Safe electric kettle preventing risks

An electric kettle, a dangerous technology, applied in the field of electric kettles, can solve the problems of electric kettles such as circuit board short-circuit burnout, lid not completely closed, self-resetting, etc., to achieve good resilience, not easy to fall out, and increase life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

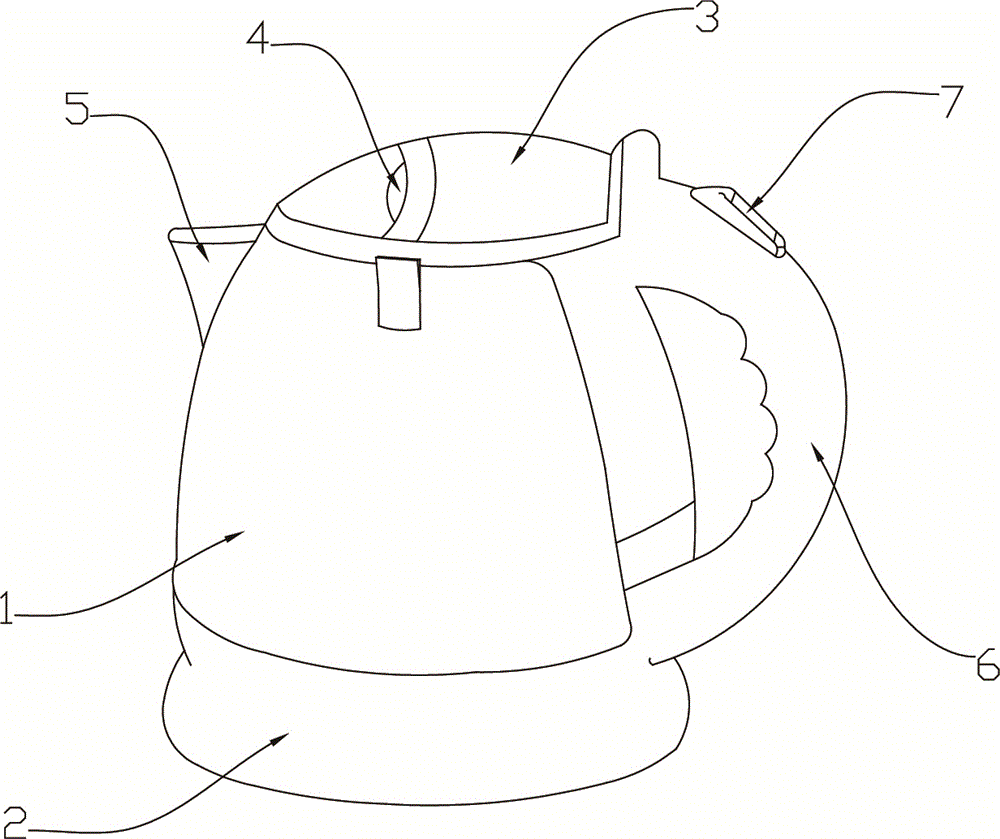

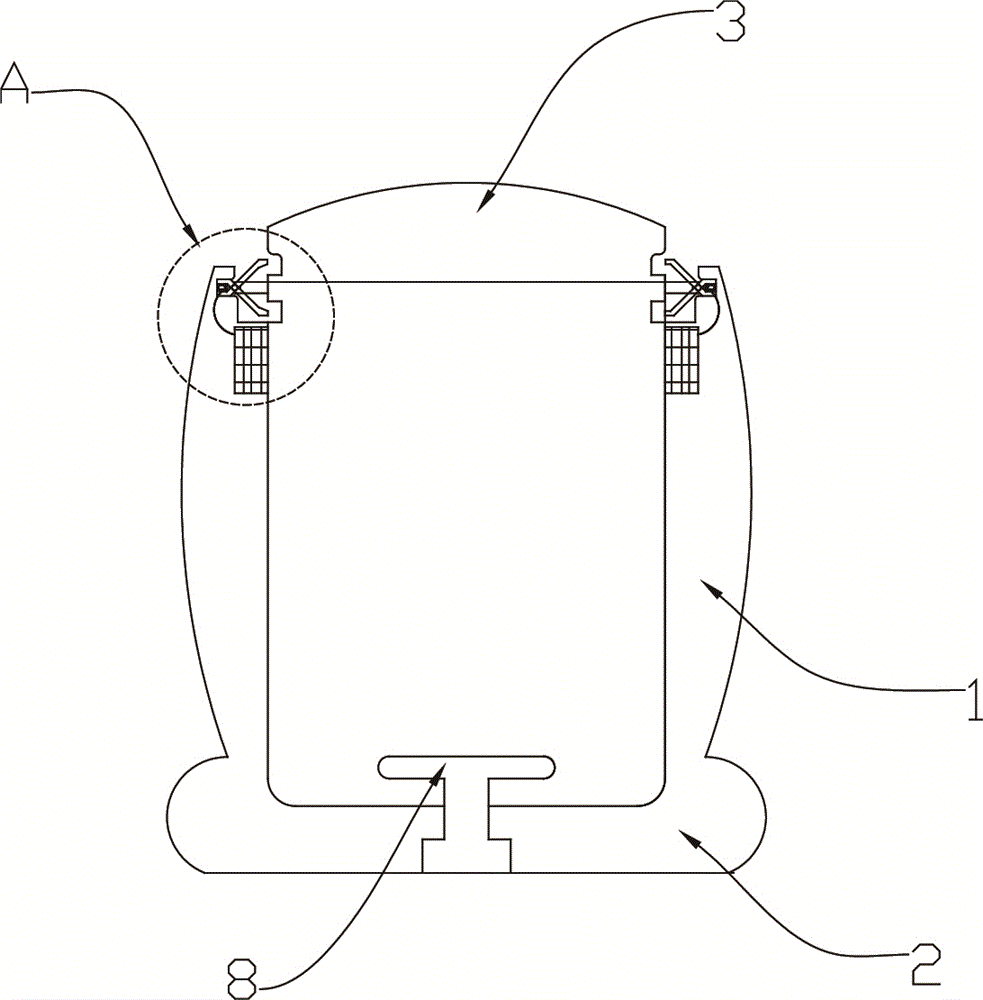

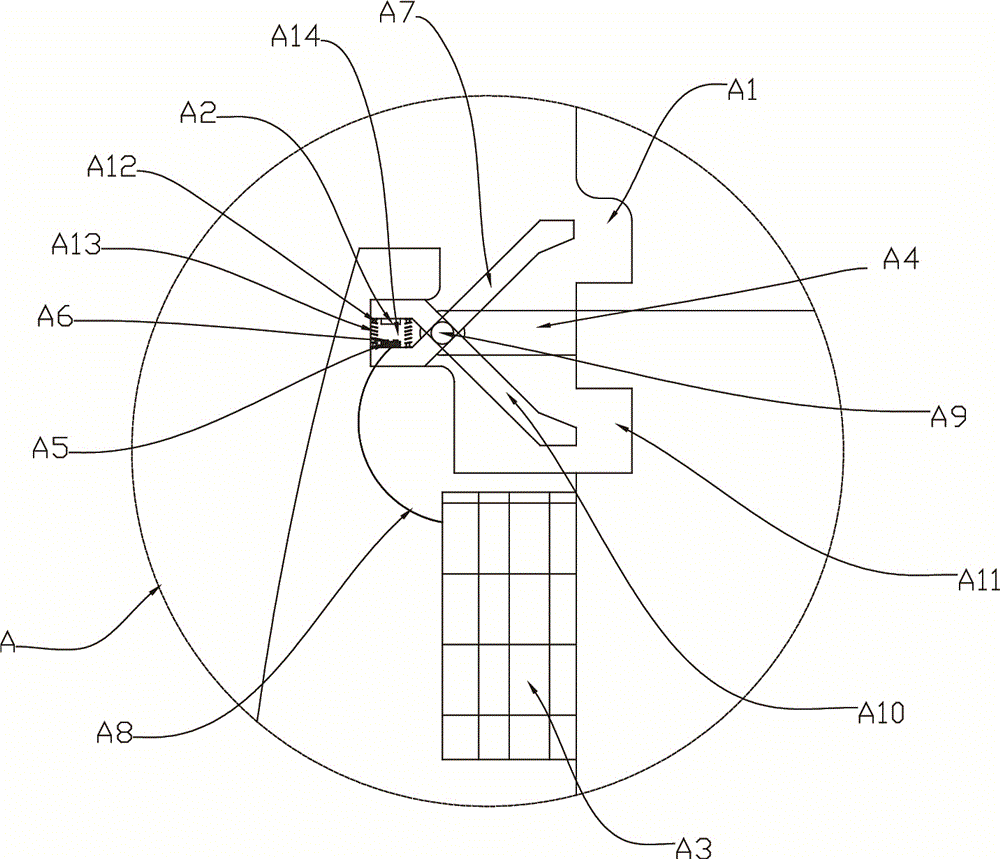

[0013] See Figure 1 to Figure 3 , an electric kettle for safe prevention of danger, comprising a kettle body 1, a lid 3, a lid switch 4, a spout 5, a handle 6, a kettle base 2, a switch 7, and a heating device 8, and the lid 3 is provided with Above the pot body 1, the pot base 2 is arranged below the pot body 1, the pot body 1 is also provided with a spout 5 and a pot handle 6, the switch 7 is arranged on the pot handle 6, and the heating device 8 is set on the pot base 2, and also includes an automatic closing device A, which includes a pot cover groove A1, a first pot body groove A11, a second pot body groove A14, a protruding block A4, an iron Sheet A2, thermoelectric power generation device A3, electromagnet A5, swing lower pressure rod A7, swing upper push rod A10, swing shaft A9, elastic reset member, electric wire A8, and a groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com