Passive gate bottom-edge device with function of automatic adjustment of water column pressure

An automatic adjustment, water column pressure technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve problems such as high cost and large opening and closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

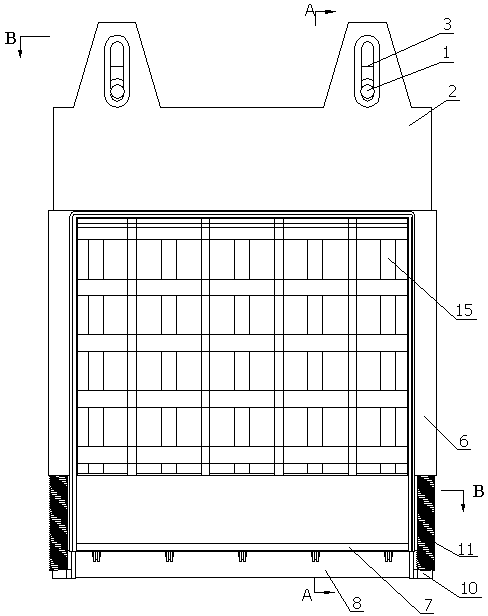

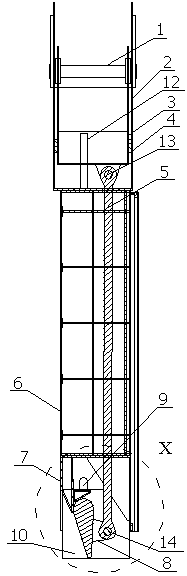

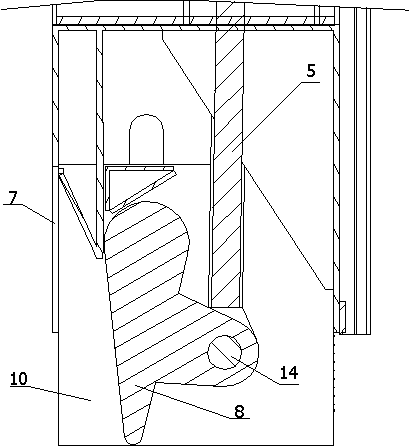

[0027] Such as figure 1 , 2 , 3, a passive automatic adjustment water column pressure gate bottom edge device, including lifting shaft 1, outer box 2, inner box 3, middle water stop 4, connecting rod 5, door leaf 6, bottom edge frame 7 and bottom edge Rotating mechanism 8; the inner box 3 is set in the outer box 2, the inner wall of the outer box 2 is provided with a chute matching the inner box 3, the lifting shaft 1 is installed on the top of the inner box 3, and the middle stop The water 4 is arranged between the outer box 2 and the inner box 3 to isolate the inner cavity of the outer box 2 from the outside world; the outer box 2 is equipped with a positioning device 12, and the positioning device 12 cooperates with the inner box 3; the top of the door leaf 6 It is fixedly connected with the outer box 2, the bottom of the door leaf 6 is fixedly connected with the bottom edge frame 7, the fixed side of the bottom edge rotating mechanism 8 is hinged on the bottom edge frame ...

Embodiment 2

[0034] Such as Figure 5 As shown, a passive automatic adjustment water column pressure gate bottom edge device, the difference between embodiment 2 and embodiment 1 is that this embodiment is applied to the transformation of old gates, so the door leaf 6 cannot be changed, and the connecting rod 5 has a total A pair is arranged symmetrically on the outside of the door leaf 6 .

Embodiment 3

[0036] Such as Figure 6 , 7 , 8, a passive automatic adjustment water column pressure gate bottom edge device, the difference between embodiment 3 and embodiment 1 is that there is no bottom edge bracket 10 in this embodiment, and the bottom edge rotating mechanism 8 is formed by the upper frame 81. The lower frame 82 and the elastic mechanism 11 are formed. The upper frame 81 and the lower frame 82 are connected by the elastic mechanism 11. The upper frame 81 and the lower frame 82 form a moving pair. The upper frame 81 is hinged to the bottom edge frame through a hinge shaft. 7, the lower frame 82 is hinged with the connecting rod 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com