Coffee brewing machine

A brewing machine and coffee technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of coffee machine 1 with complex structure, hot water outflow, high production cost, etc., and achieve the effect of improving smoothness and use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

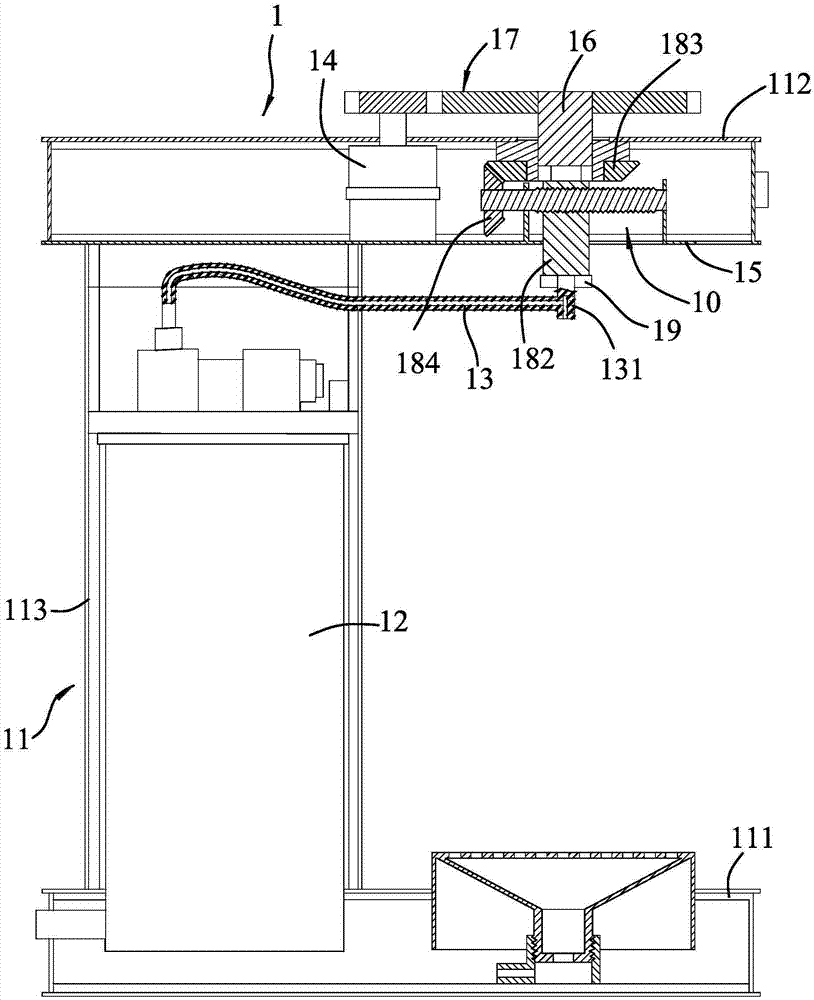

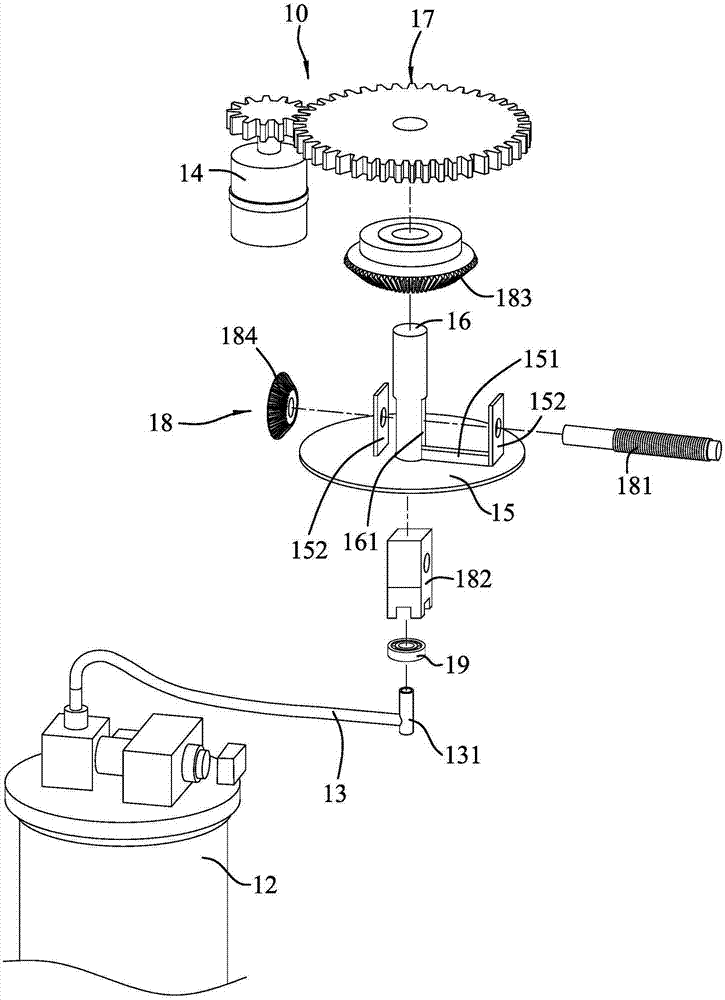

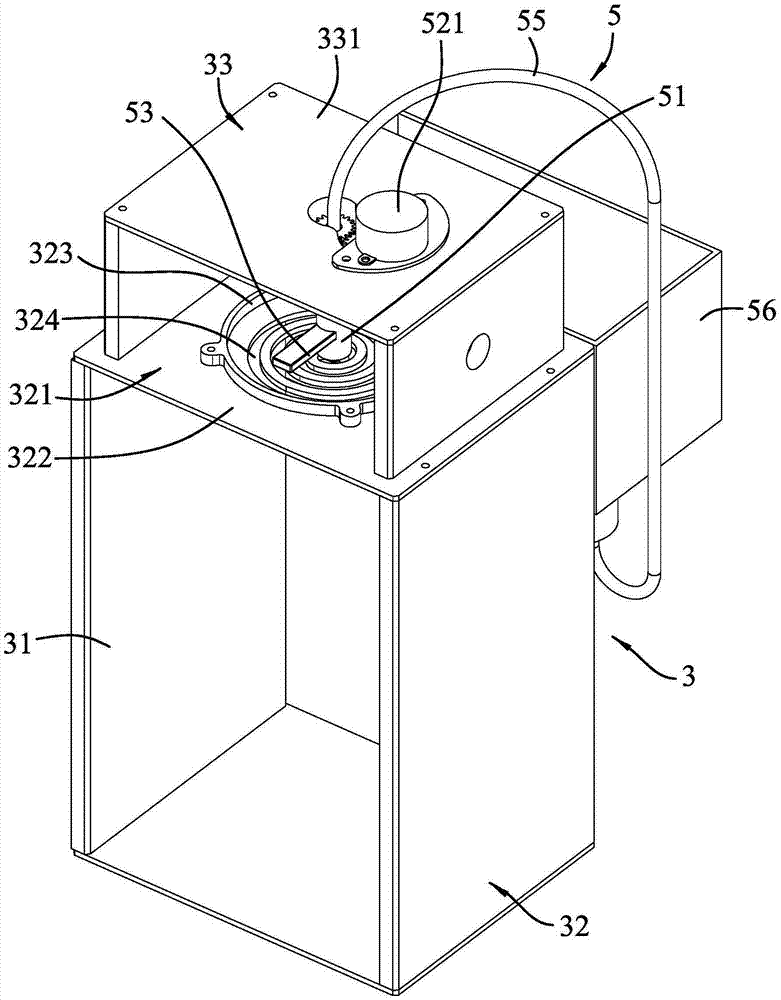

[0033] refer to image 3 , 4 5. A first embodiment of the coffee brewing machine of the present invention is suitable for brewing ground coffee powder. The coffee powder is usually placed inside a filter cup 21, and the brewed and filtered coffee liquid flows into In a coffee pot 22 below. The coffee brewing machine includes: a base frame 3 for placing the filter cup 21 and the coffee pot 22 , and a water supply mechanism 5 installed on the base frame 3 and supplying hot water for brewing ground coffee. The base frame 3 includes a lower frame seat 32 defining a placement space 31, and an upper frame seat 33 lapped above the lower frame seat 32. The lower frame seat 32 has a water outlet guide located above and horizontally wall 321, the water outlet guide wall 321 has a rectangular main wall portion 322, a frame surrounding portion 323 protruding u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap