A preparation method suitable for non-uniform sweating skin of fabric sweating thermal manikin

A thermal manikin and skin technology, applied in textile testing, material thermal analysis, instruments, etc., can solve the problems of reducing service life, increasing the risk of skin rupture, reducing the strength of fabrics, etc., and achieve the effect of uneven sweating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

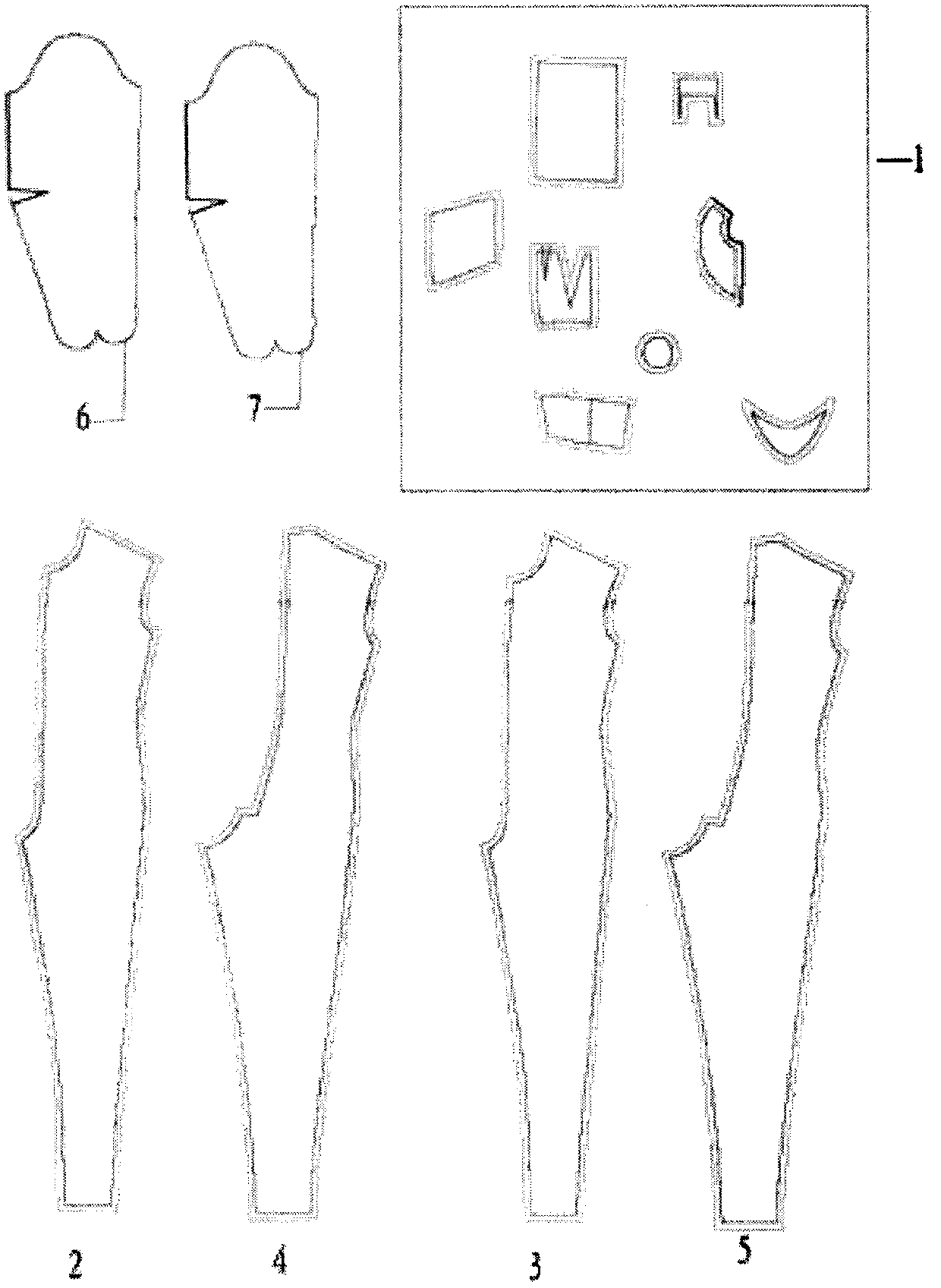

[0020] Connect the left front body piece 2 and the right front body piece 3 to form the front body piece, connect the left back body piece 4 and the right back body piece 5 to form the back body piece, connect the front body piece and the back body piece To form a body cut piece, the left sleeve cut piece 6 and the right sleeve cut piece 7 are respectively connected to the cuffs of the body cut piece, and the head cut piece 1 is connected to the neck of the body cut piece.

