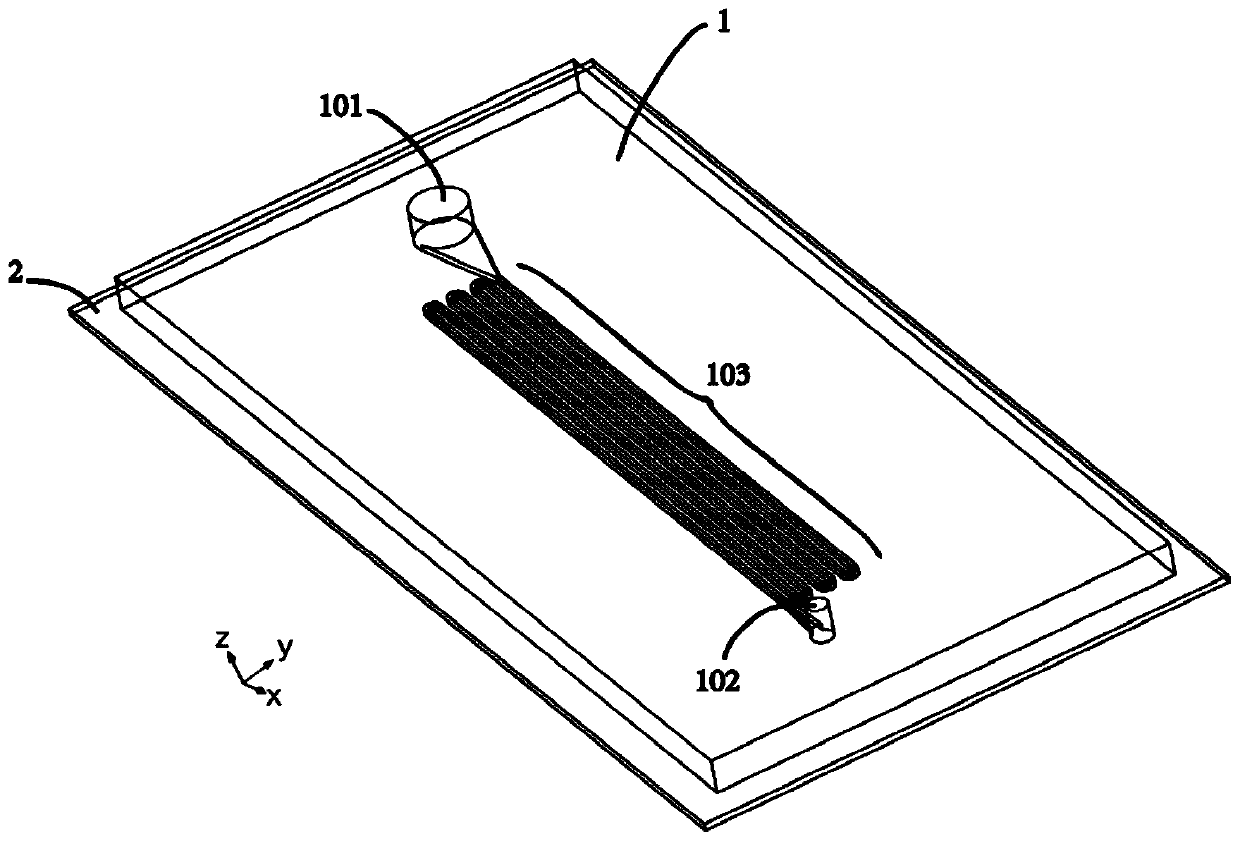

A sheath-free particle three-dimensional focusing microfluidic chip and its focusing method

