Sanitary product core material wood pulp cellulose applying device

A technology of wood pulp fiber and hygiene products, which is applied in the field of wood pulp fiber application device for core materials of hygiene products, which can solve the problems of unsatisfactory diversion effect, reverse osmosis effect and dryness of core materials of hygiene products, and achieve crushing Delicate, unimpeded conveying air duct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

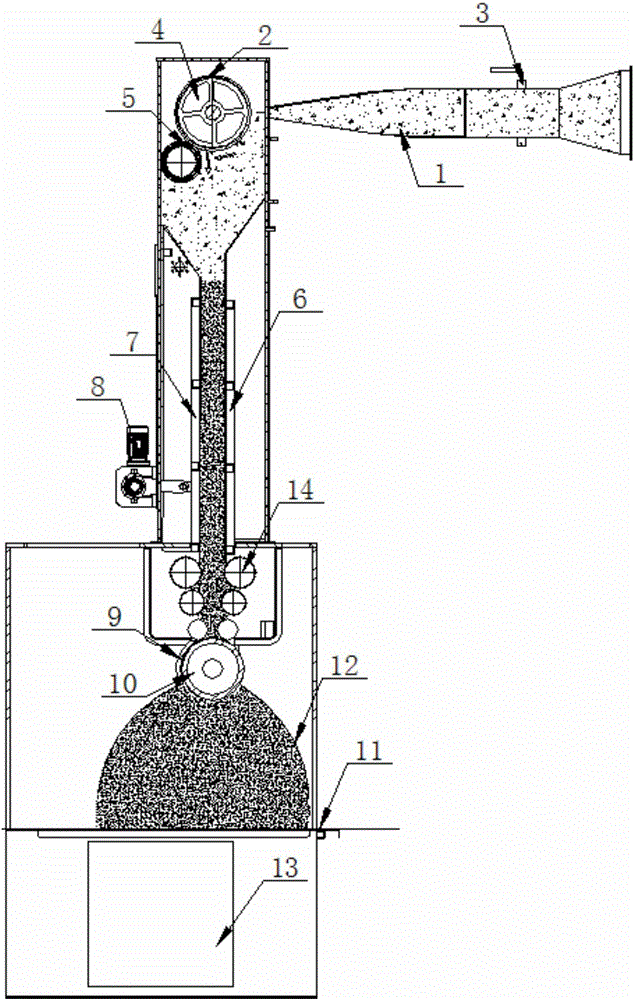

[0016] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as figure 1 As shown, a wood pulp fiber application device for the core material of hygiene products includes a wood pulp fiber conveying air duct 1 and a wood pulp fiber applying warehouse, the wood pulp fiber conveying air duct 1 is horizontally arranged, and the wood pulp fiber applicator The bin is vertically arranged, the wood pulp fiber conveying air duct 1 is connected to the upper end of the wood pulp fiber applying bin, and a squirrel cage roller 2 is arranged in the wood pulp fiber applying bin, and the squirrel cage roller 2 and the axial height of the squirrel cage roller 2 is the same as that of the wood pulp fiber conveying air duct 1, and the wood pulp fiber conveying air duct 1 is provided with a chamber blasting chamber for the wood pulp fiber The first fan 3, the end surface of the squirrel cage roller 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com