High-temperature gas cooled reactor end face sealing suction gun device

A high-temperature gas-cooled reactor and end-face sealing technology, which is applied to measuring devices, greenhouse gas reduction, fluid tightness testing, etc., can solve problems such as operating environment, structural tube sheet structure differences, etc., to reduce consumption time and reduce Effect of Radiation Dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

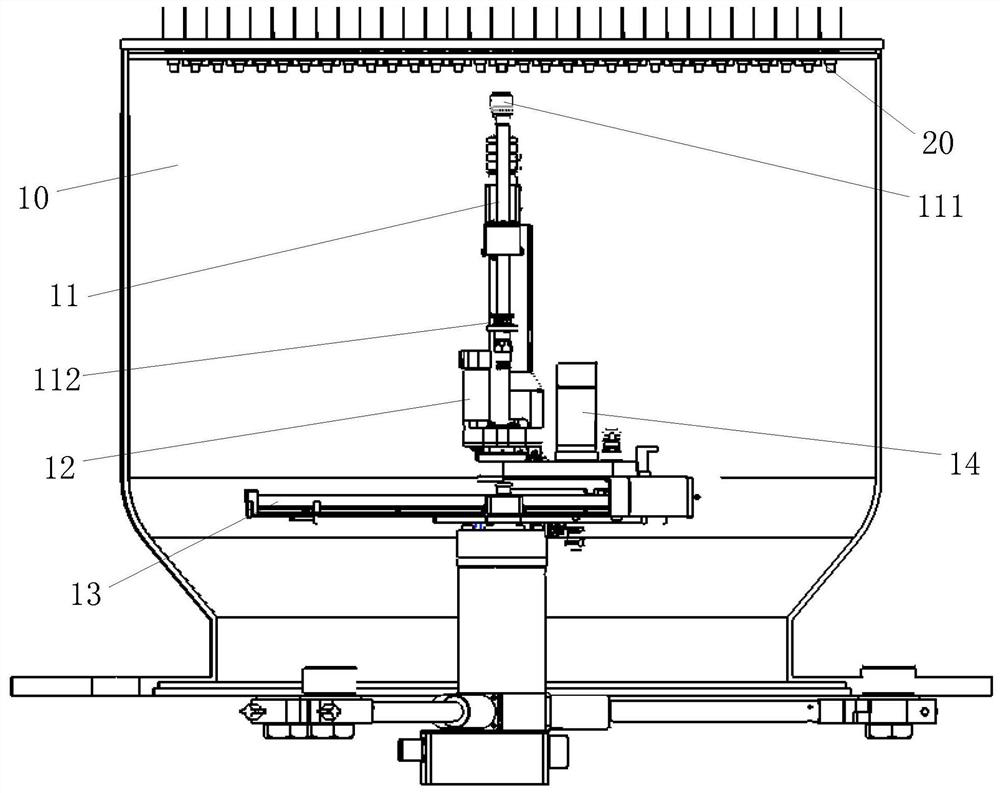

[0046] figure 1 It is a schematic diagram of a high-temperature gas-cooled reactor end face sealing sniffing lance device according to an exemplary embodiment. Such as figure 1 As shown, the high-temperature gas-cooled stack end face sealing sniffing device may include: a positioning assembly 13, a rotating assembly 14, a lifting assembly 12, at least one sniffing assembly 11 and a bracket 17;

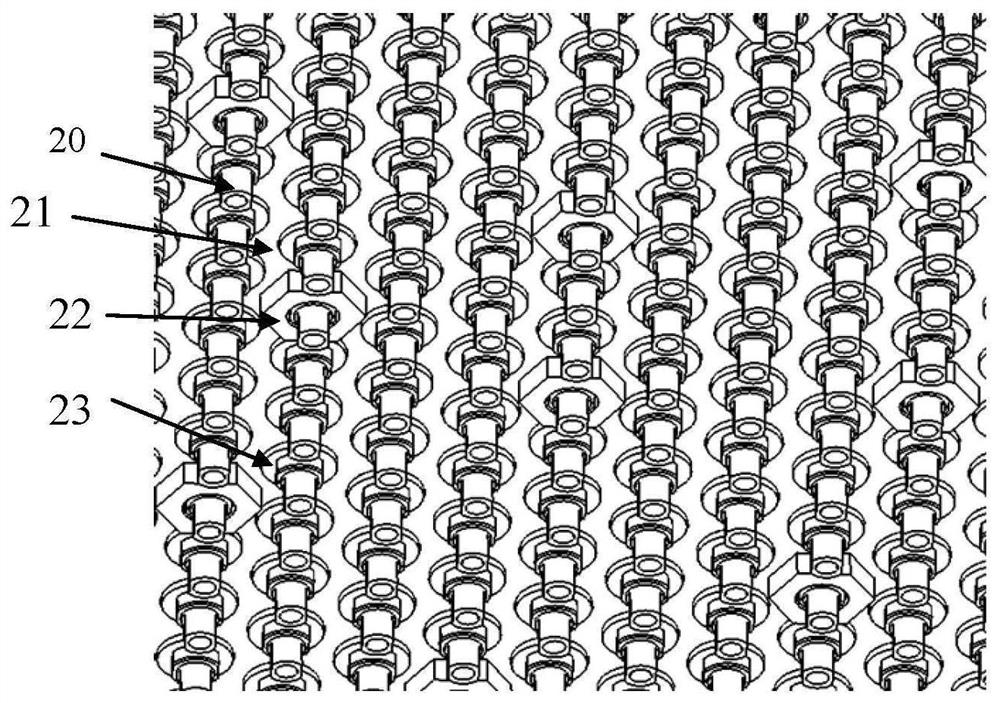

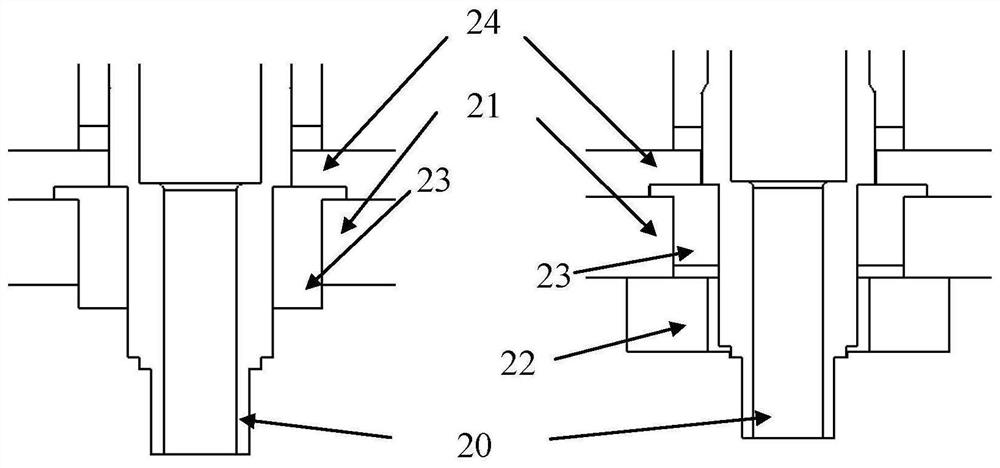

[0047] Generally speaking, such as figure 2 and image 3 As shown, the installation form of the throttling assembly at the feedwater inlet of the steam generator is composed of a throttling assembly 20 and an anti-loosening assembly. There are two types of installation with fixing nuts and without fixing nuts). The loosening plate can be arranged on the lower surface of the tube sheet 24. Due to the existence of the anti-loosening plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com