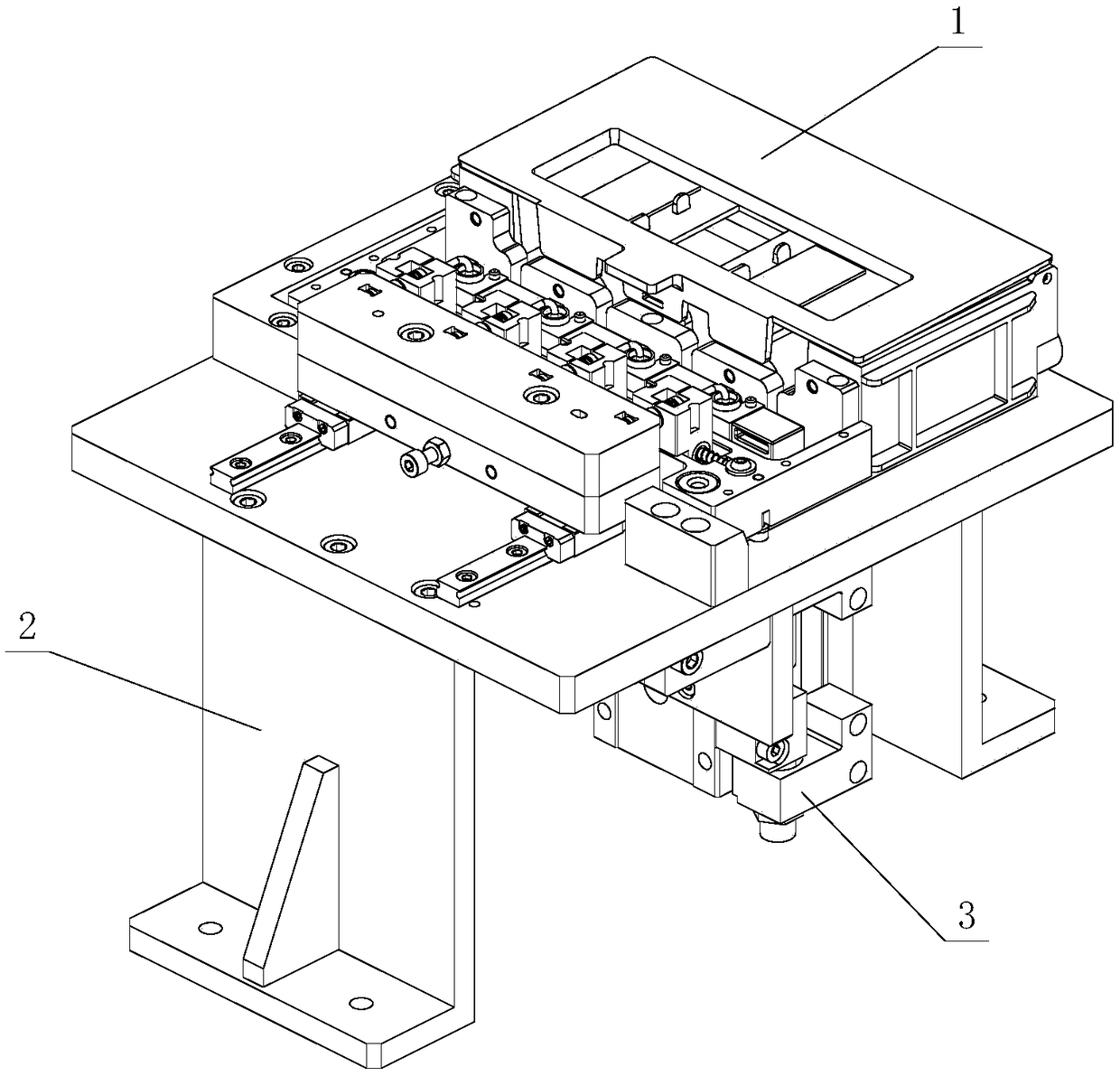

Jaws open product positioning mechanism

A positioning mechanism and jaw technology, applied in positioning devices, clamping, workpiece clamping devices, etc., can solve the problems of poor versatility of product positioning mechanisms, and achieve the effects of saving manpower, improving production efficiency, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, for illustrative purposes, many specific details are set forth in order to provide a comprehensive understanding of one or more embodiments. However, it is obvious that these embodiments can also be implemented without these specific details.

