Multifunctional integrated prefabricated pumping station top cover and method

A multi-functional, pumping station technology, which is applied to pumping stations, waterway systems, drainage structures, etc., can solve the problem that the top cover is not universal, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A multifunctional integrated prefabricated pump station top cover of the present invention will be further described below in conjunction with the accompanying drawings.

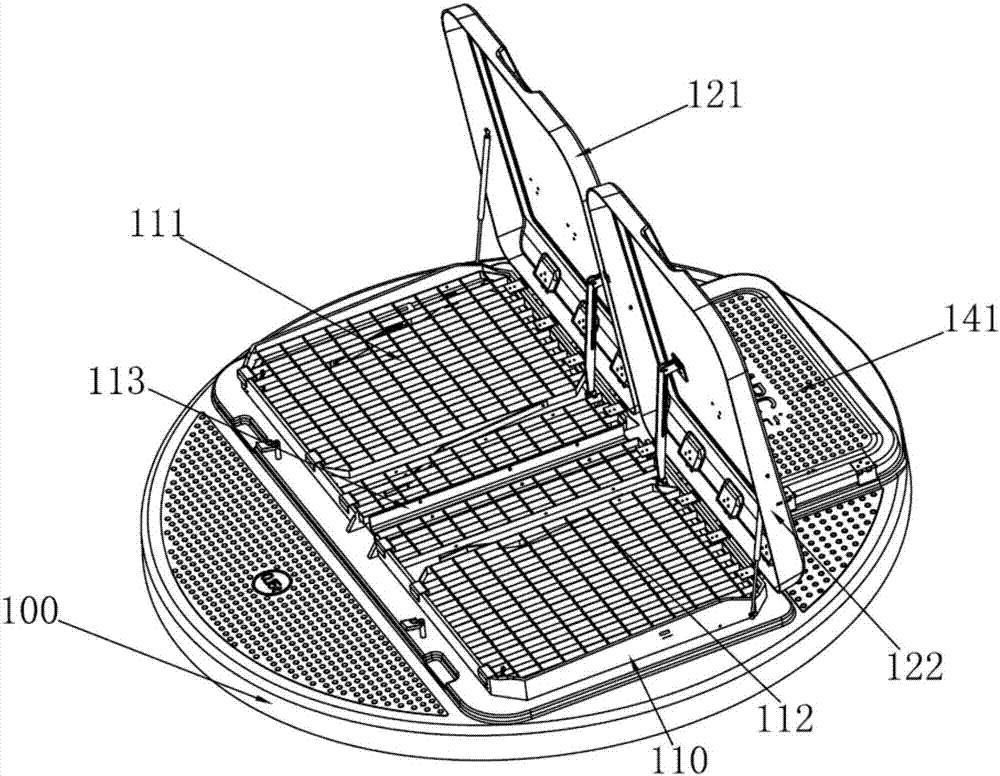

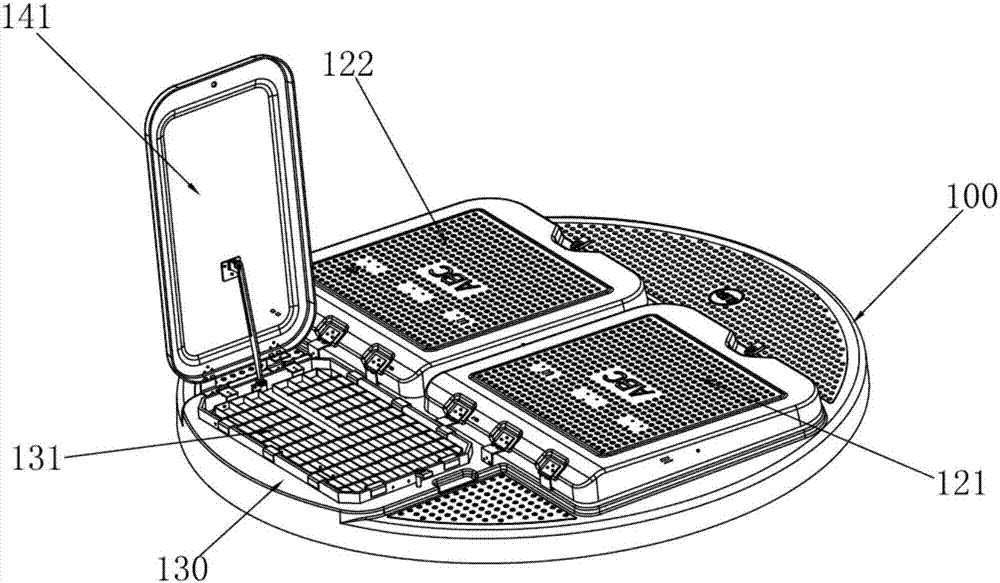

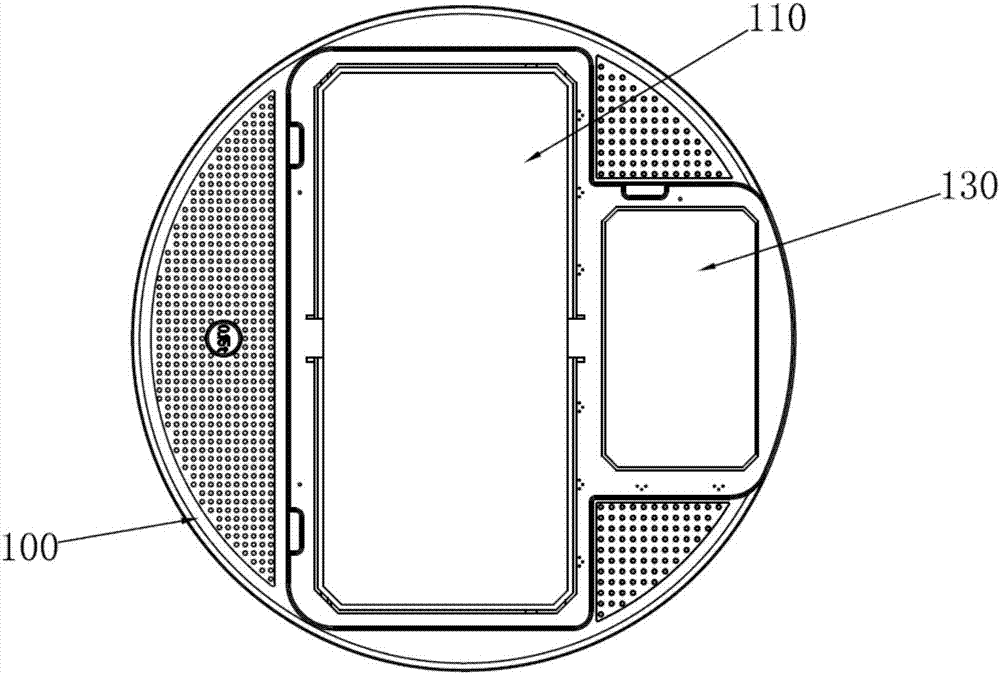

[0051] Such as Figure 1-10 shown, see figure 1 , 2 , 7, a multi-functional integrated prefabricated pump station top cover, including:

[0052] The cover seat 100 is located on the top of the integrated prefabricated pump station, and has a pump hole 110. The pump hole 110 is provided with a storage room for the pump, and the pump hole 110 is provided with a pump hole grille. The pump hole grid includes a first grid 111 , a second grid 112 , and a connecting piece 113 , and the first grid 111 and the second grid 112 are connected by the connecting piece 113 .

[0053] The present invention connects the first grid 111 and the second grid 112 through the connecting piece 113, so that the pump hole grid of the present invention can be bent adaptively, thereby achieving the effect that the pump hole g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap