Disc brake, more particularly for commercial vehicles

A disc brake, disc brake technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of assembly and disassembly cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

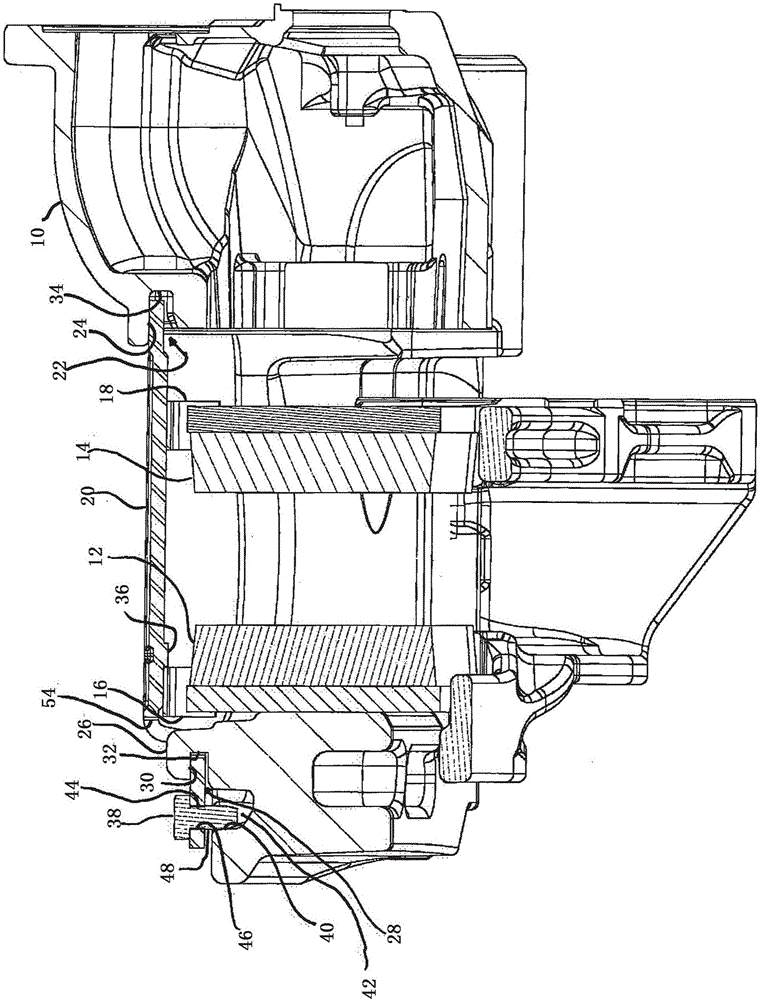

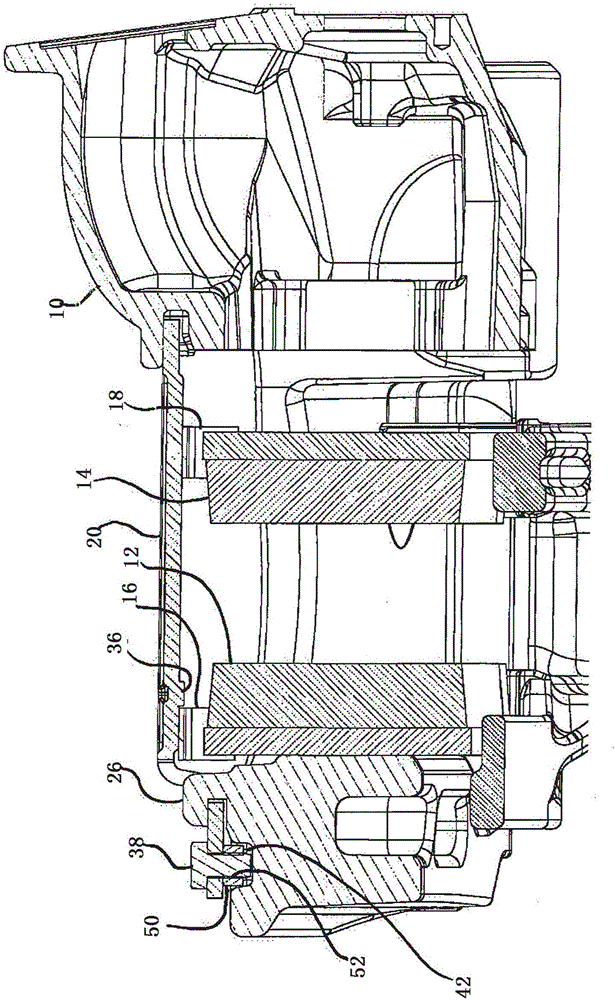

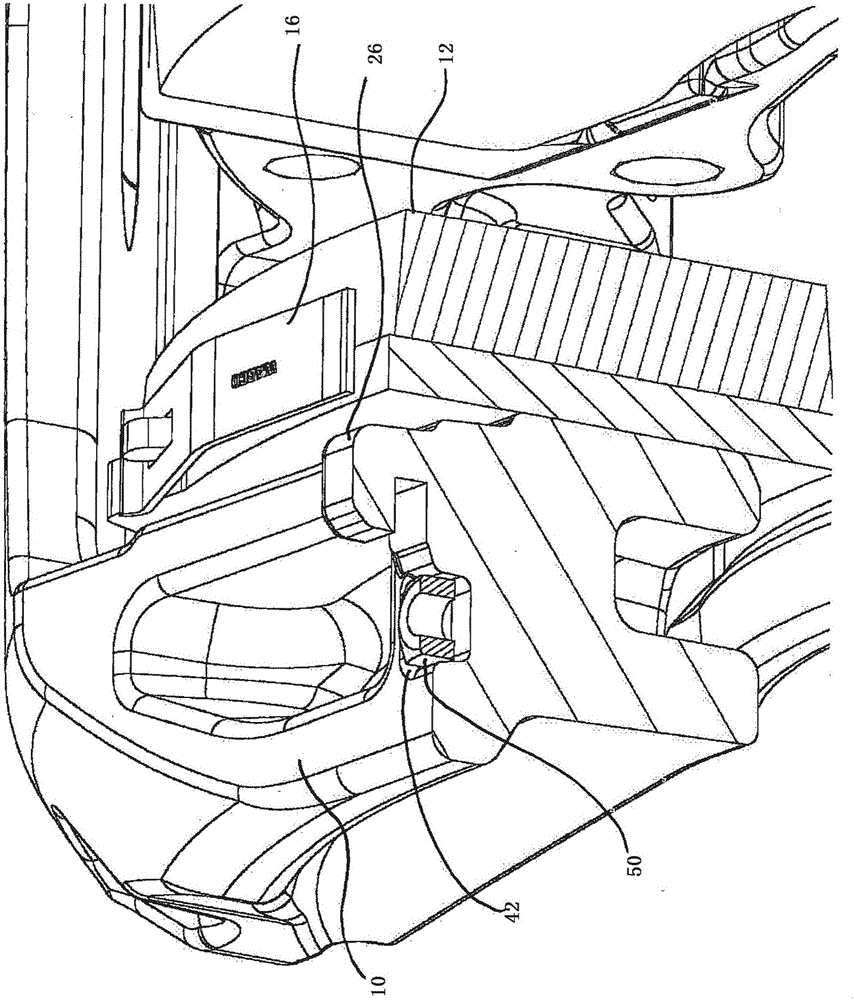

[0029] Belonging to the disc brake according to the invention is the figure 1 In the first embodiment shown there is a brake caliper 10 , two brake pads 12 , 14 , two hold-down springs 16 , 18 and hold-down bow 20 . Press the bow 20 in the radial direction, that is to say in figure 1 The middle is downward, so that the compression springs 16 and 18 are pretensioned. Between the brake pads 12 and 14 there is a brake disc (not shown). The pressing bow 20 also serves as a loss prevention device for the brake pads 12 and 14 , in particular in the event of a breakage of the pressing springs 16 , 18 .

[0030] The pressing bow is held on the pressing side in a slot 22 whose radially outer wall 24 absorbs the prestressing force.

[0031] On the rim side, a projection 26 is formed on the brake caliper 10 , which likewise has a slot 28 . The radially outer wall 30 of the slot 28 in turn serves to absorb the reaction force of the prestressing force.

[0032] In the two slots 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com