A construction method of basement retaining wall based on brick membrane molding wall

A construction method and technology for basement, which are applied in basic structure engineering, excavation, artificial island, etc., can solve problems such as difficult construction, close distance between basement retaining wall and foundation pit support system, and difficulty in supporting formwork outside the retaining wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

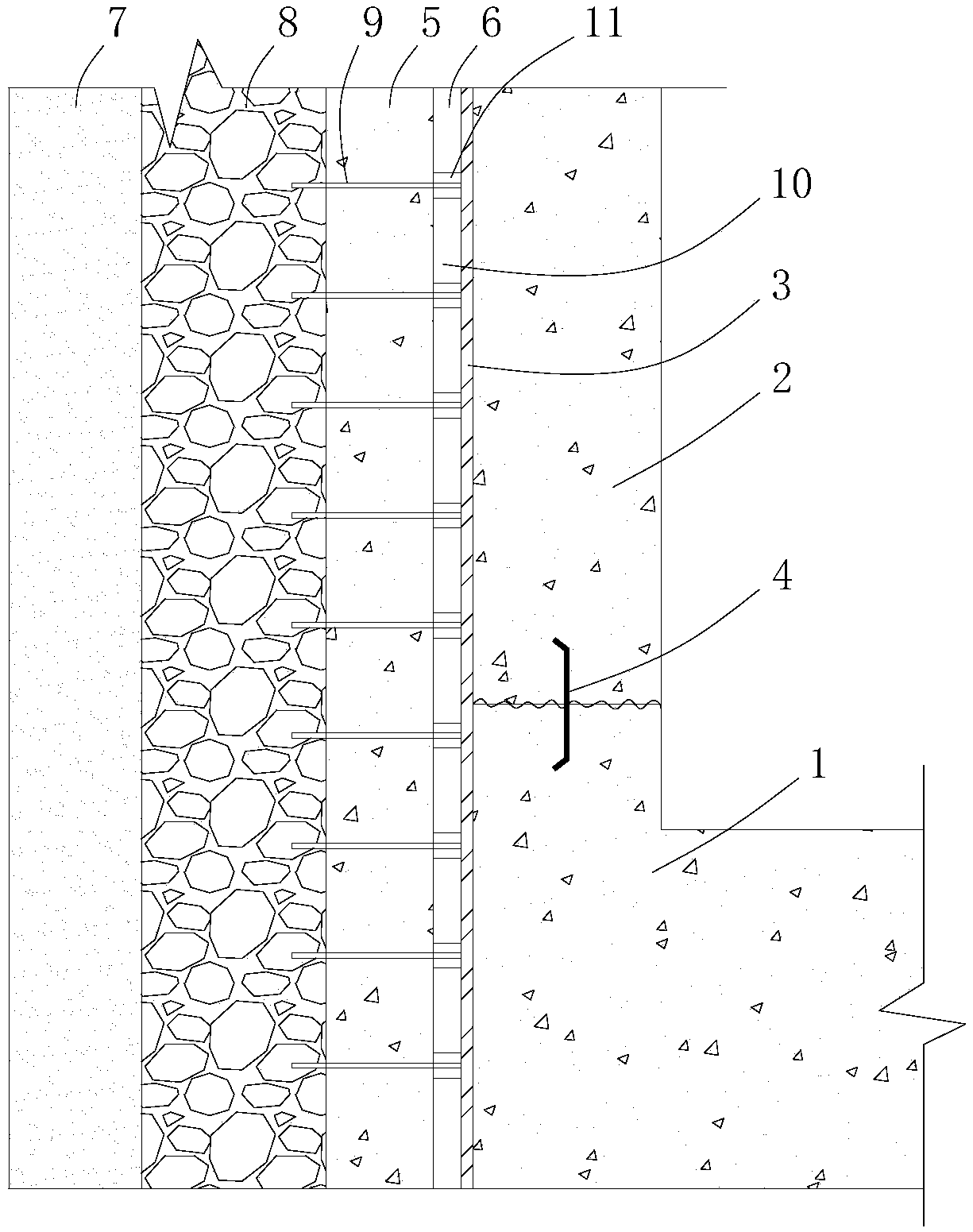

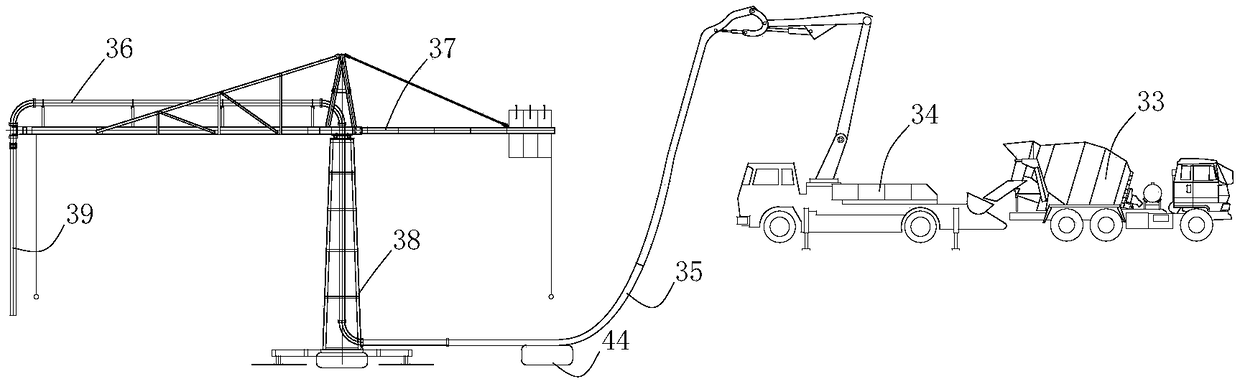

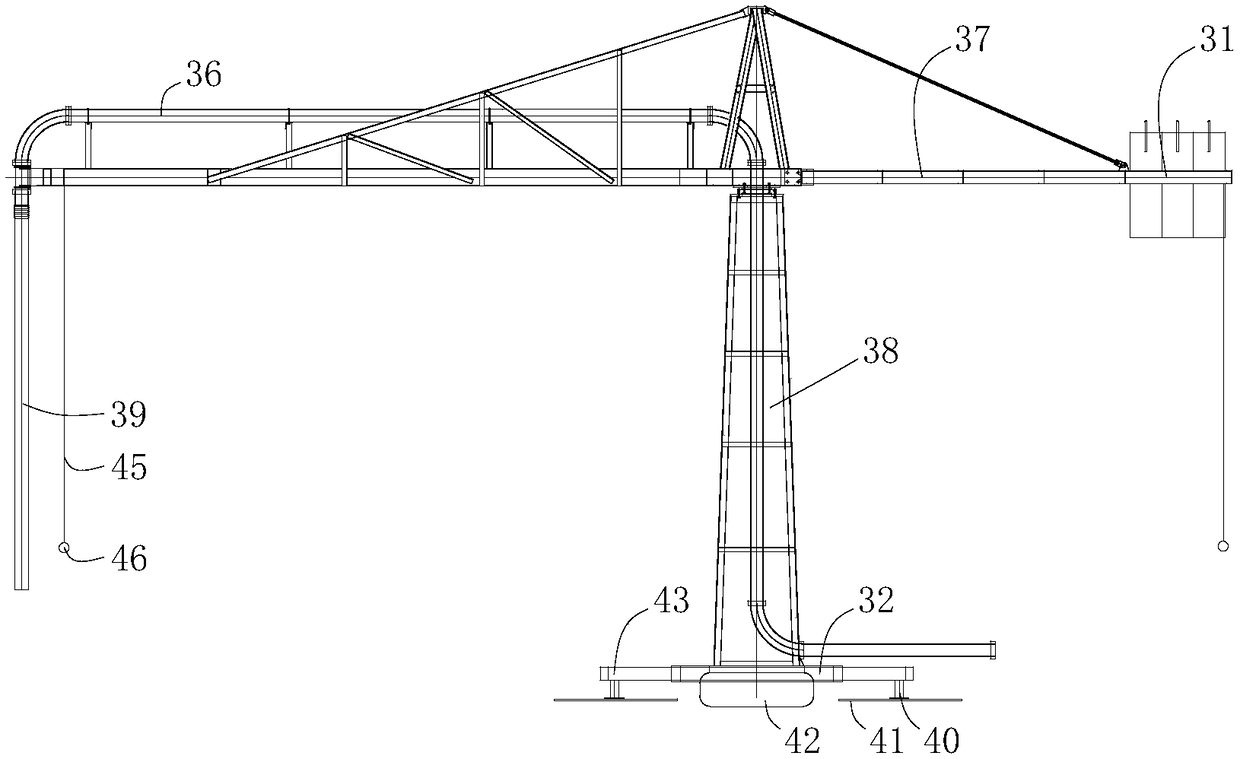

[0063] A construction method for a basement retaining wall based on a brick-formed membrane molding wall. First, a molding wall is set on the wall of a foundation pit in a basement. The outer surface of the molding wall and the outer surface of the basement retaining wall have the same design shape, and then the outer surface of the molding wall is waterproofed. The waterproof layer of the retaining wall is obtained by coil construction, and the outer support of the basement retaining wall is formed by the modeling wall and the retaining wall waterproof layer. The basement retaining wall reinforcement is bound and the inner side of the retaining wall is unilaterally supported to complete the pouring of the basement retaining wall. For masonry, the modeling wall is set on the foundation pit wall of the basement, and the molding concrete is poured after setting the brick membrane, which specifically includes the following steps:

[0064] 1) Pre-buried support piles vertically out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com