Dredging type oil mist sealing method

A technology of oil mist and sealing cover, which is applied in the direction of engine sealing, engine components, engine lubrication, etc., can solve the problems of ineffective sealing, failure to achieve suction effect, difficulty in mastering, etc., and achieve the effect of avoiding oil shortage of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is mainly applied to a dredging-type oil mist sealing method used by a unidirectional rotating unit.

[0028] A dredging type oil mist sealing method, is characterized in that, comprises the following steps:

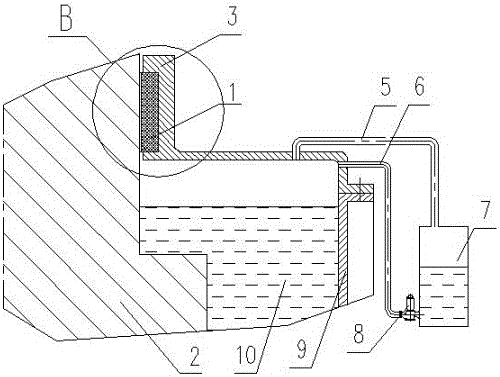

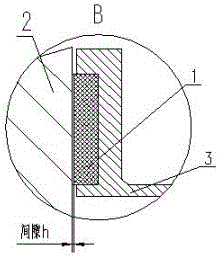

[0029] (1) An oil mist sealing device is installed on the oil tank; the oil mist sealing device includes a sealing cover, an oil collection tank 7, an oil suction pipe 6 and a sealing cover oil overflow pipe 5, and the rotation direction and the rotation of the rotating shaft 2 are provided on the sealing surface of the sealing cover The thread tooth structure 1 in the opposite direction, there is a gap between the thread tooth structure and the rotating shaft;

[0030] (2) When the unit is rotating, the oil pressure existing on the sealing surface is injected into the oil groove by utilizing the fluid viscosity, the rotation direction of the unit and the rotation direction of the thread teeth, and the pressure of the oil mist in the oil groove ris...

Embodiment 2

[0046] This embodiment is mainly applied to a dredge-type oil mist sealing method used in bidirectional rotating units.

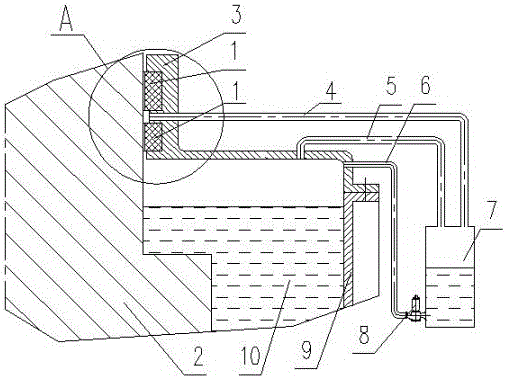

[0047] A dredging type oil mist sealing method, comprising the following steps:

[0048] (a1) Install an oil mist sealing device on the oil tank. The oil mist sealing device includes a sealing cover, an oil collection tank, a sealed interdental oil overflow pipe, an oil suction pipe and a sealing cover oil overflow pipe. There is a tooth rotation direction on the sealing surface of the sealing cover. The opposite two thread tooth structures, there is a gap between the two thread tooth structures and the rotating shaft; the heights of the two thread tooth structures are different, when the unit rotates, the thread tooth structure located at the bottom of the above two thread tooth structures and the rotation direction of the unit On the contrary, perform the following step (a2); when the unit rotates, and the lower thread tooth structure of the above two thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com