Inserting and dismounting type ventilation window

A ventilation window and screen window technology, which is applied to windows/doors, door/window protection devices, insect protection, etc., can solve the problems of inconvenient cleaning, reduced service life of transformers, and large load loss, etc., and achieves convenient cleaning, reliable installation, and quick disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

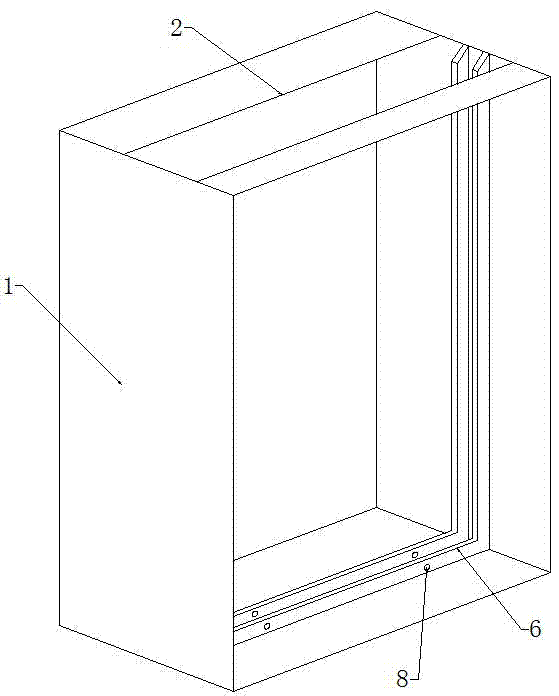

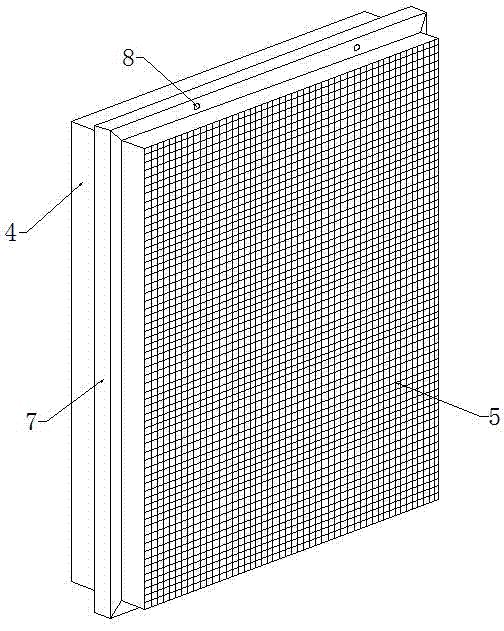

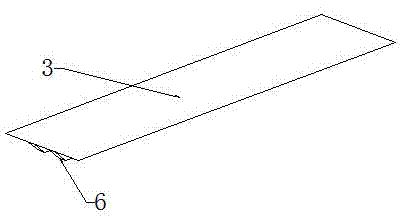

[0015] A detachable ventilation window, comprising a frame 1 and a screen window 4, the top of the frame 1 is provided with an opening 2, the opening 2 is provided with a cover plate 3, and the inside of the frame 1 and the lower end of the cover plate 3 are respectively provided with Clamping groove 6 is used to block the protruding strip 7 to prevent the screen window 4 from moving easily, etc. The outside of the screen window 4 is provided with a dust-proof net 5 to prevent dust such as dust from entering the equipment room, and the screen window 4 is provided with protruding strips 7 around , for installation in the clamping groove 6, the convex strip 7 is matched with the clamping groove 6, the clamping groove 6 at the bottom of the frame 1, the clamping groove 6 on the cover plate 3 and the convex strips 7 at the upper and lower ends of the screen window 4 Screw holes 8 are respectively provided for fixing the screen window 4 and the cover plate 3 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com