Lipase immobilized carrier, immobilized lipase and preparation method and application thereof

A technology of immobilized lipase and lipase, applied in the field of enzyme engineering, can solve the problems of high price and few varieties of immobilized lipase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Preparation of immobilized lipase

[0072] The method of the present invention for preparing an immobilized lipase generally includes the steps of mixing the lipase with seed residue and powdered adsorbent, separating out the solid, and drying the solid.

[0073] It will be appreciated that the seed residue can be mixed with the powdered sorbent prior to mixing the resulting mixture with the lipase. Alternatively, it is also possible to mix the lipase with the seed residue or powdered sorbent first, and then mix the resulting mixture with another carrier (the powdered sorbent or the seed residue).

[0074] The mixing process is the immobilization process. It can be carried out in the manner of immobilization conventional in the art, for example, it can be mixed / immobilized in a mixer. For example, in certain embodiments, mixing is performed on an air bath shaker at 100-200 rpm. The mixing should be such that the lipase and the seed residue and / or powdered sorbent a...

Embodiment 1

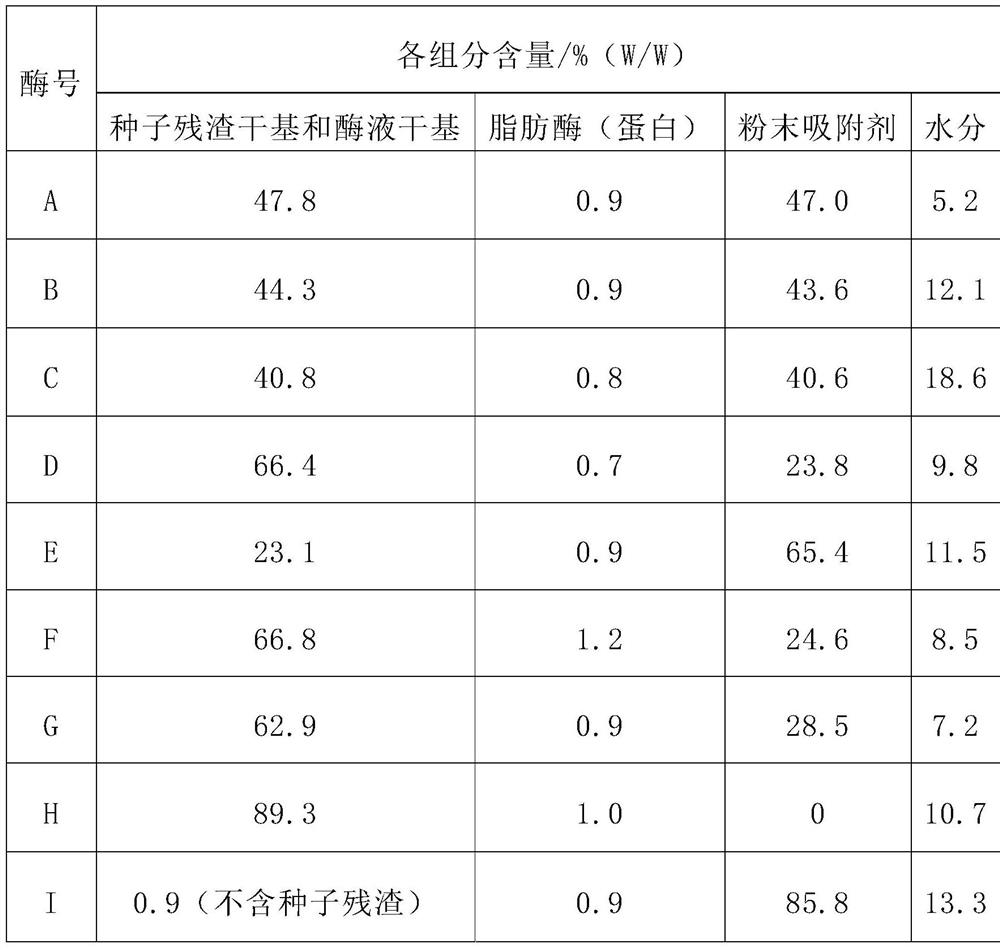

[0099] Example 1: Preparation of immobilized lipase

[0100] 1. Mix 10g corn residue (Shanghai Kerry Food Industry Co., Ltd.) with 10g white carbon black (Hubo Engineering Materials Co., Ltd.), and 150mL self-fermented Thermomyces lanuginosus lipase solution (41700U / mL, measured by olive oil emulsification method) was added into it, the air-bath shaker was 120rpm, fixed at 25°C for 4h, the solid was collected by suction filtration, and the solid was divided into three parts for drying respectively, and the inlet air temperature of the fluidized bed was 40°C, Inlet air volume 0.6m 3 / min, fluidization time 35min, drying to obtain immobilized enzyme A, natural air-drying for 5 days to obtain immobilized enzyme B, and freeze-drying at -20°C for 24 h to obtain immobilized enzyme C.

[0101] 2. Mix 100g of bean dregs (Shanghai Kerry Food Industry Co., Ltd., water content 85%) with 10g of white carbon black (Hubo Engineering Materials Co., Ltd.), and mix the commercially available ...

Embodiment 2

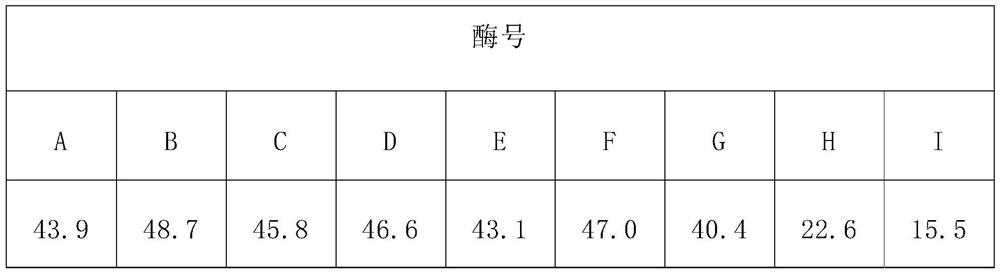

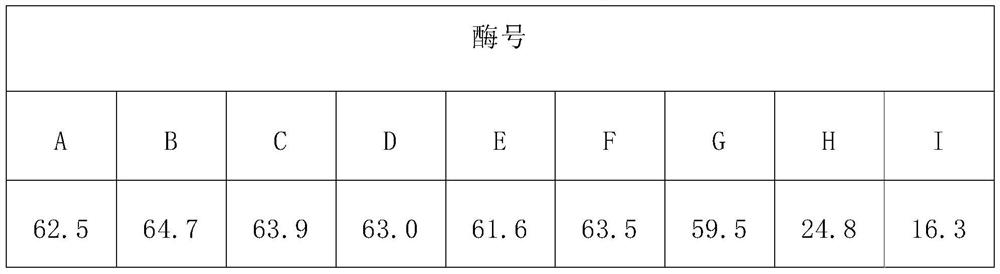

[0111] Example 2: Immobilized lipase hydrolysis activity

[0112] The hydrolysis activity of the immobilized lipase was determined by the olive oil emulsification method, and the specific method was referred to the literature YT Gargouri, et al. Process Biochemistry, 2011. The results are shown in Table 2.

[0113] Table 2: Immobilized lipase hydrolysis activity

[0114] Enzyme number A B C D E F G H I Hydrolysis activity / kU / g 66 113 70 89 57 93 50 10 8

[0115] It can be seen from Table 2 that the immobilized lipase of the present invention has good hydrolysis activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com