Basement retaining wall without fertilizer tank construction

A technology for basements and retaining walls, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of difficult construction, difficult to set up formwork on the outer side of the retaining wall, and short distances, so as to ensure the strength and reliability of the support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

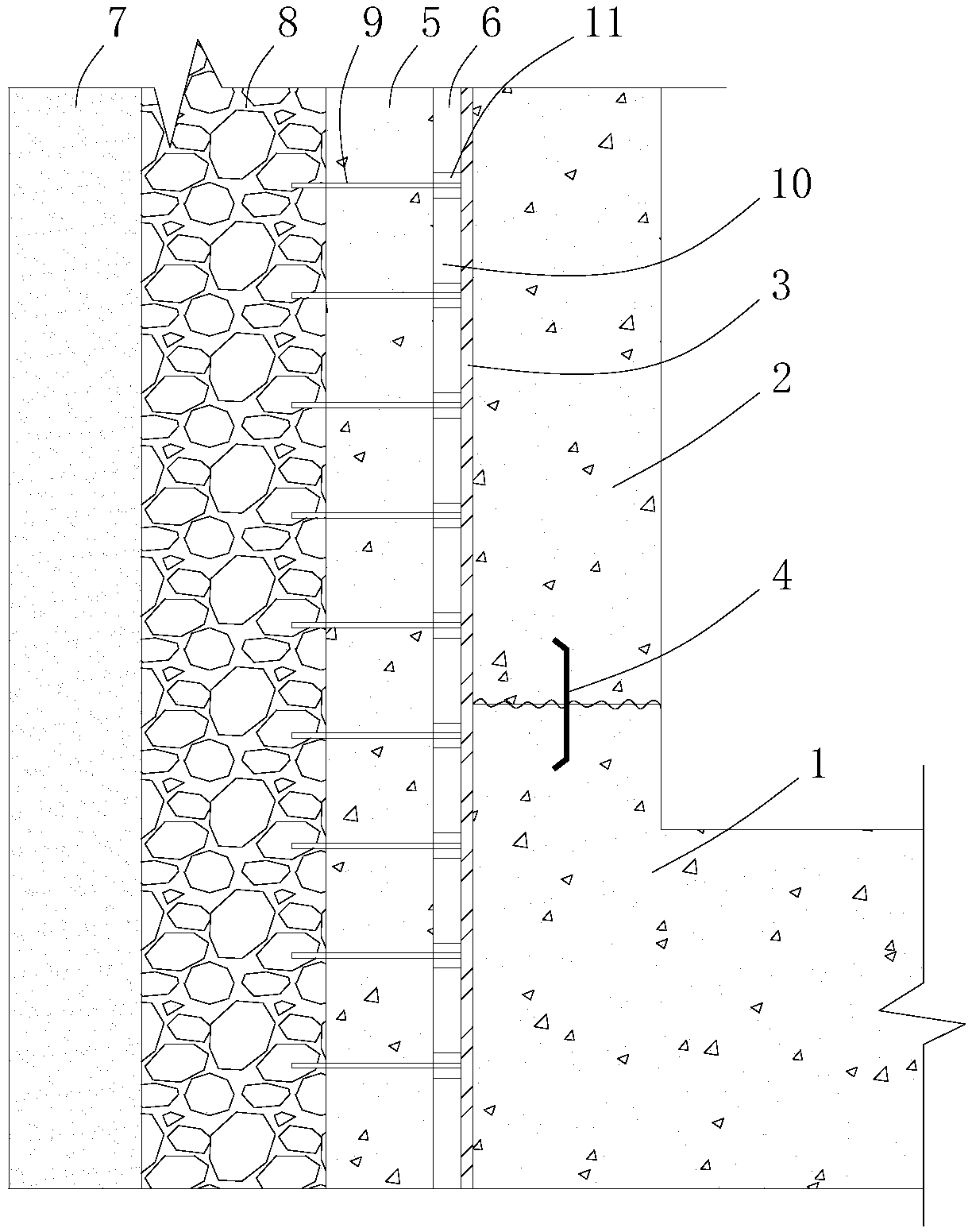

[0068] join figure 1 , a basement retaining wall constructed without a fertilizer tank, comprising a basement retaining wall body 2 poured and arranged on a preset retaining wall foundation on the surface of a basement pit, and a waterproof layer made of waterproof coiled material is arranged on the outer side of the basement retaining wall body 2 3. It is characterized in that the exterior of the waterproof layer 3 is provided with a molding wall, the main body of the molding wall is obtained by pouring concrete, and the outer side of the molding wall is connected with the pouring of the foundation pit wall; the soil layer 7 outside the foundation pit wall also has a vertically buried Supporting pile 8, a welding screw 9 is arranged horizontally between the supporting pile 8 and the brick wall, one end of the welding screw 9 is welded and fixed in the opening of the supporting pile 8, and the other end of the welding screw 9 is pulled and fixed on the shape inside the wall. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com