An active control hydraulic mount structure

A technology of hydraulic mounting and active control, applied in the direction of spring/shock absorber, shock absorber, shock absorber-spring combination, etc., can solve the problem of passive adjustment of the suspension cushion with the outside world.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

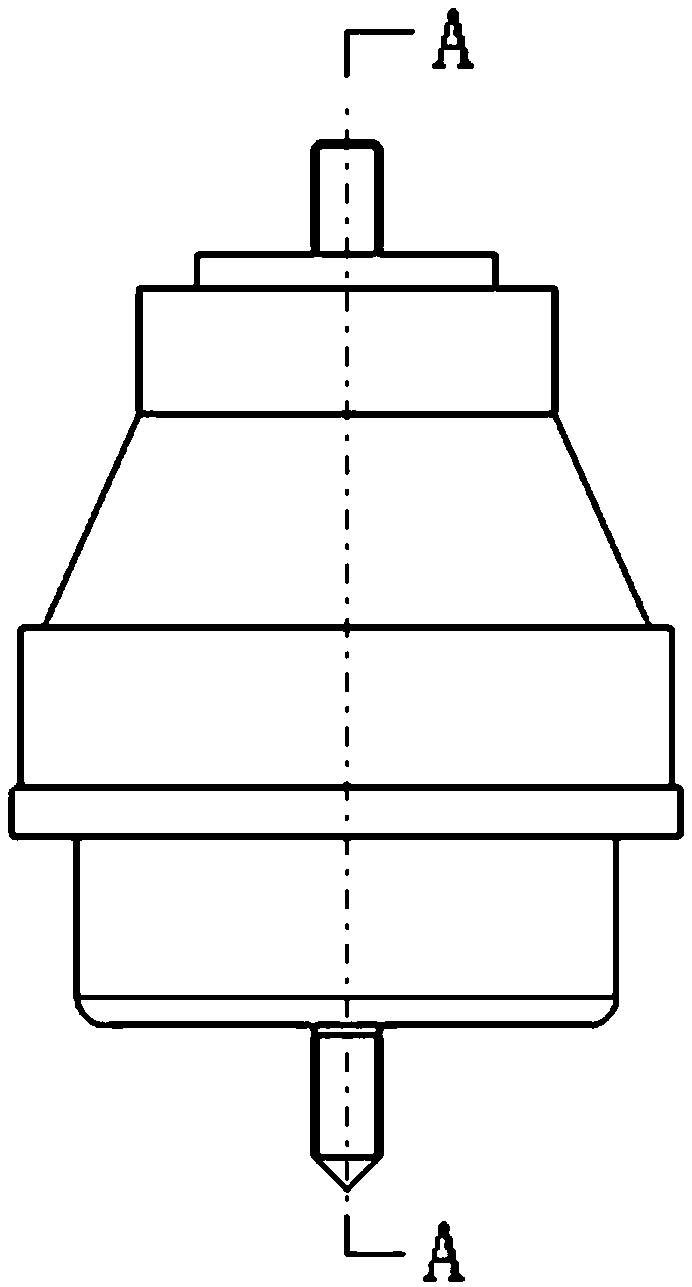

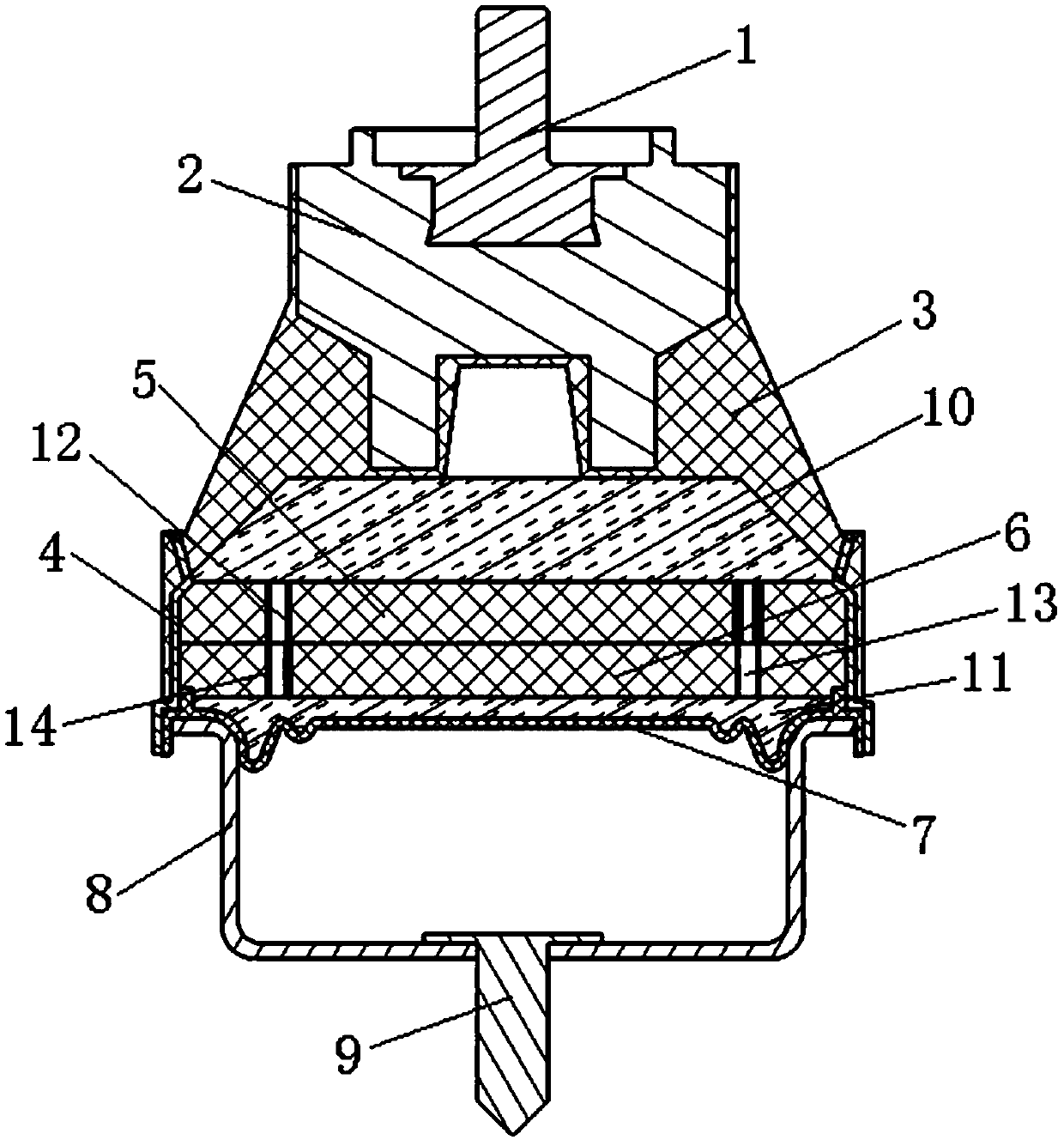

[0032] The present application provides an active control hydraulic mount structure, such as Figure 1 to Figure 6 As shown, it includes an upper mounting bolt 1, a metal frame 2, a rubber main spring 3, a suspension housing 4, a suspension bottom case 8, a lower mounting bolt 9, a rubber bottom film 7, an upper baffle 5 and a lower baffle 6, In each embodiment of the present application, the above components of the hydraulic mounting structure are all in the prior art, and the applicant will not describe them in detail here.

[0033] The upper mounting bolt is fixed on the metal skeleton, and the metal skeleton, the rubber main spring and the suspension shell are vulcanized into an integrated structure, which is also the prior art.

[0034] An upper partition plate and a lower partition plate are arranged in the suspension shell, and a rubber bottom film is arranged at the lower end of the suspension shell; However, the upper baffle plate and the lower baffle plate cannot be...

Embodiment 2

[0046] In this embodiment, other structures of the hydraulic mount are the same, and the only difference is the structure of the ring electrode.

[0047] In this embodiment, the ring electrode includes a first ring electrode and a second ring electrode, the first ring electrode is arranged in the upper inertia channel, and the second ring electrode is arranged in the lower inertia channel.

[0048] In this way, after the pressure signal transmitted by the sensor is transmitted to the control board, the magnitude and direction of the current of the corresponding annular electrode can be respectively controlled, which makes the control of the hydraulic mount more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com