Automatic water injecting and discharging counter weight tanks for gates

A technology for water supply and drainage and drainage valves, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of increasing the cost of gates and hoists, increasing the closing force of gates, increasing the opening force of gates, etc., to achieve saving The cost of the counterweight, the reduction of the opening force of the gate, and the effect of remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

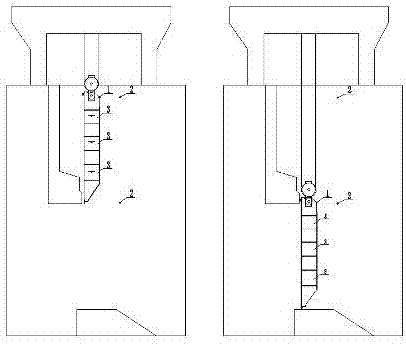

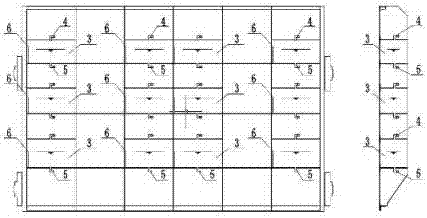

[0008] Automatic water supply and drainage counterweight water tank 3 of the present invention, as figure 1 As shown, including height sensor 1, height indicator 2 and water tank 3; figure 2 As shown, the water tank 3 is evenly distributed between the main girders on the downstream side of the gate body. The top of the water tank 3 is provided with a water supply valve 4, and the bottom is provided with a drain valve 5. The valves are all automatic induction switches. The opening of the valves is controlled by the height sensor 1. The closing of valve is controlled by the water level sensor 6 in the water tank 3.

[0009] The automatic water supply and drainage counterweight water tank 3 of the present invention: as figure 2 As shown, the body of the water tank 3 is welded by steel plates. The volume of the water tank is determined according to the calculated weight. The height and width of the tank are the same as the distance between the main beams, and the thickness is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com