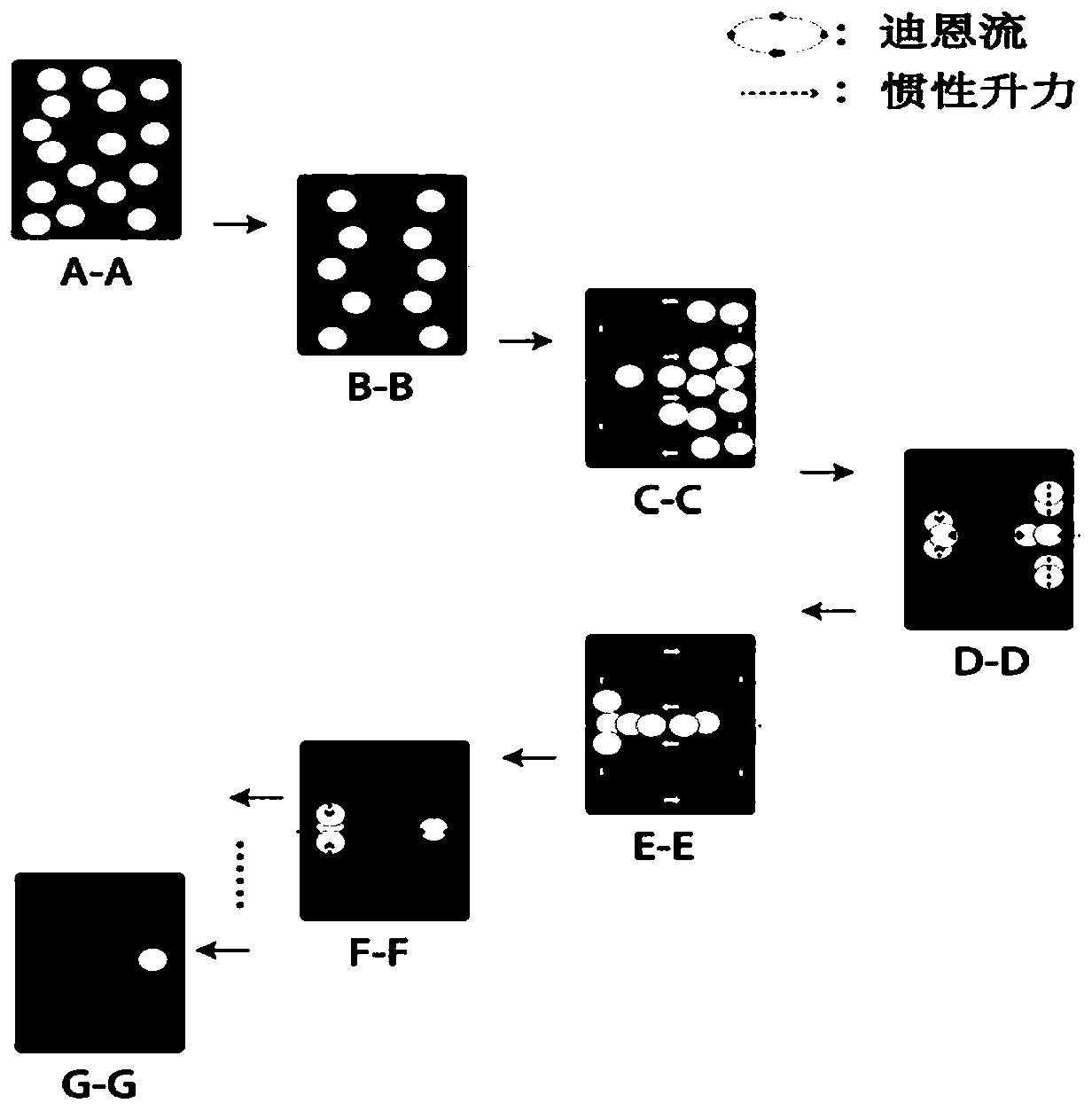

A microfluidic chip, focusing method technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., to achieve high-precision single-beam focusing, reduce stirring effects, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

