A Curve Plotter Used for Processing Special-shaped Workpieces

A special-shaped workpiece and a plotter technology, which is applied in the field of plotters, can solve the problems of low efficiency, inability to draw special-shaped workpieces, and the inability of the plotter to copy, enlarge or reduce the special-shaped workpieces well, and achieve the effect of high efficiency, fast and accurate efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

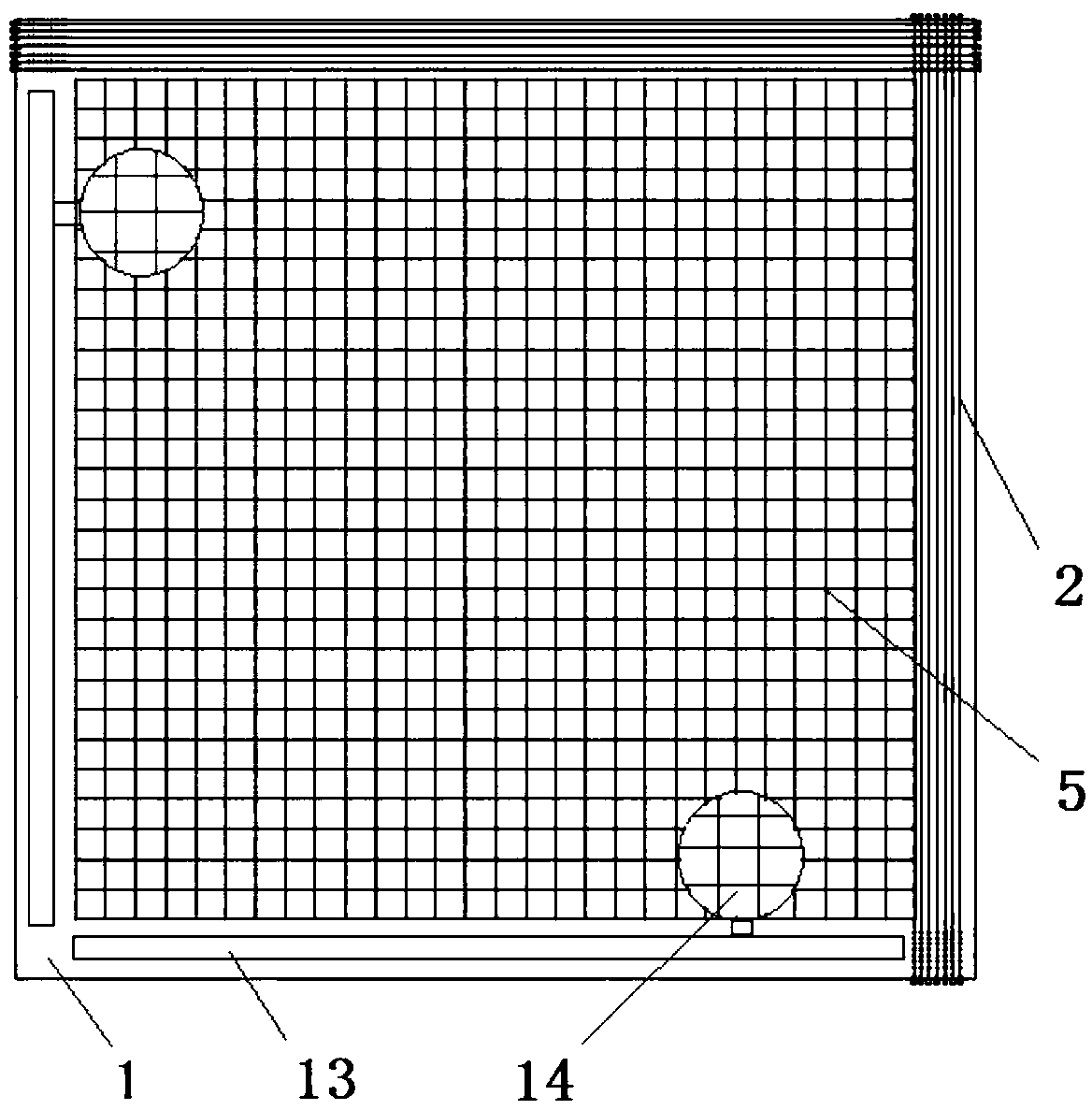

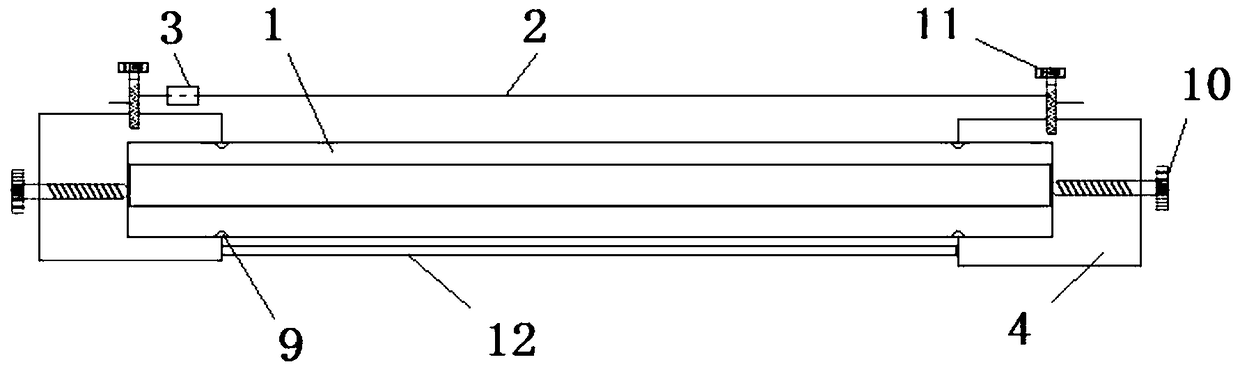

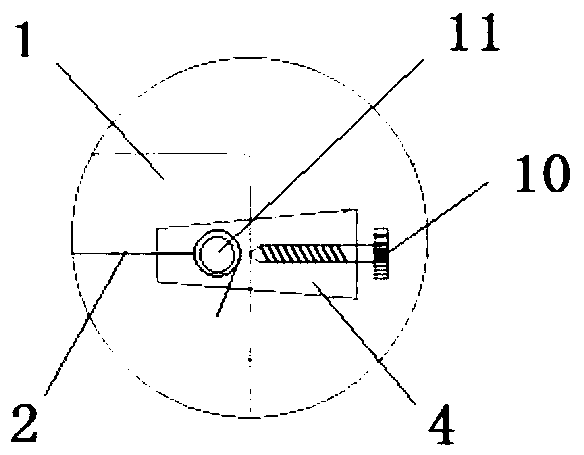

[0026] Such as Figure 1 to Figure 6 As shown, a curve plotter for processing special-shaped workpieces according to the present invention includes a bottom plate 1, a positioning wire 2 and a positioner 3 pierced through the positioning wire 2, and the positioning wire 2 and the moving blocks 4 at both ends thereof are provided with several The groups are arranged vertically and intersecting each other. The positioning drawing wire 2 is tensioned and flexibly connected to the two ends of the bottom plate 1 through the moving blocks 4 at both ends. The intersection of the scale grid 5 lines is provided with a positioning through hole 6 for drawing points, and the positioning drawing wire 2 is eccentrically passed through the positioner 3 to prevent the positioner 3 from sliding freely relative to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com