A multi-connection machine heat oil return control method and a multi-connection air conditioner

A technology of oil return control and multi-connection, applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve problems such as impact on user experience, pressure relief, and impact, and achieve the effect of avoiding oil shortage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

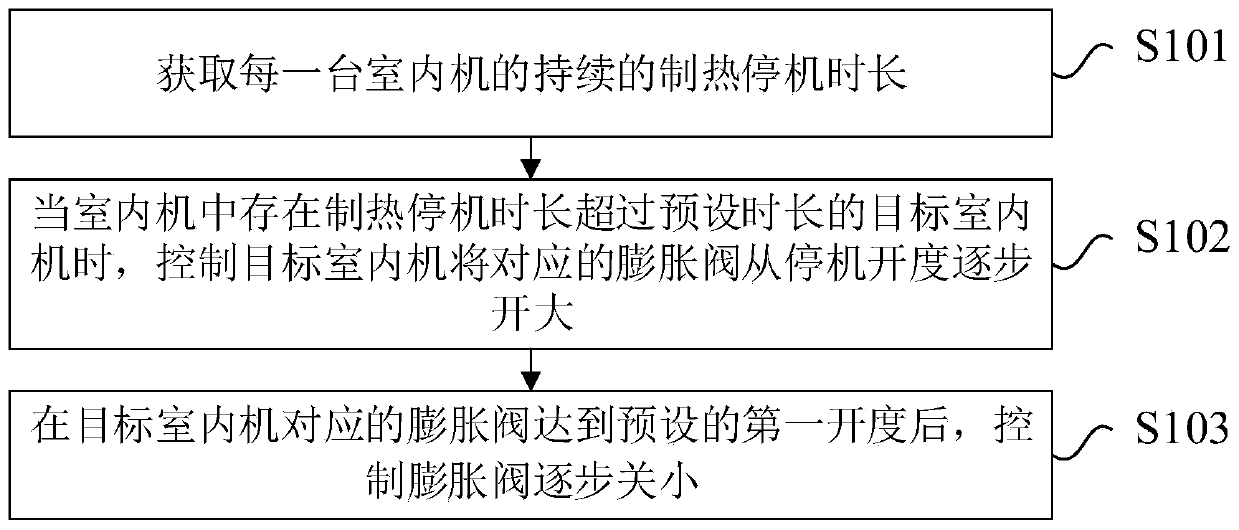

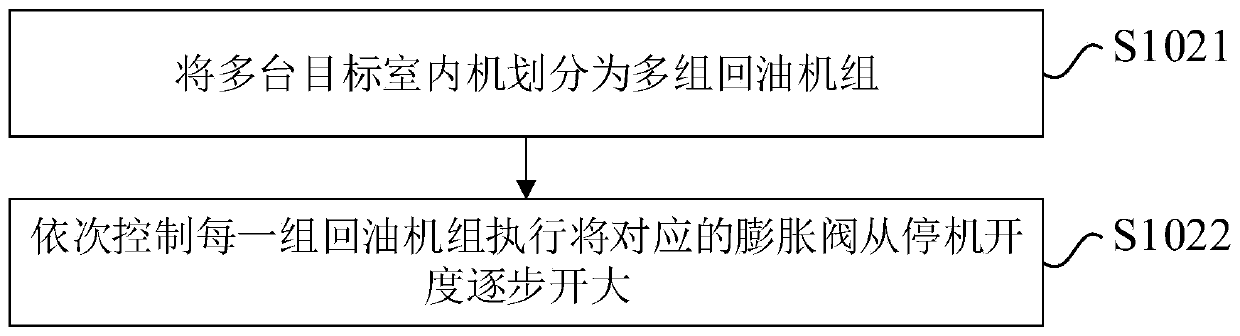

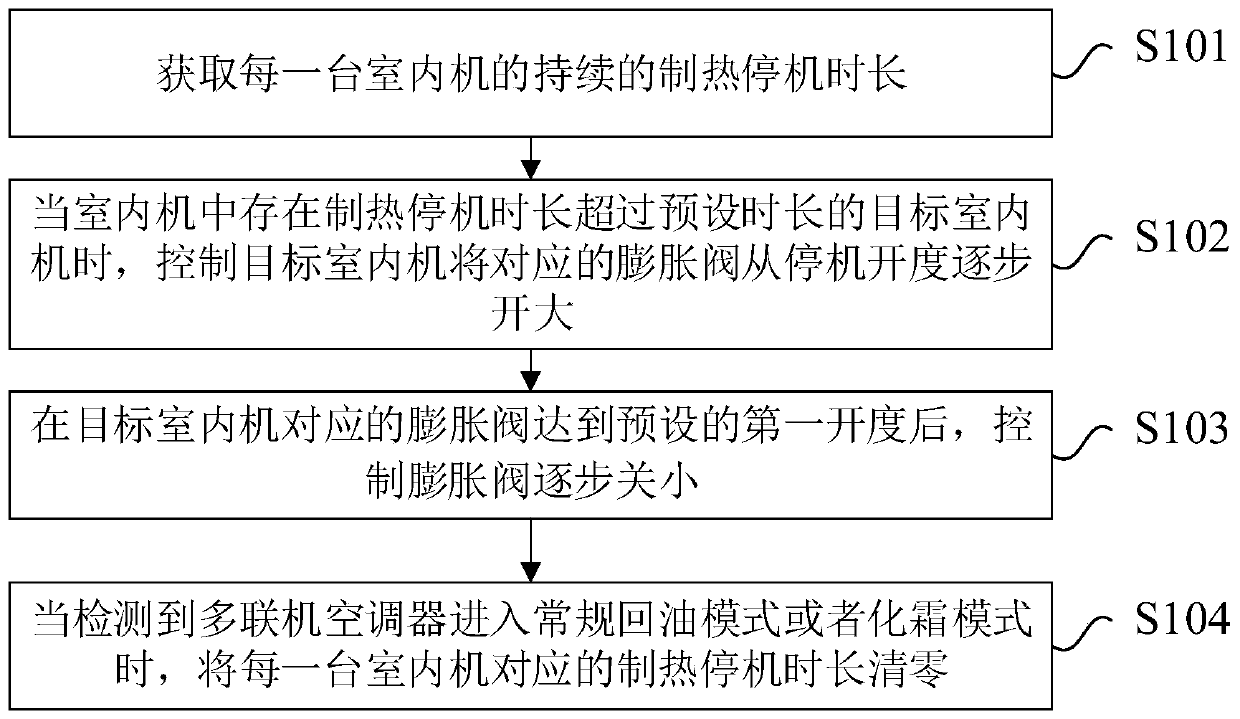

[0035] Please refer to figure 1 ,Such as figure 1 As shown, the embodiment of the present invention provides a multi-connection mechanism hot oil return control method, which is applied to a multi-connection air conditioner 1. The above-mentioned multi-connection mechanism heat oil return control method is used to realize timely and targeted oil return during the heating process of the multi-connected air conditioner 1, so as to ensure that the compressor does not have a shortage while not affecting the user's normal use of the air conditioner. The oil problem. Such as figure 1 As shown, the above-mentioned multiple mechanism hot oil return control method includes the following steps:

[0036] Step S101: Obtain the continuous heating shutdown duration of each indoor unit.

[0037] In the embodiment of the present invention, the above-mentioned multi-line air conditioner 1 may include multiple indoor units, and when the multi-line air conditioner 1 is operating in the heating mode,...

no. 2 example

[0072] Please refer to Figure 4 The embodiment of the present invention also provides a multi-line air conditioner 1. The multi-line air conditioner 1 may include: a collection unit 2 and a control unit 3, and the collection unit 2 is electrically connected to the control unit 3. Optionally, the collection unit 2 may include a timer, and the control unit 3 may include a main control CPU.

[0073] Optionally, the aforementioned collection unit 2 is used to obtain the continuous heating shutdown duration of each indoor unit.

[0074] Optionally, the aforementioned control unit 3 is configured to control the target indoor unit to gradually open the corresponding expansion valve from the shutdown opening when there is a target indoor unit whose heating shutdown duration exceeds a preset duration in the indoor unit Big.

[0075] Preferably, after the expansion valve corresponding to the target indoor unit reaches the preset first opening degree, the control unit 3 is specifically conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com