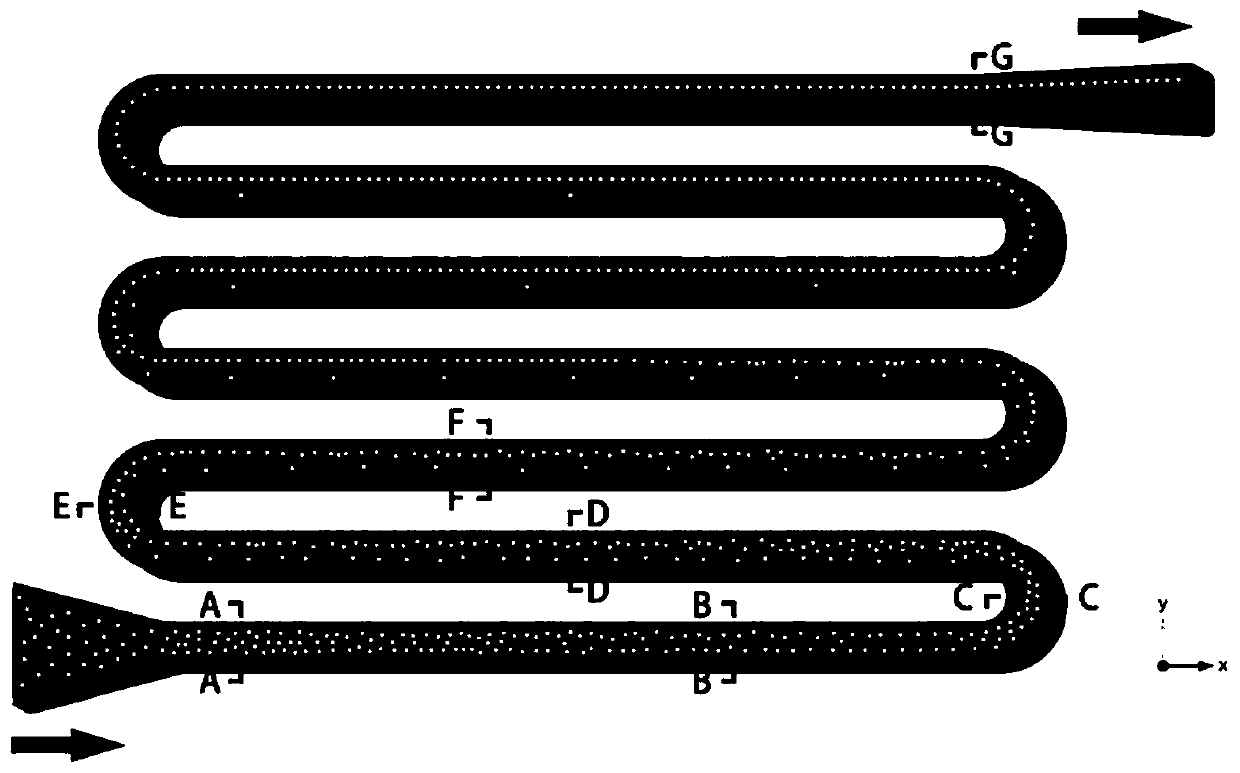

[0028] Embodiment: In a specific embodiment, the channel structure designed in the present invention can realize single-beam focusing on particle samples. B6-F10 black tumor particles and HeLa particle samples were diluted to 10000 / ml with PBS buffer (Thermo Fisher Scientific, MA, USA). Before passing the particle sample, pass PBS buffer solution into the flow channel to wash for 30 minutes. Afterwards, B6-F10 black tumor particles, HeLa particle suspensions, and polystyrene (PS) rigid balls with particle sizes of 7.32 μm, 10.4 μm, and 15.45 μm were passed into the flow channel at a flow rate of 0.8 ml / min for comparison. experiment. The flow channel has been washed with PBS buffer for 30 min before the particles are introduced. A MicroVision industrial camera was used to take continuous pictures of the outlet flow channel, and the exposure time was set to 10us. The 60 bright-field photos were superimposed using ImageJ software. The experimental results show that under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com