Oil injection device of ketone-benzene drum filter and automatic oil replenishing machine of oil injection device

An oil injection device and automatic oil replenishment technology, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of polluting the work site environment, economic losses, and polluting high-quality oil, so as to avoid oil leakage or lack of oil, The effect of high control accuracy and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

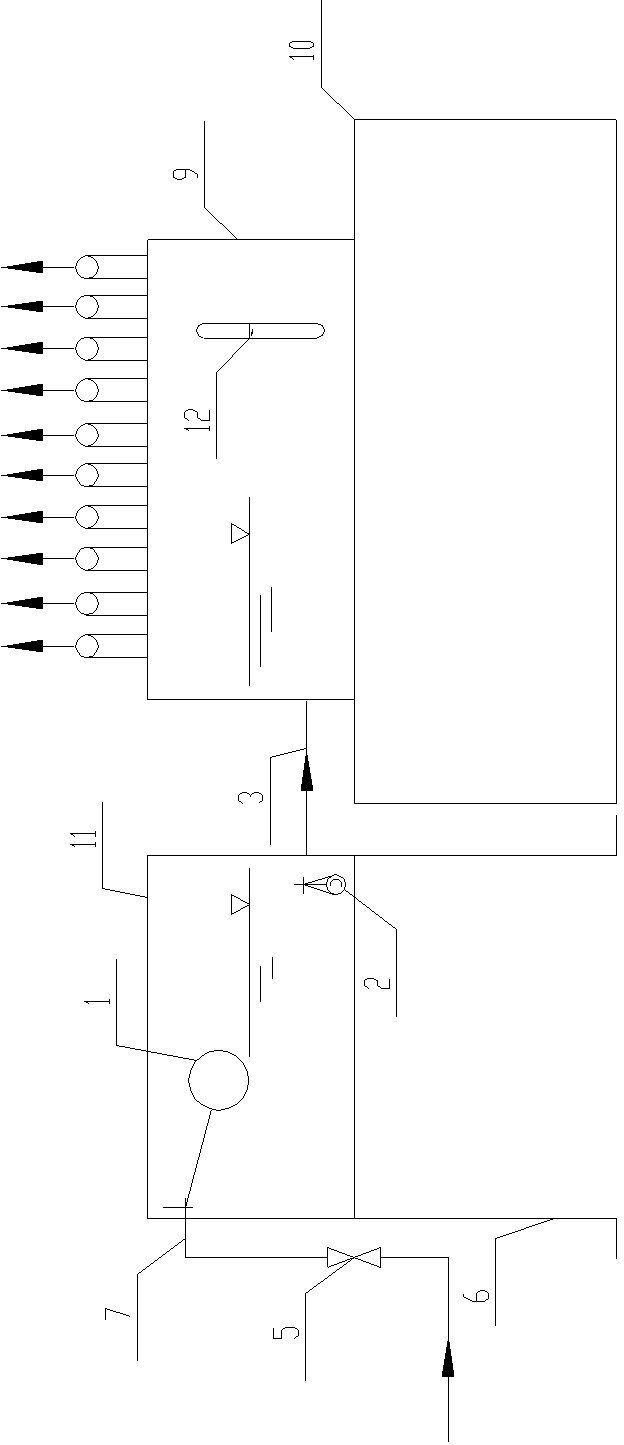

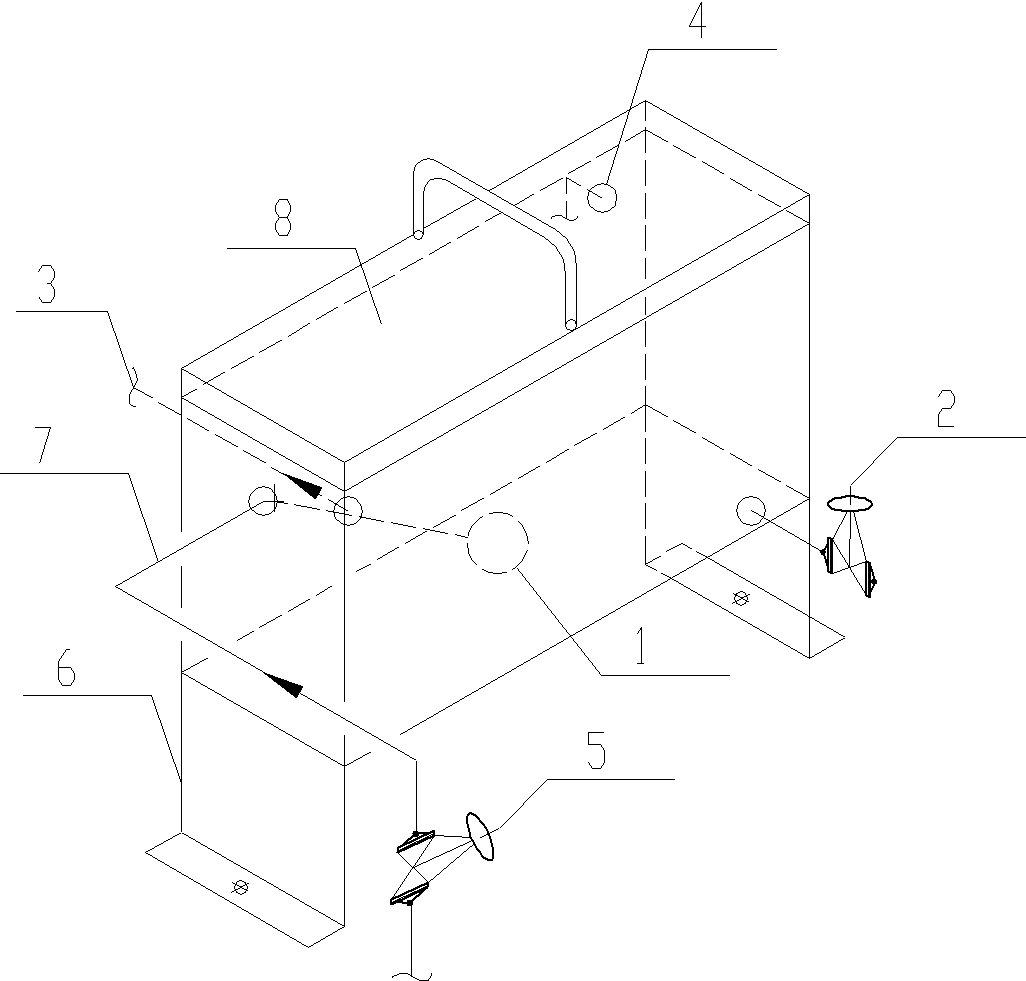

[0018] exist Figure 1-2 In the shown first embodiment of the oil injection device of the ketone-benzene drum filter of the present invention, the oil injection device includes an oil injector 9 installed on a base 10 . Due to the limited internal space of the existing oil injector, there is not enough space to accommodate the liquid level control device. Therefore, the present invention cleverly arranges an automatic oil replenisher for filling oil into the oil injector 9 outside the oil injector 9, and the automatic oil replenisher includes an oil tank 11 and a liquid level control device. The oil tank 11 is assembled on the bracket 6 .

[0019] The oil tank 11 communicates with the oil injector 9 to form a connector, and the oil level in the oil tank 11 and the oil injector 9 is the same. The control of the oil level in the oil injector 9 can be realized by adjusting the oil level in the oil tank 11 through the liquid level control device. In addition, the additional oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com