3D four-wheel position indicator for intelligently capturing target image and control method thereof

A technology of four-wheel aligner and target target, which is applied in the direction of using feedback control, program control, computer control, etc., and can solve problems such as low operating efficiency and inaccurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

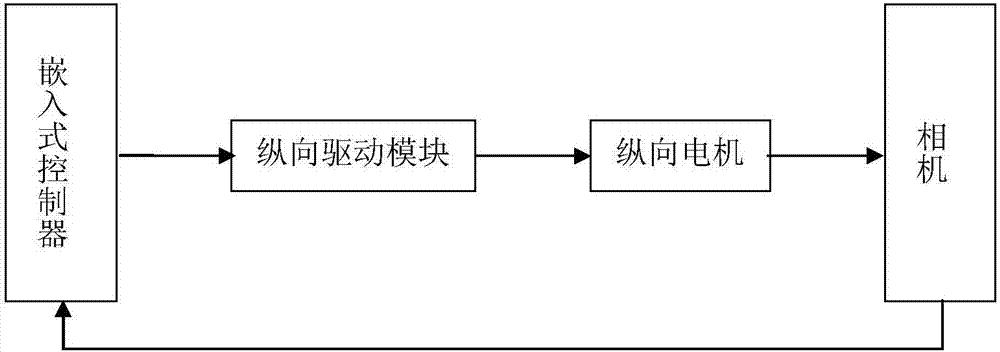

Embodiment 1

[0044] A 3D four-wheel aligner that intelligently captures target images, such as figure 1 As shown, it is mainly composed of target target, camera, camera beam, camera column, lift and camera control components. The camera control assembly includes a vertical motor, a vertical drive module and an embedded controller. The target is mounted on the wheel hub of the car to be tested. The car to be tested is on the ground or on a lift. In order to realize the automatic adjustment of the shooting height of the camera, in this embodiment, the camera is fixedly installed on the camera beam, and the camera beam is movably installed on the camera column. The camera, the camera beam and its camera column can be arranged at the front end of the lift together, and can also be arranged at the rear end of the lift together. However, in order to facilitate the entry of the wheels to be detected, in this embodiment, the camera, the camera beam and its camera post can be co-located on the f...

Embodiment 2

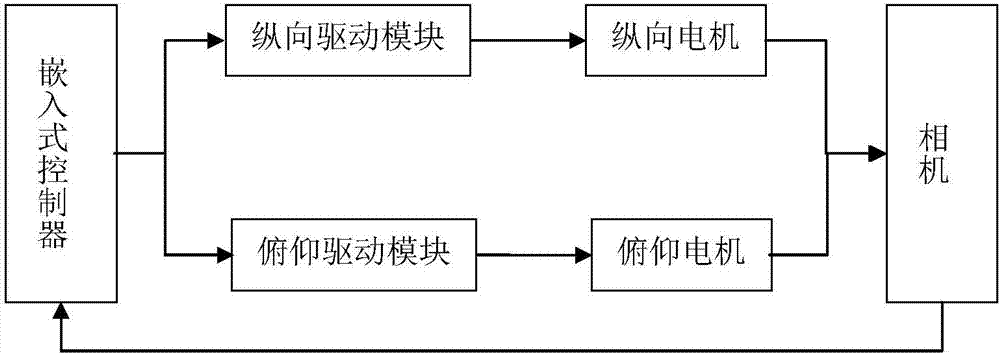

[0057] Embodiment 2 is further improved on the basis of Embodiment 1. Embodiment 1 can only realize the vertical height adjustment of the camera, that is, the camera is fixedly installed on the camera beam, and the camera beam is movably installed on the camera column. However, Embodiment 2 can not only realize the vertical height adjustment of the camera, but also can realize the vertical pitch angle adjustment of the camera, that is, the camera control assembly further includes a pitch motor and a pitch drive module. The camera is installed on the camera beam through the pitching bracket, and can perform pitching motion on the camera beam under the drive of the pitching motor. The pitch control output end of the embedded controller is connected to the pitch motor via the pitch drive module.

[0058] Specifically, a 3D four-wheel aligner that intelligently captures target images, such as figure 2 As shown, it is mainly composed of target target, camera, camera beam, camera ...

Embodiment 3

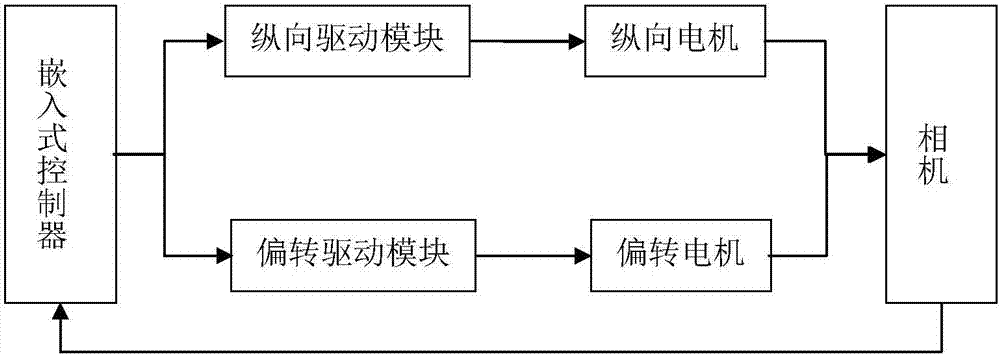

[0064] Embodiment 3 is further improved on the basis of Embodiment 1. Embodiment 1 can only realize the vertical height adjustment of the camera, that is, the camera is fixedly installed on the camera beam, and the camera beam is movably installed on the camera column. However, Embodiment 3 can not only realize the vertical height adjustment of the camera, but also can realize the horizontal deflection angle adjustment of the camera, that is, the camera control assembly further includes a deflection motor and a deflection drive module. The camera is installed on the camera beam through the deflection bracket, and can perform deflection movement on the camera beam under the drive of the deflection motor. The deflection control output end of the embedded controller is connected to the deflection motor via the deflection drive module.

[0065] Specifically, a 3D four-wheel aligner that intelligently captures target images, such as image 3 As shown, it is mainly composed of targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com