Male die movable type fine punching die

A mobile, fine punching die technology, used in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problem of rough cutting end face of workpieces, and achieve the effect of improving processing quality, improving plasticity, and suppressing shear end face cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

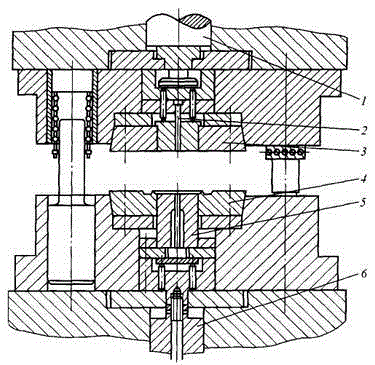

[0012] The reference signs in the drawings of the description include: upper plunger 1 , punching punch 2 , blanking die 3 , ring gear platen 4 , punch and die 5 , and slide block 6 .

[0013] The embodiment is basically as attached figure 1 As shown: the movable fine punching die of this embodiment, the upper part of the upper die base is provided with an upper platen, and the upper platen is opened with a stepped hole with a small upper part and a larger lower part, the upper plunger 1 is set in the upper stepped hole, and the upper pad is set In the lower step hole, the lower end of the upper plunger 1 is provided with a connecting block integrated with it, the connecting block passes through the upper pad, the lower end of the connecting block is fixed with the push plate, the push plate is fixed with two push rods, and the lower end of the push rod is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com