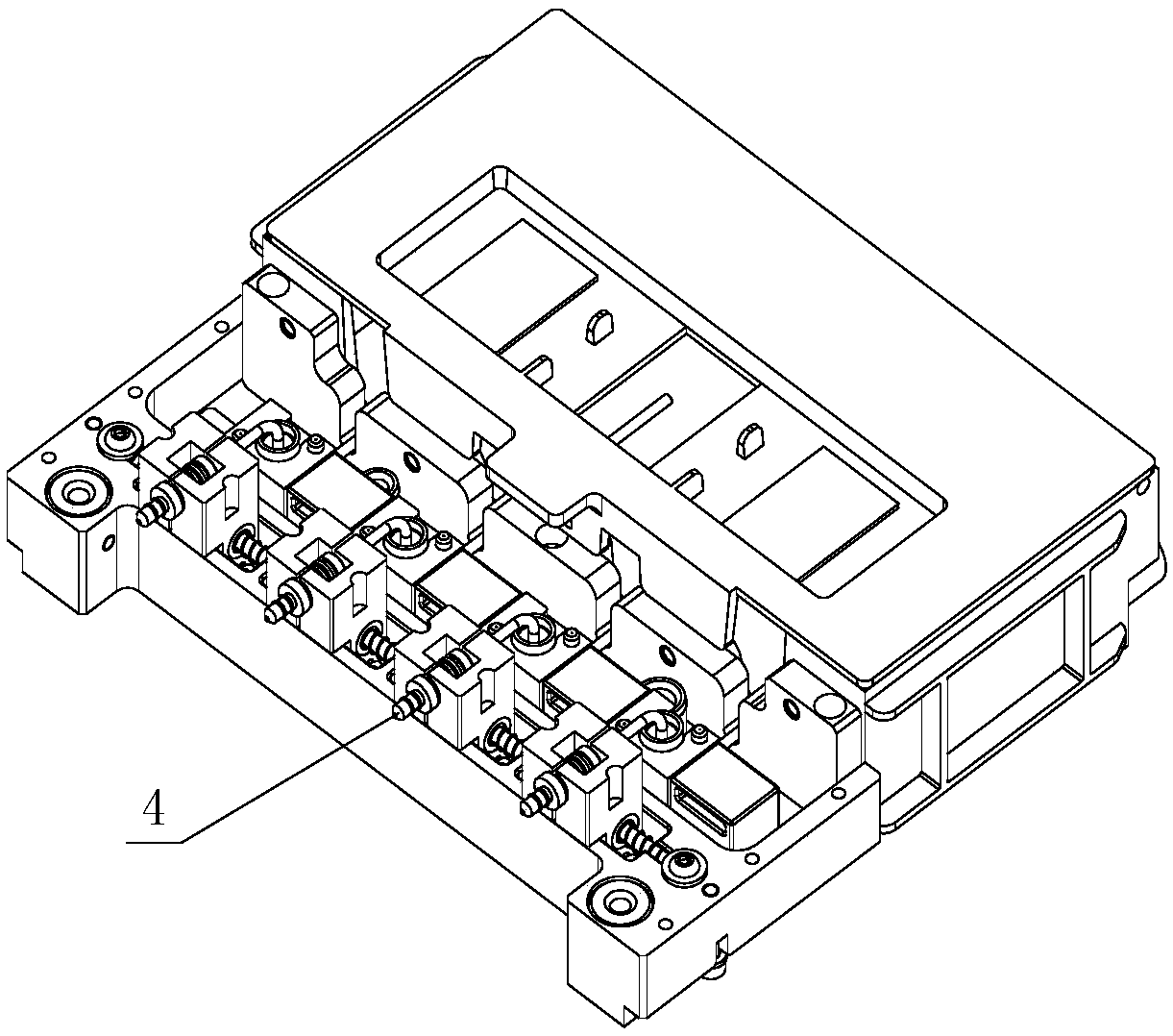

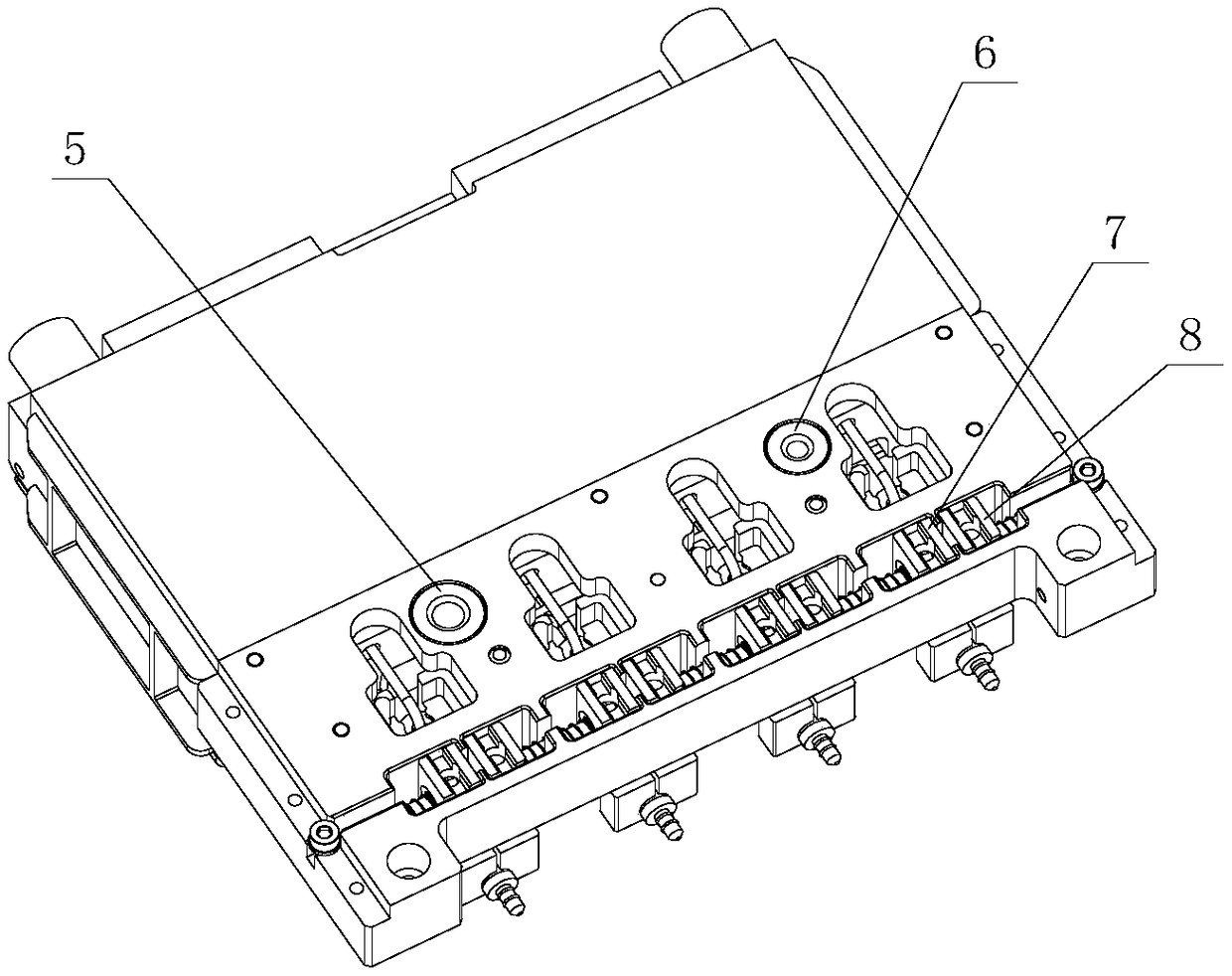

[0032] In view of the aforementioned problem of poor versatility of the existing product positioning structure, the present invention proposes a clamping jaw opening product positioning mechanism. The present invention matches the automatic general tooling to realize the repositioning of the product. Among them, a variety of positioning methods such as different size pin positioning, edge positioning, magnet positioning and profiling guidance are used to improve the processing accuracy of the product; the product is released at different positions to assist in the completion of the product rotation, flipping and other actions; After the processing is completed, the product can be positioned and clamped ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap