Special detection equipment for large shells

A technology for testing equipment and shells, applied in the field of special testing equipment for large shells, can solve the problems of inconvenient mobile transportation and positioning and installation, increase the workload of staff, and prone to errors, so as to improve the flexibility of use and reduce the measurement Difficulty and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

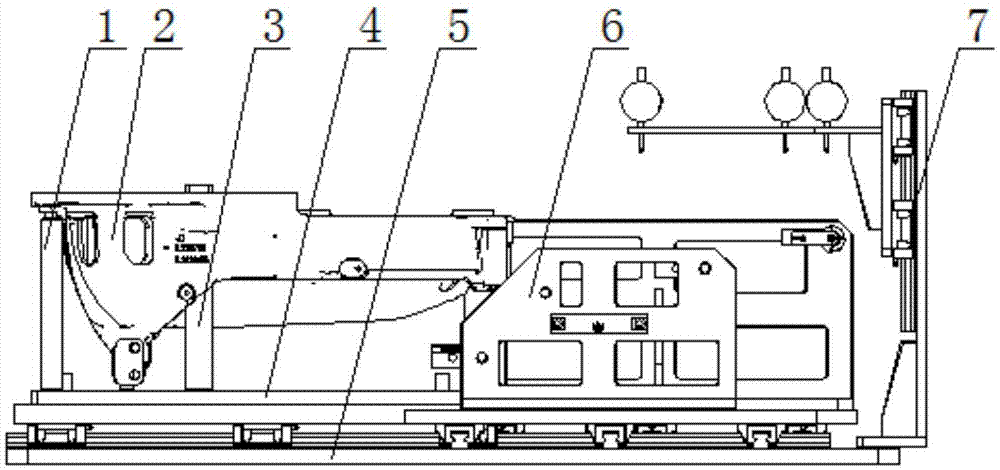

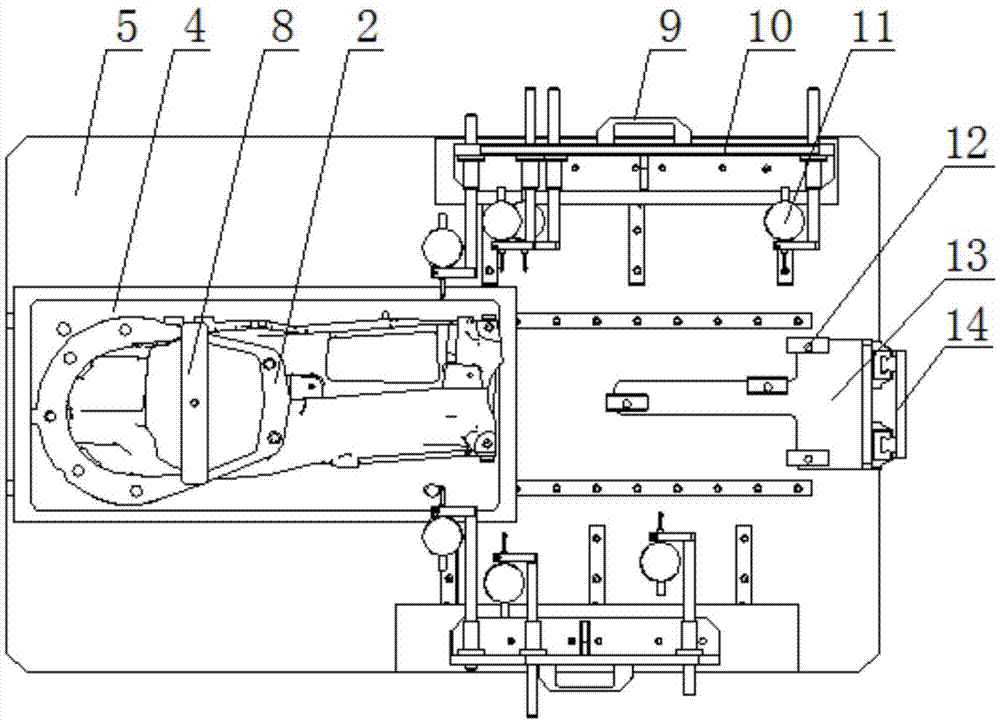

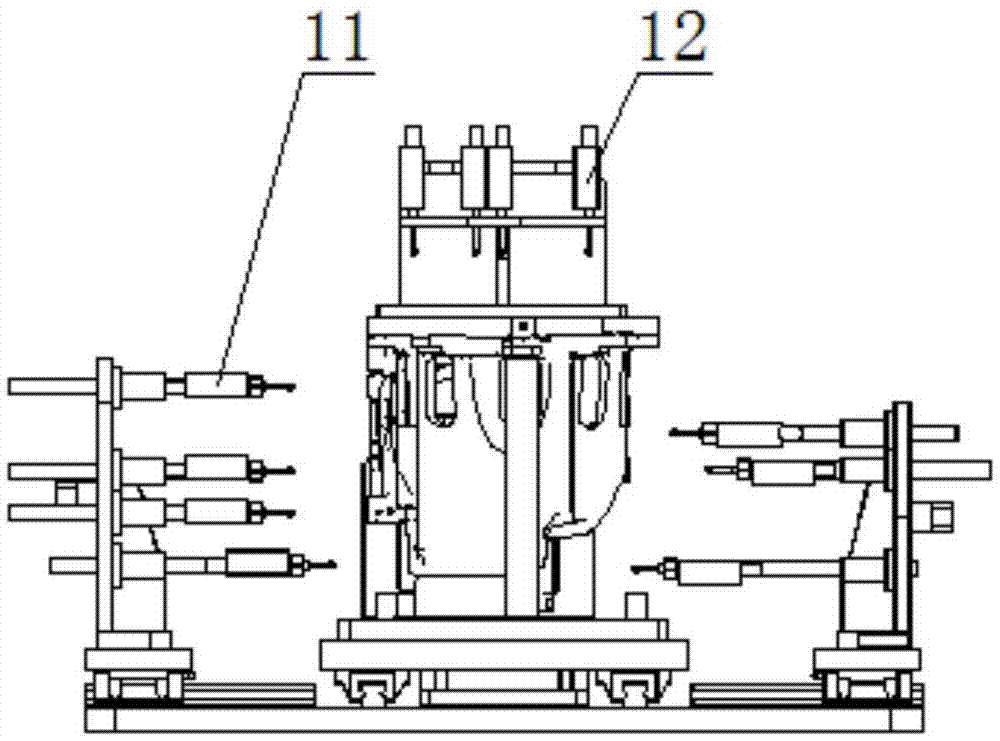

[0020] A special detection device for a large shell, including a main board 5, a workpiece sliding platform 4, a longitudinal movement detection mechanism 6 and a vertical lifting detection mechanism 7, a guide rail is installed on the upper surface of the main board, and the workpiece sliding platform is installed on the guide rail. Positioning stoppers are installed on the main board. A vertical workpiece front-end positioning frame 15 is installed on the front end of the workpiece sliding platform, and a vertical positioning rod 3 is installed on the middle rear part of the workpiece sliding platform. A horizontal pressing plate 8 is installed on the positioning rod, and the rear end of the workpiece sliding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com