Aluminum alloy shell and preparation method thereof

A technology of aluminum alloy and casing, which is applied in the field of aluminum alloy casing and its preparation, and can solve the problems of single decoration and single texture of mobile phone casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the preparation method of the aluminum alloy shell of the present invention, in a preferred situation, different colors can be formed in the oxide film on the convex portion and the oxide film on the concave portion. By forming different colors in the oxide film of the convex part and the oxide film of the concave part, the aluminum alloy shell can have film layers of different colors.

[0029] According to the preparation method of the aluminum alloy shell of the present invention, the preparation method comprises in sequence:

[0030] Step a, performing the first anodic oxidation on the surface of the aluminum alloy shell substrate,

[0031] Step b, performing anti-etching protection on the surface of the aluminum alloy shell substrate to form a protective film,

[0032] Step d, forming a pattern layer on the surface of the aluminum alloy shell substrate with the protective film formed by etching,

[0033] Step e, performing a second anodic oxidation on...

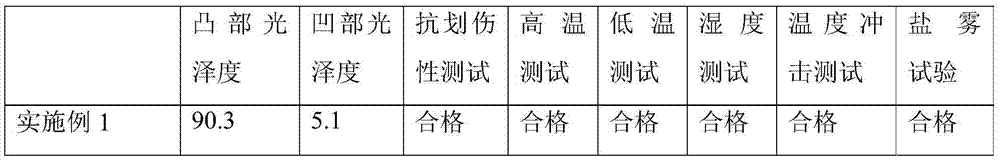

Embodiment 1

[0054] This embodiment is used to illustrate the aluminum alloy shell of the present invention and its preparation method

[0055] A die-casting aluminum alloy back shell base material for a P8 mobile phone (purchased from BYD Co., Ltd.) was used as the aluminum alloy shell base material in this embodiment. At 50°C, the base material of the aluminum alloy shell was etched for 10s in an aqueous solution of sodium hydroxide with a concentration of 55g / L, and then washed twice with deionized water; then, at 15°C, in a concentration of 250ml / L After neutralizing in nitric acid for 10s, wash it twice with deionized water; then, at 90°C, polish it in a chemical polishing solution containing 650ml / L phosphoric acid and 350ml / L sulfuric acid for 10s, then wash it with deionized water for 2 times then, at 15°C, neutralize in 250ml / L nitric acid for 10s, and then wash twice with deionized water; Aluminum alloy shell base material.

[0056] An anodic film is formed on the surface of th...

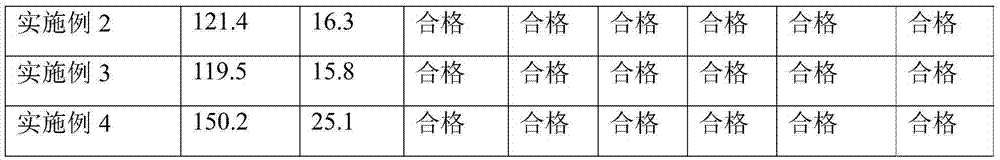

Embodiment 2

[0067] This embodiment is used to illustrate the aluminum alloy shell of the present invention and its preparation method

[0068] A die-casting aluminum alloy back shell base material for a P8 mobile phone (purchased from BYD Co., Ltd.) was used as the aluminum alloy shell base material in this embodiment. At 70°C, the base material of the aluminum alloy shell was etched for 20s in an aqueous solution of sodium hydroxide with a concentration of 60g / L, and then washed twice with deionized water; then, at 20°C, at a concentration of 300ml / L After neutralizing in nitric acid for 20s, wash it twice with deionized water; then, at 93°C, polish it in a polishing solution containing 700ml / L phosphoric acid and 300ml / L sulfuric acid for 10s, then wash it with deionized water for 2 then, at 20°C, neutralize in 300ml / L nitric acid for 20s, and then wash twice with deionized water; Aluminum alloy shell base material.

[0069] An anodic film is formed on the surface of the aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com