Multi-face external pressing type fast energy-saving conductive connector

A conductive joint, external pressure technology, applied in the direction of conductive connection, circuit, connection, etc., can solve the problems of complicated installation, the wire can not be put into use again, easy to break, etc., to achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

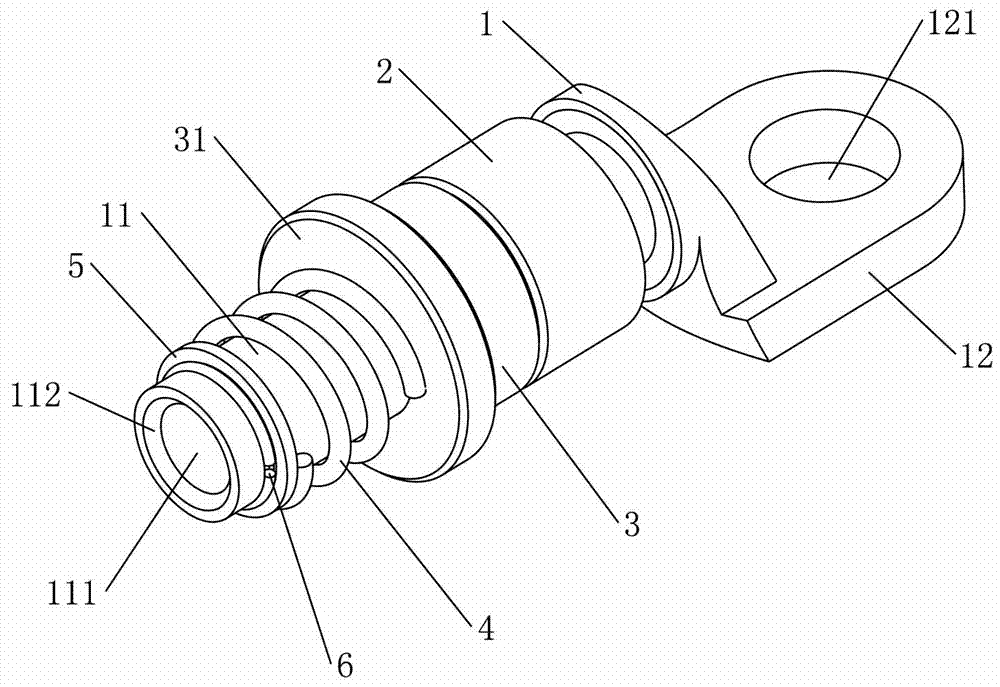

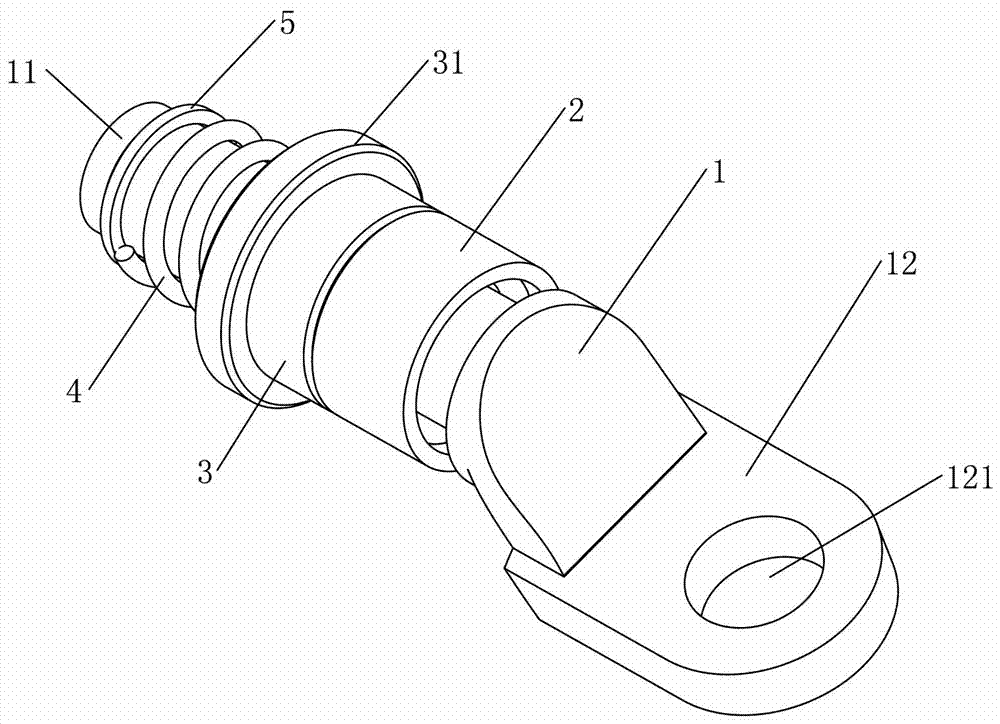

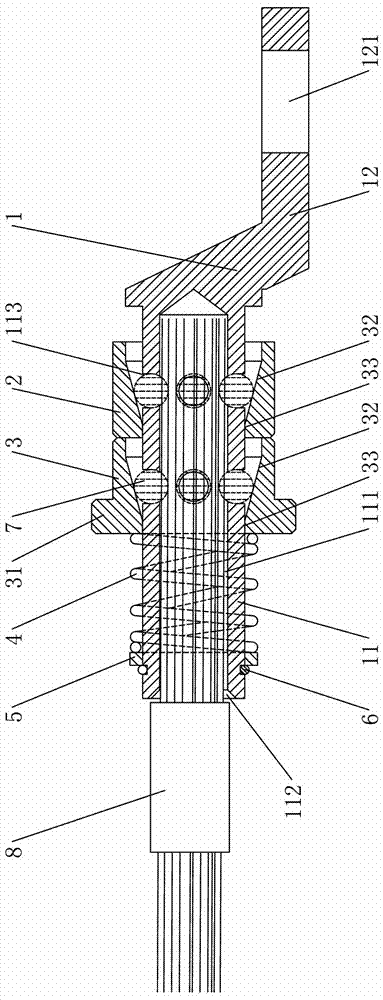

[0024] Embodiment one, see Figure 1 to Figure 3 As shown, a multi-faceted external pressure fast energy-saving conductive joint includes a conductive joint body 1, the conductive joint body 1 is provided with a sleeve 11, and the sleeve 11 is provided with a threading hole 111, and the threading hole 111 is connected to the outside of the sleeve 11. Connected; the sleeve 11 is provided with an external wire locking device corresponding to the threading hole 111, and the external wire locking device extends from the outside to the inside of the threading hole 111. The top ring and the elastic member used to push the top ring. The outer circumference of the sleeve 11 is provided with a through hole 113 corresponding to the crimping top 7. The through hole 113 communicates with the threading hole 111. The top ring is sleeved on the outer circumference of the sleeve 11 and along the The axial direction of the sleeve 11 is slidably matched, and the top ring is pushed and fitted wi...

Embodiment 2

[0031] Embodiment two, the difference with embodiment one is: see Figure 4 As shown, the conductive connector body 1 is provided with two sleeves 11 , and the two sleeves 11 are respectively located at two ends of the conductive connector body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com