A backside observation base for positioning in chip failure analysis and using method

A failure analysis and positioning method technology, which is applied in the direction of instruments, measuring devices, electronic circuit testing, etc., can solve problems such as troublesome analysis work and difficult precise positioning, and achieve the effect of accurate conversion, positioning speed and accuracy rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

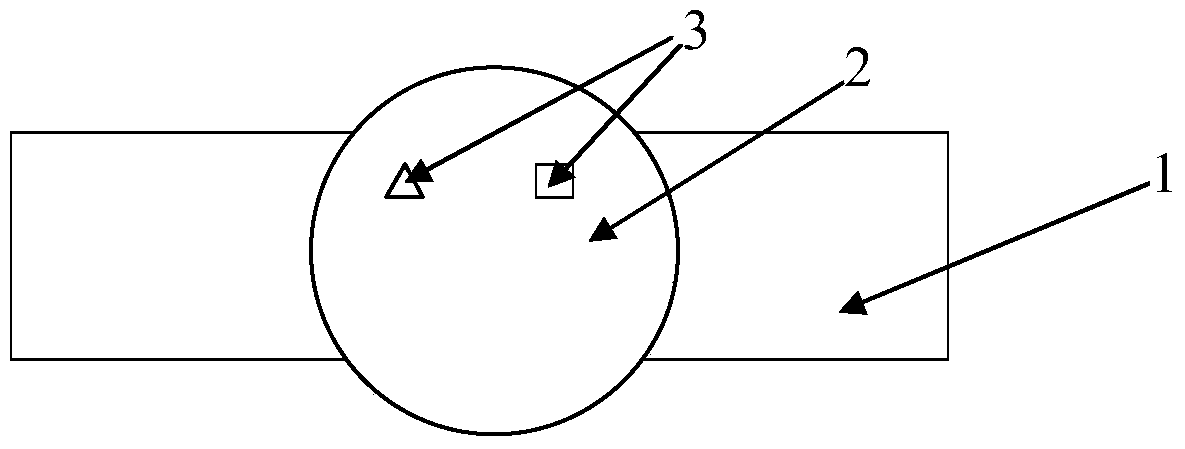

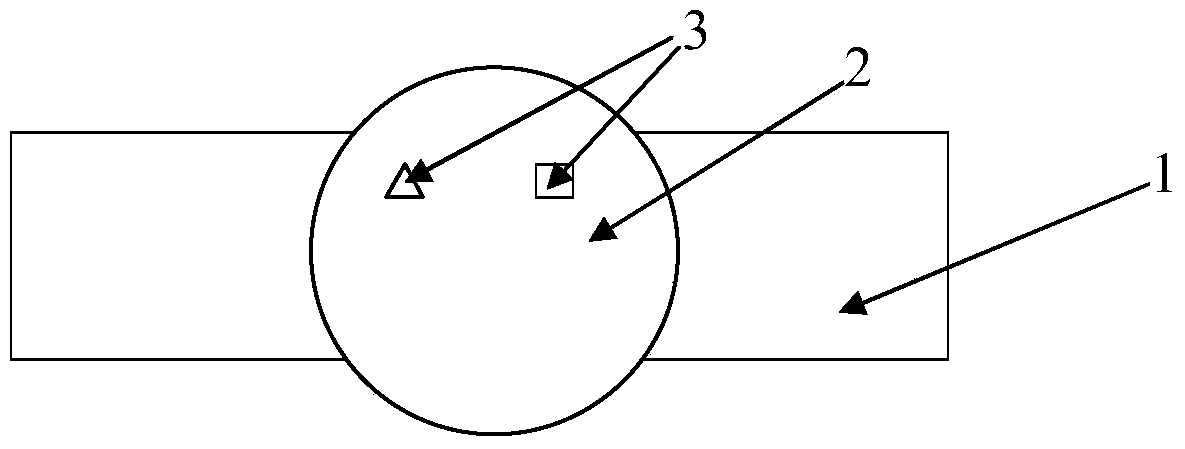

[0025] Such as figure 1 As shown, the rear viewing base used for accurate positioning in chip failure analysis of the present invention includes a metal support 1 , a central hole is provided in the center of the metal support 1 , and a glass plate 2 is installed in the central hole. Two special marks 3 of a triangle and a rectangle for providing reference coordinates have been etched on the glass sheet 2, any one of these two special marks 3 can be set as mark point A, and the other can be set as mark point B . In addition, the special mark 3 may be etched before the analysis, or temporarily pasted on the glass slide 2 during the analysis. The metal support 1 of the rear viewing base can be any metal material with a certain strength and can bear a certain load. Since the weight of the wafer carried is very small, its material is not particularly limited, but considering the economical properties and strength, it is preferably stainless steel.

[0026] The glass sheet 2 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com