Sealing device and method suitable for ultra-high pressure strengthened wood

A sealing device and ultra-high pressure technology, applied in the direction of wood compression, etc., can solve the problems of puncture and strengthening failure of film packaging bags, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

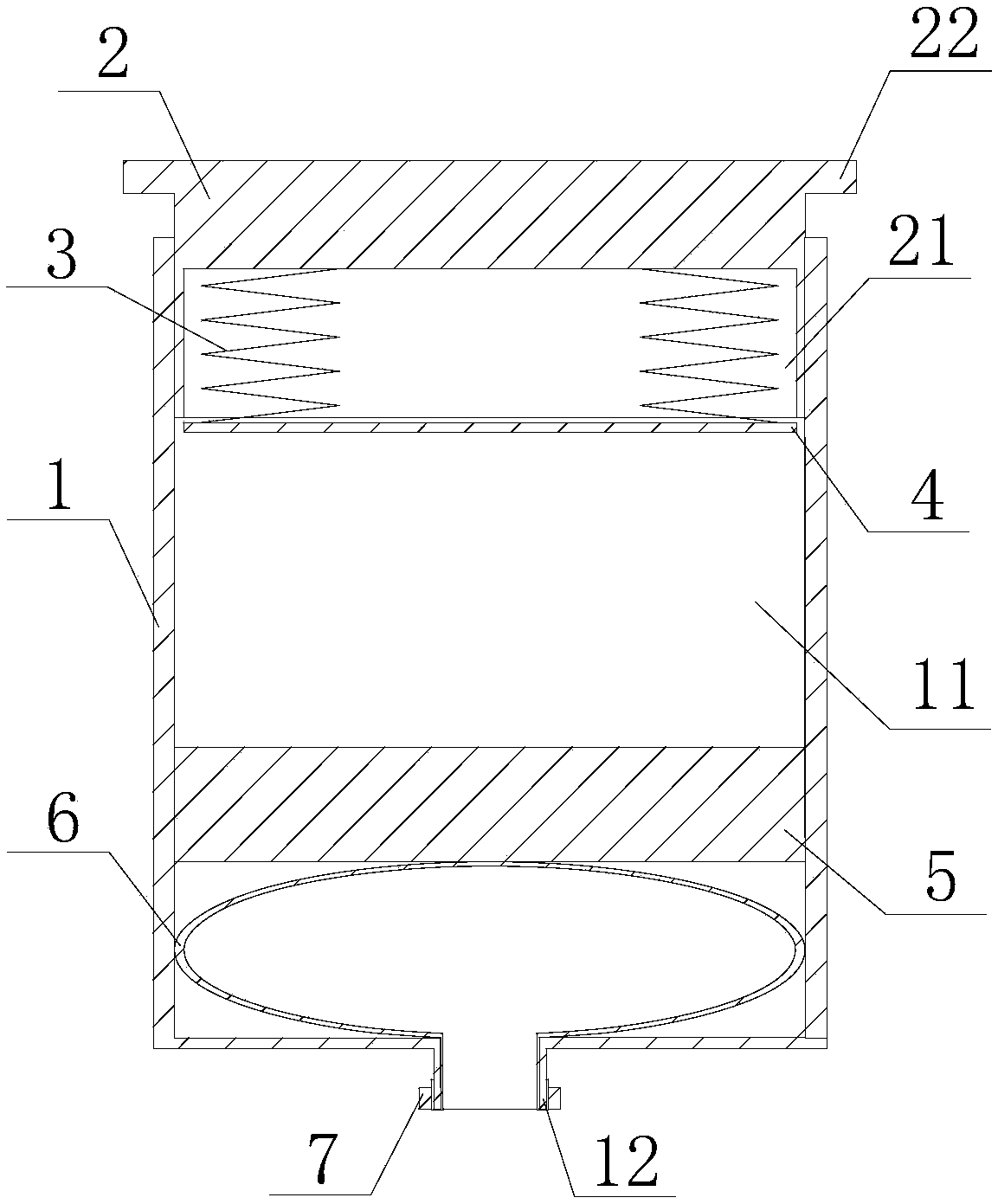

[0030] Embodiment 1, a kind of sealing device that is suitable for ultra-high pressure strengthened wood, such as Figure 1~2 As shown, it includes a hollow cavity 1 and a gland 2, the top of the cavity 1 is open, and the inner wall at the top opening of the cavity 1 is provided with internal threads. The outer wall of the gland 2 is provided with an external thread that matches the internal thread of the cavity 1, and a sealing ring is provided between the cavity 1 and the gland 2; the gland 2 can be screwed into the top opening of the cavity 1 , thereby sealing the inner cavity 11 of the cavity 1 . A groove 21 is provided at the bottom of the gland 2 . A horizontal plate 4 , a piston 5 and an expansion pressure bag 6 are sequentially arranged in the inner cavity 11 of the cavity 1 from top to bottom.

[0031] Two identical springs 3 are arranged symmetrically in the groove 21, that is, the elastic coefficient and the number of turns of the two springs 3 are all the same; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com