Opposite-control type safety socket

A technology of safety sockets and sockets, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems that safety sockets cannot be realized, the cost of safety sockets is high, and the protection effect is not good, so as to prevent children from electric shock accidents, simple structure, and convenient Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

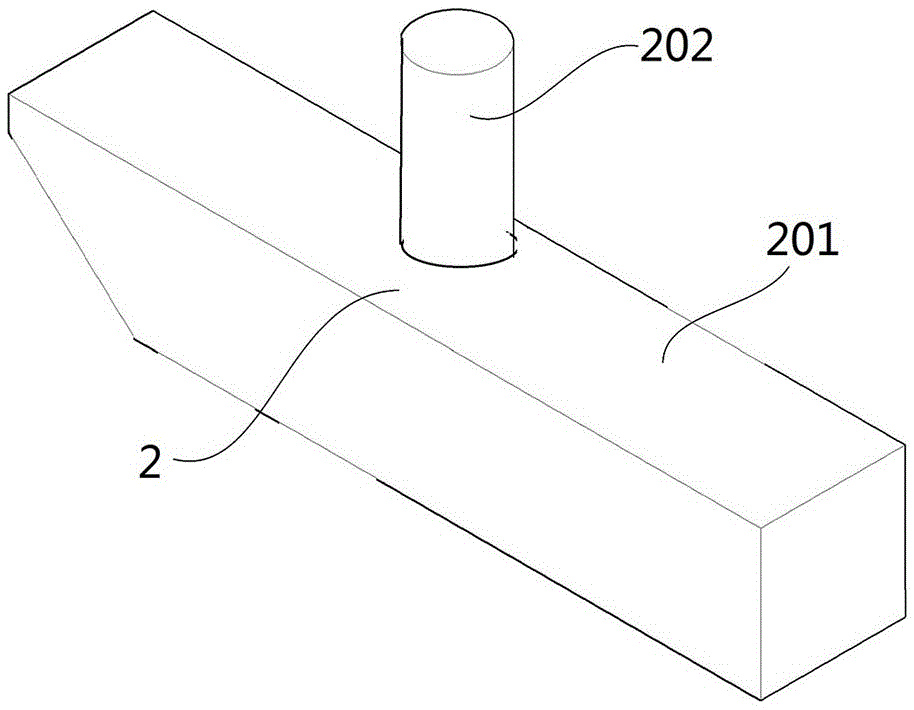

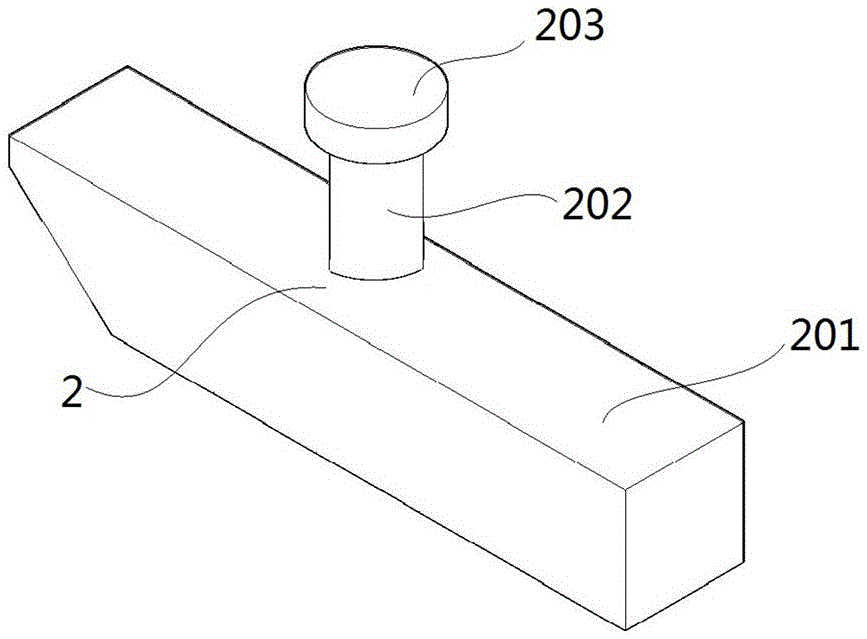

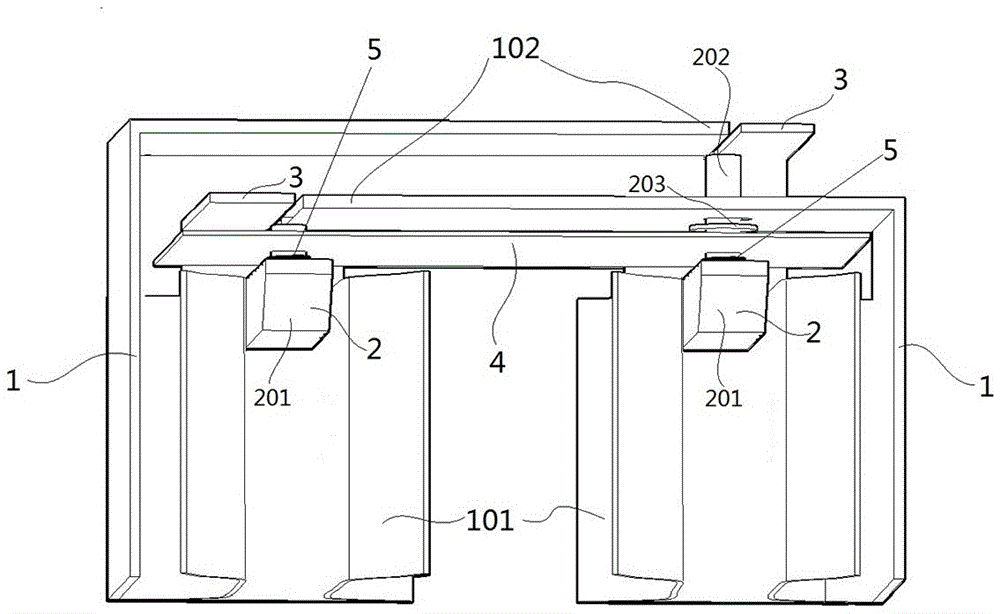

[0033] Such as figure 1 As shown, a control type safety socket of this embodiment includes a housing (6), a socket contact piece (1), an incoming line contact piece (3) and a linkage contact device; the housing (6) is divided into an upper The shell (601), the middle shell; the upper shell (601) is provided with a socket, and the inner side is provided with a slot (6011) for clamping the power baffle (4), and the upper end of the power baffle (4) is snapped into the slot ( 6011) to enhance the stability of the power baffle (4); the linkage contact device includes a power slider (201), a tail, a spring (5) and a power baffle (4), and the power slider (201) is an insulator , along the plug insertion direction is conducive to the smooth surface of the plug insertion, the power slider (201) is located in the seat body (101) close to the socket contact pin part (102) side; the tail part includes the tail rod (202) and the limit part (203), located on the side where the power slide...

Embodiment 2

[0035] The specific structure of the pair-controlled safety socket of this embodiment is basically the same as that of Embodiment 1, the difference is that: the outer shell (6) includes an upper shell (601), a middle shell and a lower shell, and the incoming line contacts ( 3) One end installed with terminals passes through the lower opening of the middle shell and is fixedly connected with the middle shell, and the lower shell is fixed at the bottom of the middle shell to protect and isolate the incoming line contact piece (3) and the wiring terminals, so that the socket structure is more compact .

Embodiment 3

[0037] The specific structure of the pair-controlled safety socket of this embodiment is basically the same as that of Embodiment 1, the difference is that: the contact piece (3) of the incoming line and the pin part (102) of the contact piece of the socket are located in the linkage contact device One side; the linkage contact device includes a power slider (201) and a tail, and the linkage contact device is fixedly connected with the incoming line contact (3) or the socket contact pin (102) through the tail, and through the linkage Move and squeeze to connect the incoming contact piece (3) with the pin part of the socket contact piece (102) to connect the circuit, and realize the reset by the elasticity of the incoming line contact piece (3) or the socket contact piece pin part (102) itself .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com