Pipeline winding device used in plastic pipe production workshop

A technology for producing workshops and plastic pipes, which is applied in thin material handling, transportation and packaging, and transportation of filamentous materials, etc., can solve the problems of workshop environment and job impact, and achieve the effect of improving stranding efficiency and tidy environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

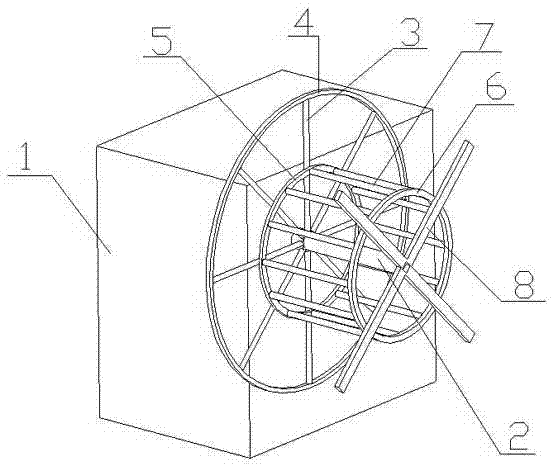

[0007] like figure 1 As shown, the present invention consists of a motor box 1, a motor, a central axis 2, a set of inner gear rods 3, a reinforcement ring 4, an inner twisted coil 5, an outer coil 6, a set of twisted wire rods 7 and a set of outer gear rods 8 , the motor is installed in the motor box 1, one end of the central shaft 2 is connected to the power output shaft of the motor, one end of a set of inner gear rods 3 is connected to the central shaft 2, and the central shaft 2 is evenly arranged on the central shaft 2, the reinforcing ring 4 is connected with the other end of a group of inner gear rods 3, the inner twisted coil 5 is installed on a group of inner gear rods 3, one end of a group of outer gear rods 8 is connected with the other end of the central shaft 2, and the external coil 6 is installed on a group of outer gear rods 8, and the two ends of a group of twisted wire rods 7 are respectively connected to the inner twisted coil 5 and the outer coil 6.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com