A vacuum suction blank structure and a feeding mechanism comprising the vacuum suction blank structure

A feeding mechanism and vacuum suction technology, applied in the field of feeding mechanism and vacuum suction blank structure, can solve the problems of rough texture, pattern damage, limited surface pattern, etc., to achieve smooth conveying process, improve production efficiency, and reduce pressing effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

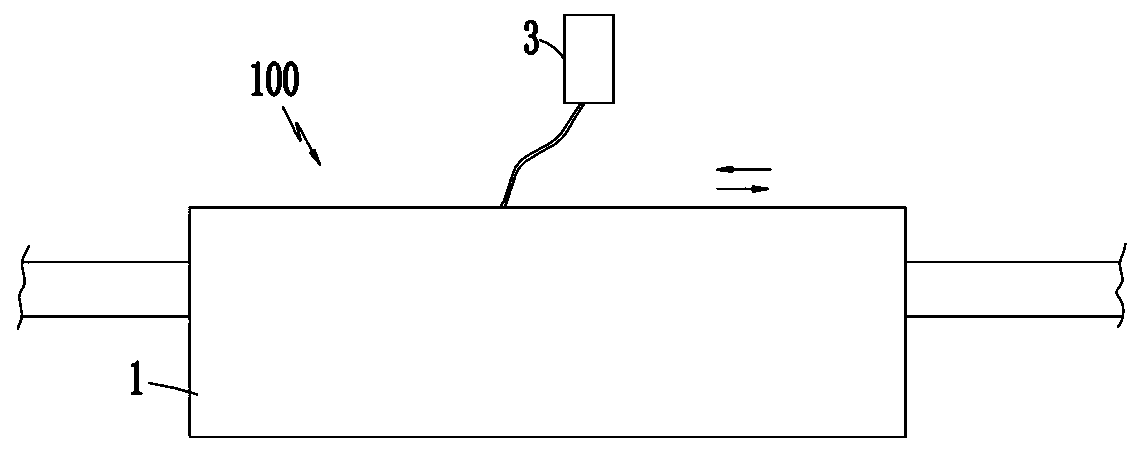

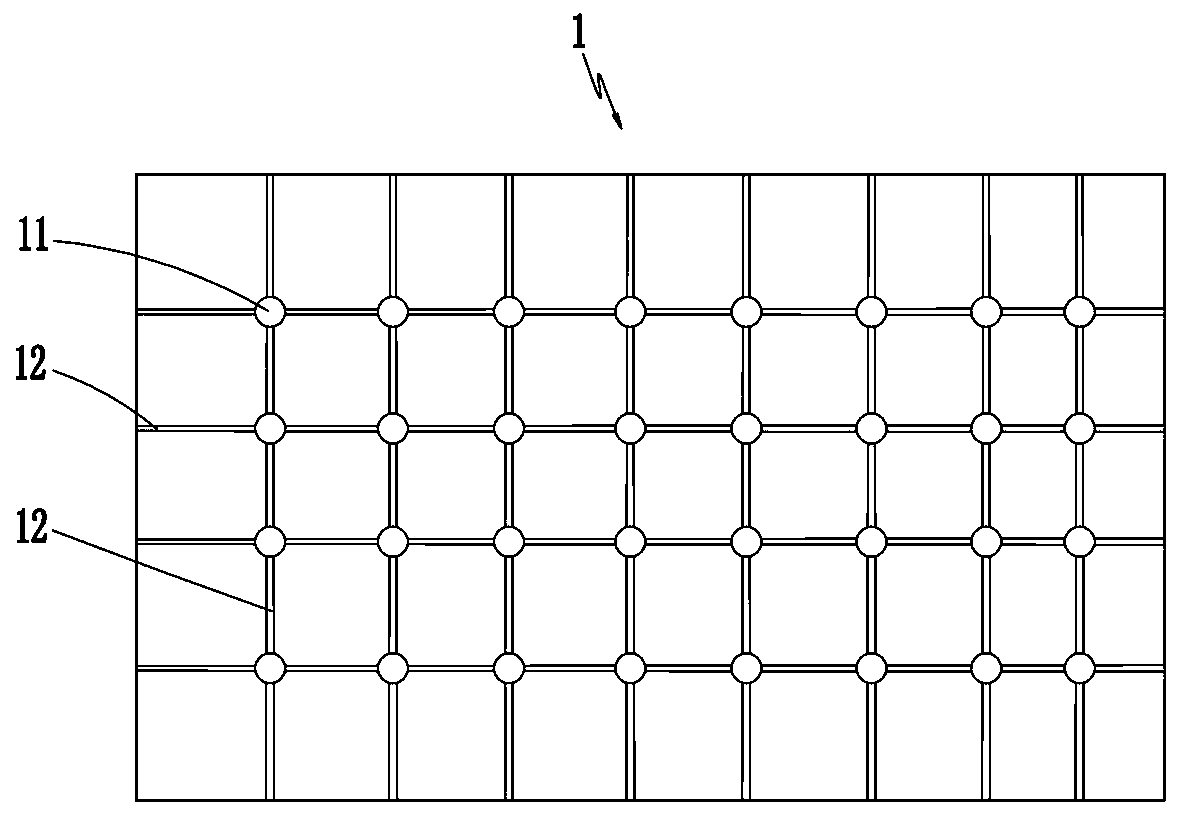

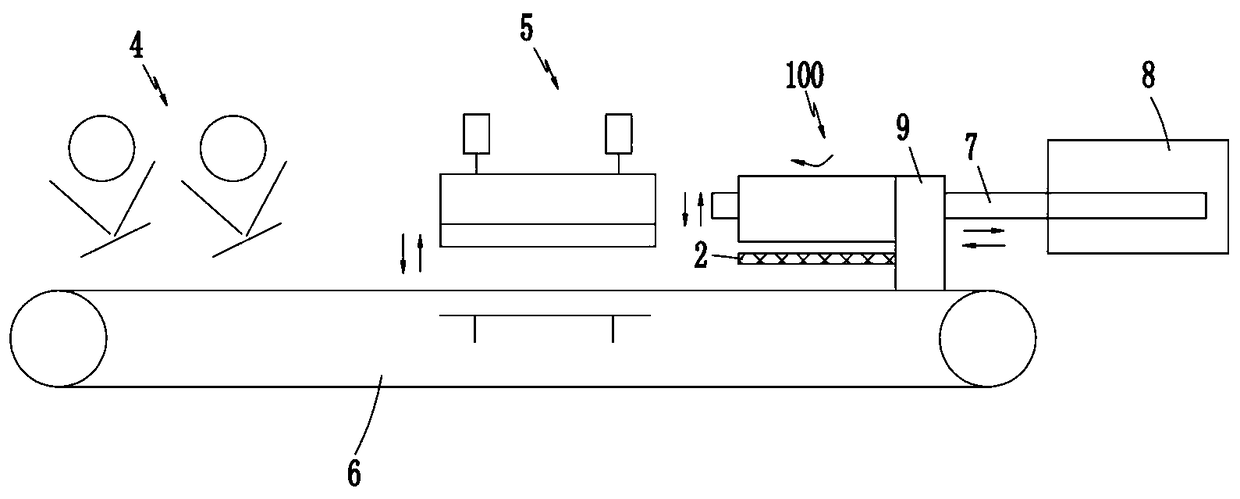

[0016] See attached figure 1 and 2 As shown, this embodiment provides a vacuum suction blank structure 100, which includes a vacuum suction mold 1 for absorbing ceramic tiles, a lifting drive cylinder (not shown in the figure) for driving the vacuum suction mold 1 to move up and down, and The vacuum generating device 3 used to make the vacuum suction mold 1 generate a vacuum air source, wherein the bottom end surface of the vacuum suction mold 1 is provided with a plurality of suction and exhaust grooves 12 arranged in a vertical and horizontal direction, and each pair of intersecting An air hole 11 communicating with the vacuum generating device 3 is provided at the intersection of the suction and exhaust grooves 12 . At the same time, in order to enable the vacuum suction blank structure 100 to drive the ceramic blank to rotate in the horizontal direction, it is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com