Pressure reducing valve

A pressure reducing valve and valve body technology, applied in the field of pressure reducing valves, can solve the problems of low sealing performance of the lower valve cover, reduced safety and reliability, poor sealing effect, etc., and achieve low production cost, simple structure, and stable pressure regulation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

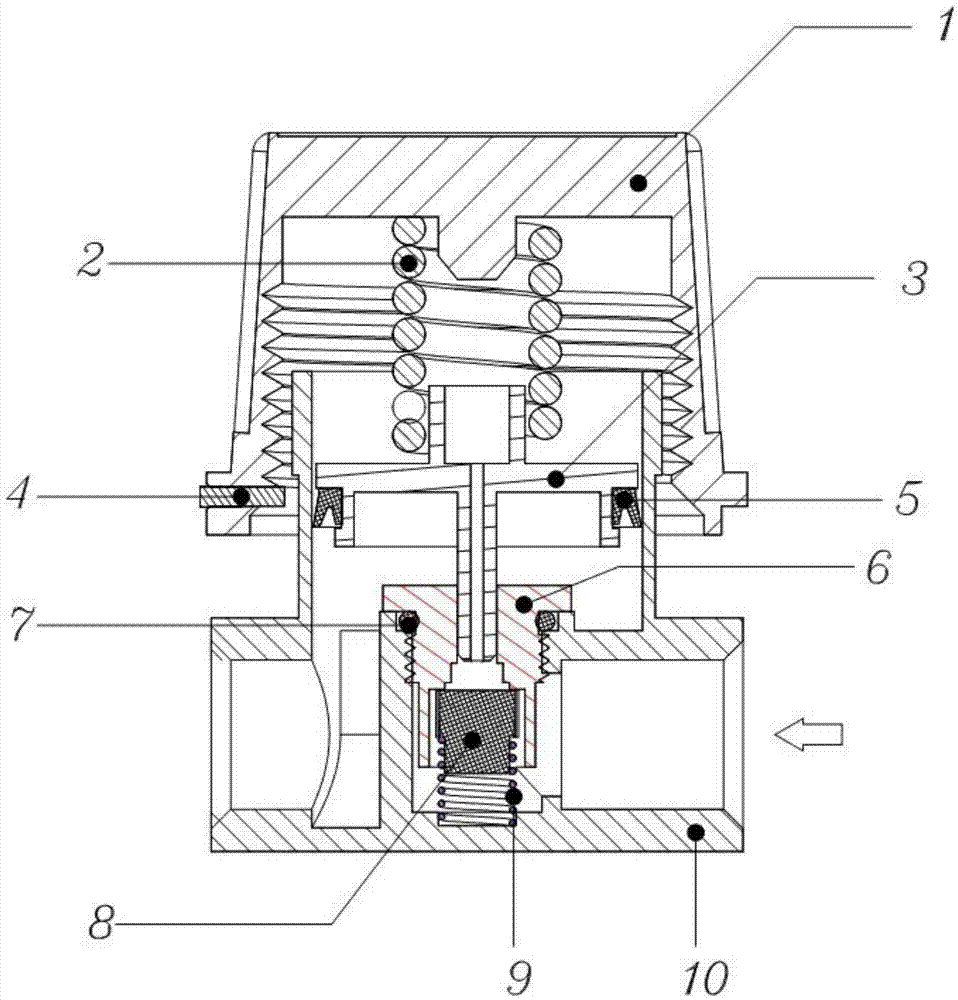

[0014] like figure 1 Shown: pressure reducing valve, its structure includes: bonnet 1, fixed value spring 2, piston 3, stop pin 4, Y-ring 5, fixed seat 6, O-ring 7, spring plunger 8, balance spring 9, Valve body 10; a valve body 10 with an inner cavity, a bonnet 1 sleeved on the outside of the valve body 10, fixedly connected with the valve body 10 and located at the top of the inner cavity, and the lower part of the bonnet 1 is fixedly installed There are fixed value springs 2 which are stretched or relaxed corresponding to the desired output pressure and which are more or less compressed or pretensioned by the fixed value spring 2 support as a result of a fixed value spring 2 If the adjustable pressure is insufficient, then a second fixed value spring 2 can be provided in the pressure adjustment unit, the fixed value spring 2 is arranged one inside the other, which means that two springs with different spring diameters are used so that they can Arranged one inside the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com