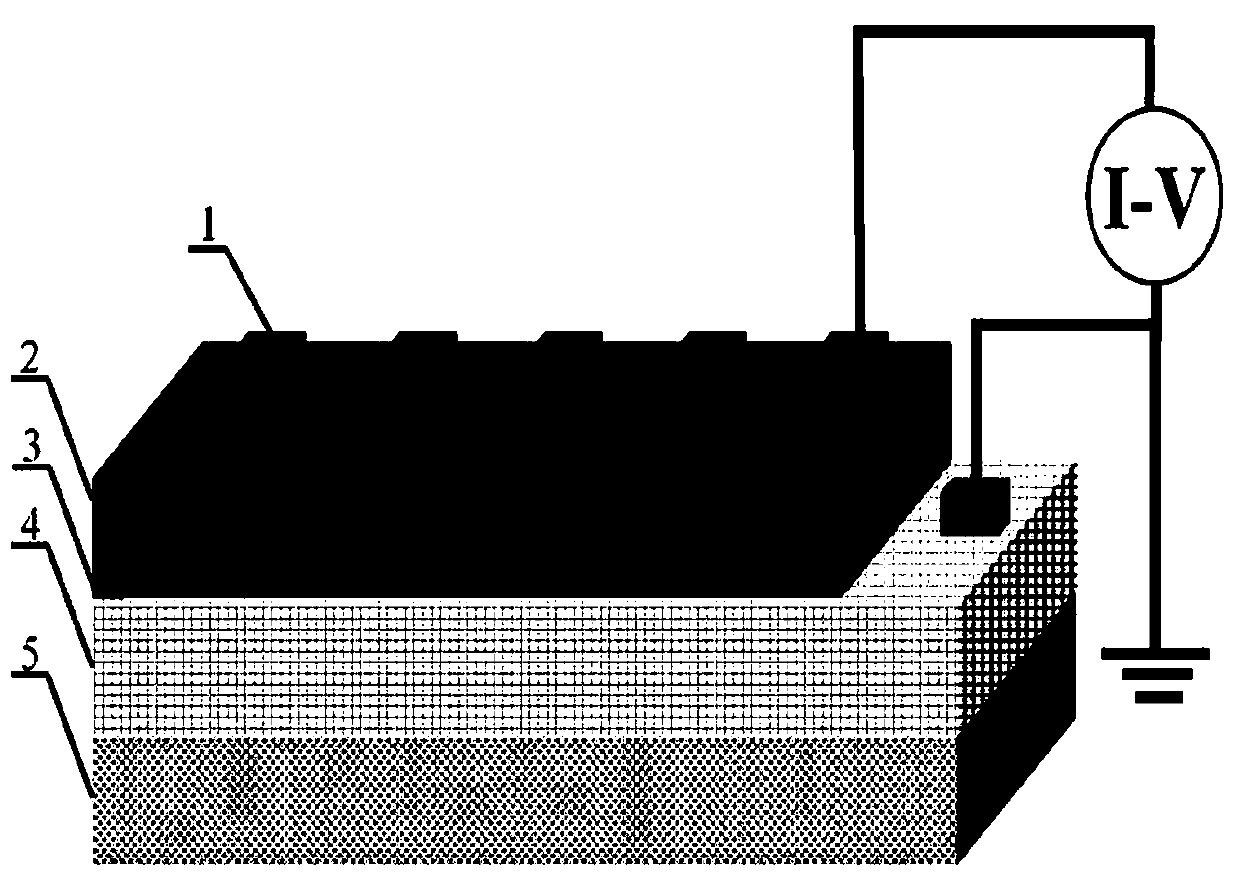

[0039] (1) With the clean silicon wafer 5 as the substrate, the lower electrode 4 is firstly prepared by plasma-enhanced atomic layer deposition, and the lower electrode TiN is prepared. The specific steps are as follows:

[0040] TiN growth temperature is 400°C, with TiCl 4 , NH 3 Plasma is used as Ti source and nitrogen source respectively, where TiCl 4 The pulse time is 0.1 seconds, the carrier gas is high-purity nitrogen (99.999%), and it is used as a cleaning gas at the same time, and the cleaning time is 4 seconds; NH 3 The carrier gas of the plasma is high-purity argon (99.999%), and its pulse time is 24 seconds. The cleaning time of high-purity nitrogen as the cleaning gas is 6 seconds. TiCl 4 The source temperature is room temperature. In this embodiment, the thickness of TiN is 30nm;

[0041] (2) CoPt was grown on the lower electrode TiN layer by plasma-enhanced atomic layer deposition x Magnetic nanocrystalline layer 3;

[0042] CoPt x The nanocrystal growth ...

Embodiment 2

[0053] (1) Using a clean silicon wafer as the substrate, firstly prepare the lower electrode TiN with a thickness of 120 nm by using plasma-enhanced atomic layer deposition, and the preparation method is the same as step (1) in Example 1;

[0054] (2) CoPt was grown on the lower electrode TiN layer by plasma-enhanced atomic layer deposition x Nanocrystals, the preparation method of which is the same as step (2) in Example 1, the cycle ratio of Co:Pt is 1:1, and the number of cycles is 100 cycles;

[0055] (3) Second, hafnium oxide thin film was grown to form the resistive switch layer. The atomic layer deposition process conditions were as follows: the growth temperature was 250°C, tetrakis-(dimethylethylamino hafnium) and secondary deionized water were used as Hf source and oxygen source respectively, each The pulse time of Luyuan is 0.1 seconds, the carrier gas is high-purity nitrogen (99.999%) and it is also used as cleaning gas, and the cleaning time is 4 seconds. Tetra-(...

Embodiment 3

[0063] (1) With a clean silicon wafer as the substrate, the lower electrode TiN was first prepared by plasma-enhanced atomic layer deposition. The specific steps are as follows:

[0064] TiN growth temperature is 400°C, with TiCl 4 , NH 3 Plasma is used as Ti source and nitrogen source respectively, where TiCl 4 The pulse time is 0.1 seconds, the carrier gas is high-purity nitrogen (99.999%), and it is used as a cleaning gas at the same time, and the cleaning time is 4 seconds; NH 3 The carrier gas of the plasma is high-purity argon (99.999%), and its pulse time is 24 seconds. The cleaning time of high-purity nitrogen as the cleaning gas is 6 seconds. TiCl 4 The source temperature is room temperature. In this embodiment, the thickness of TiN is 200nm;

[0065] (2) CoPt was grown on the lower electrode TiN layer by plasma-enhanced atomic layer deposition x nanocrystalline layer;

[0066] CoPt x The nanocrystal growth temperature was 300°C, and the PtMeCpMe 3 , CoCp(CO) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com