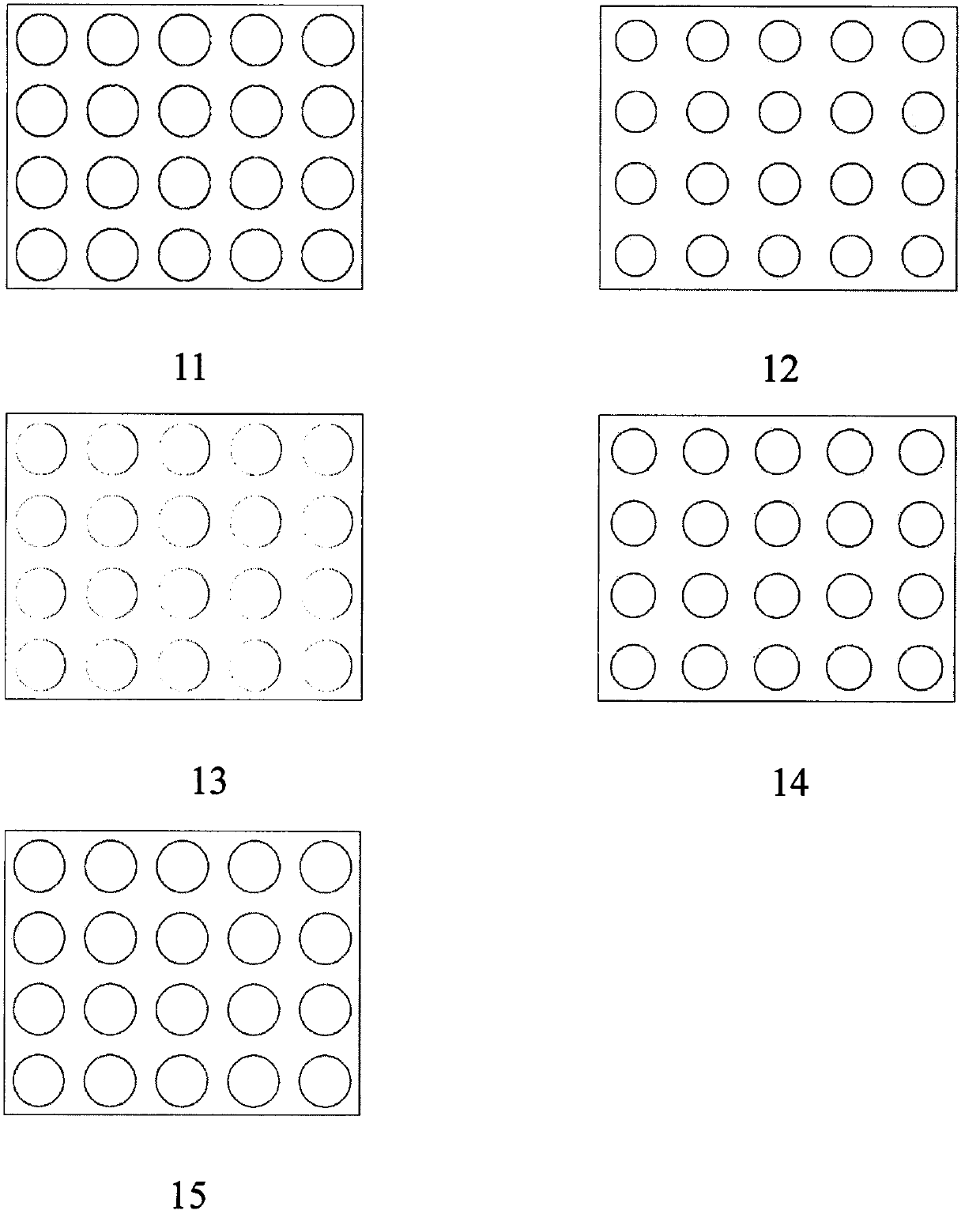

[0021] Among them, the left sleeve piece 6 and the right sleeve piece 7 use a template 11 with a hollow area of 90% to be composited with liquid addition-type silica gel; the left front body piece 2 and the right front body piece 3 above the abdomen use a template with an area of 85% hollow out 12 is compounded with liquid addition-type silica gel; left front body piece 2 and right front body piece 3 are composited with a template 13 hollowed out with 80% of the area below the abdomen; left back body pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com