PDAF function detection machine for camera modules and detection method of PDAF function detection machine

A camera module and functional testing machine technology, applied in photography, optics, instruments, etc., can solve the problems of low testing efficiency, inability to meet industrial needs, complex testing structure of testing machines, etc., to achieve high testing efficiency, high degree of automation, Check for full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

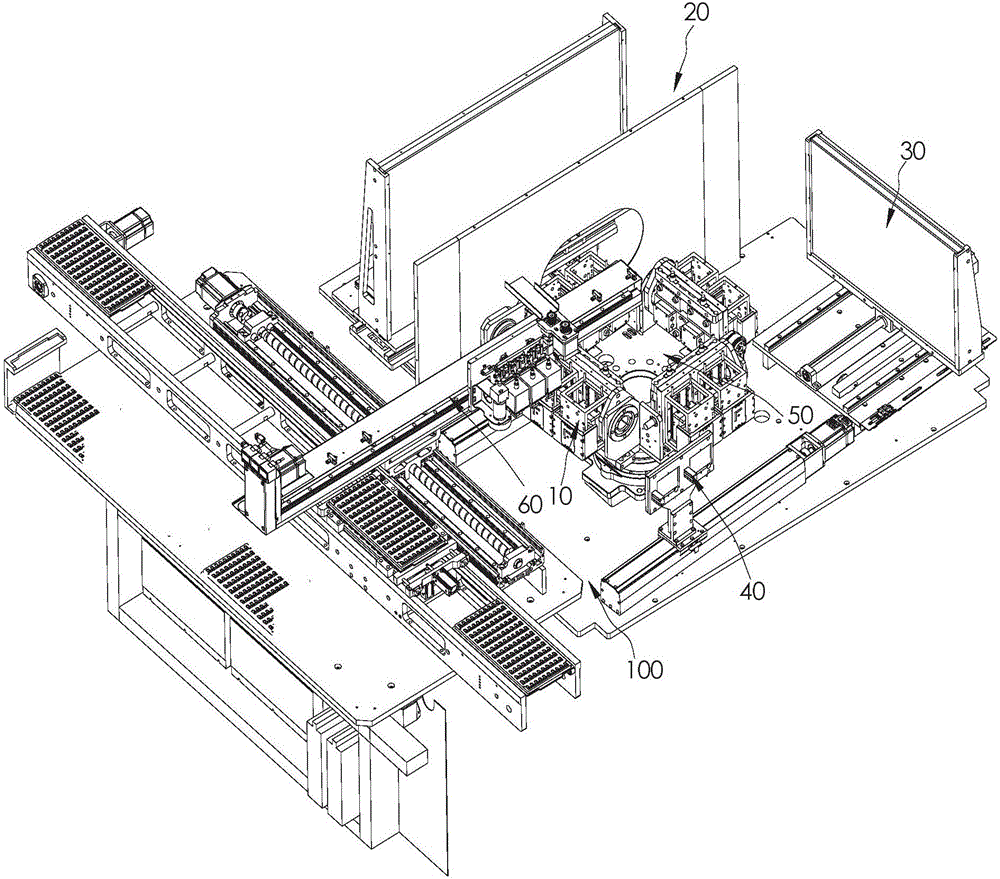

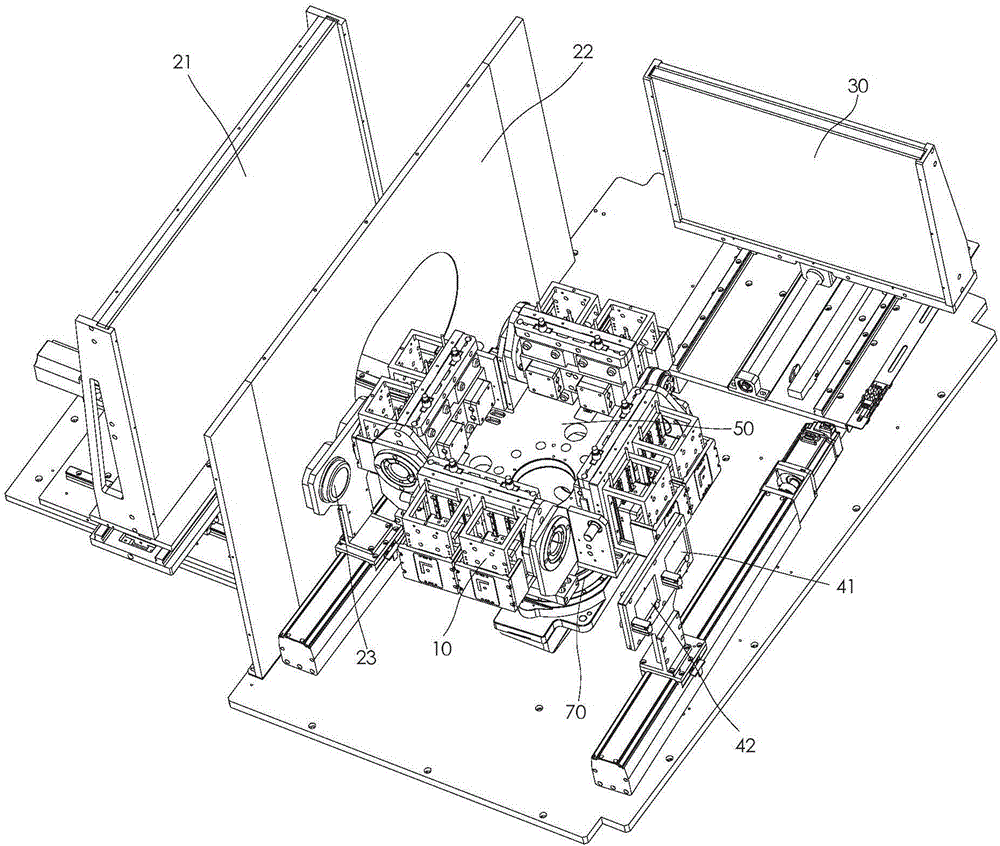

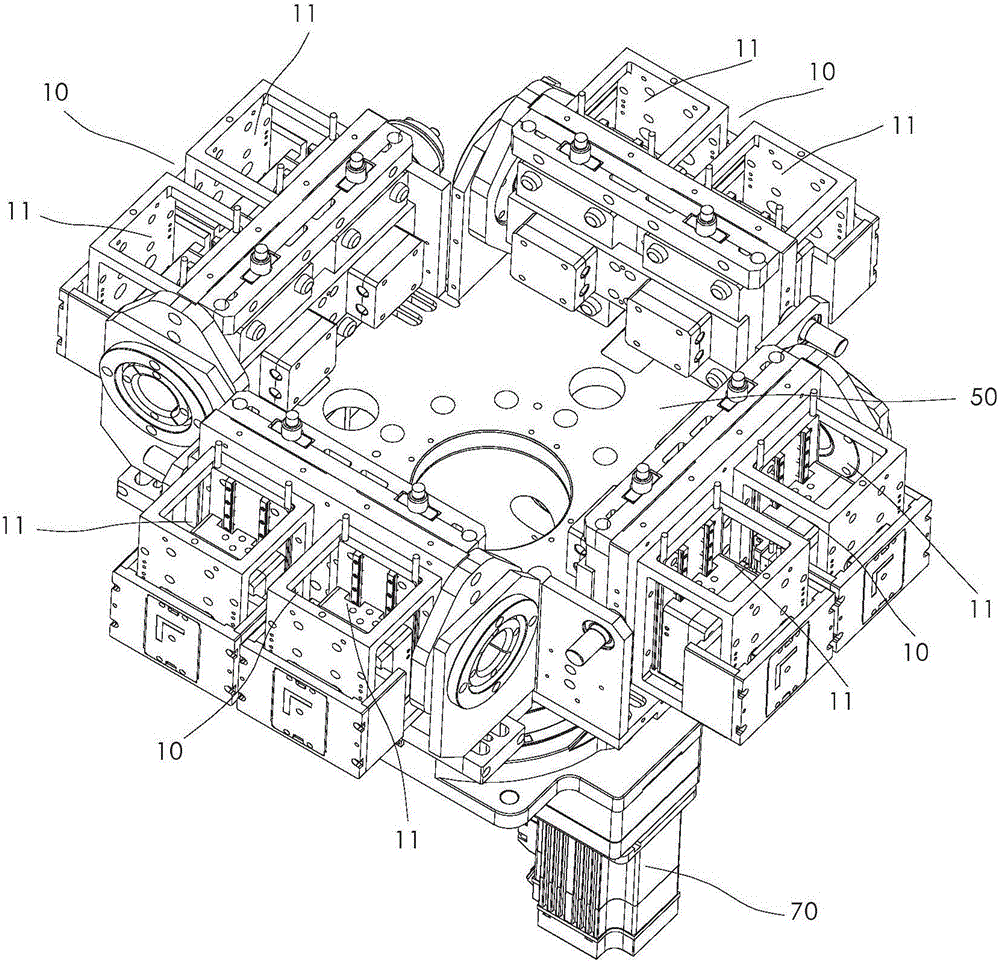

[0031] Such as Figure 1-4 The shown camera module PDAF function testing machine includes a body 100 and a conveying mechanism installed on the body 100 . The body 100 is provided with a plurality of detection stations 10, a long-range detection mechanism 20, a close-up detection mechanism 30, and a black-and-white field detection mechanism 40. The above-mentioned multiple detection stations 10 can be transported along a first conveying mechanism under the drive of the above-mentioned conveying mechanism. The directions are cyclically and staggered and sent to the distant view detection mechanism 20 , the close view detection mechanism 30 , and the black and white field detection mechanism 40 in sequence.

[0032] On the basis of the above structure, when using the camera module PDAF function detection machine of the present invention, a feeding statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com