Axles for wheels of double-track motor vehicles and double-track motor vehicles having such axles

A technology for motor vehicles and wheels, applied in vehicle springs, vehicle components, transportation and packaging, etc., can solve problems such as no lateral force, and achieve the effect of less structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

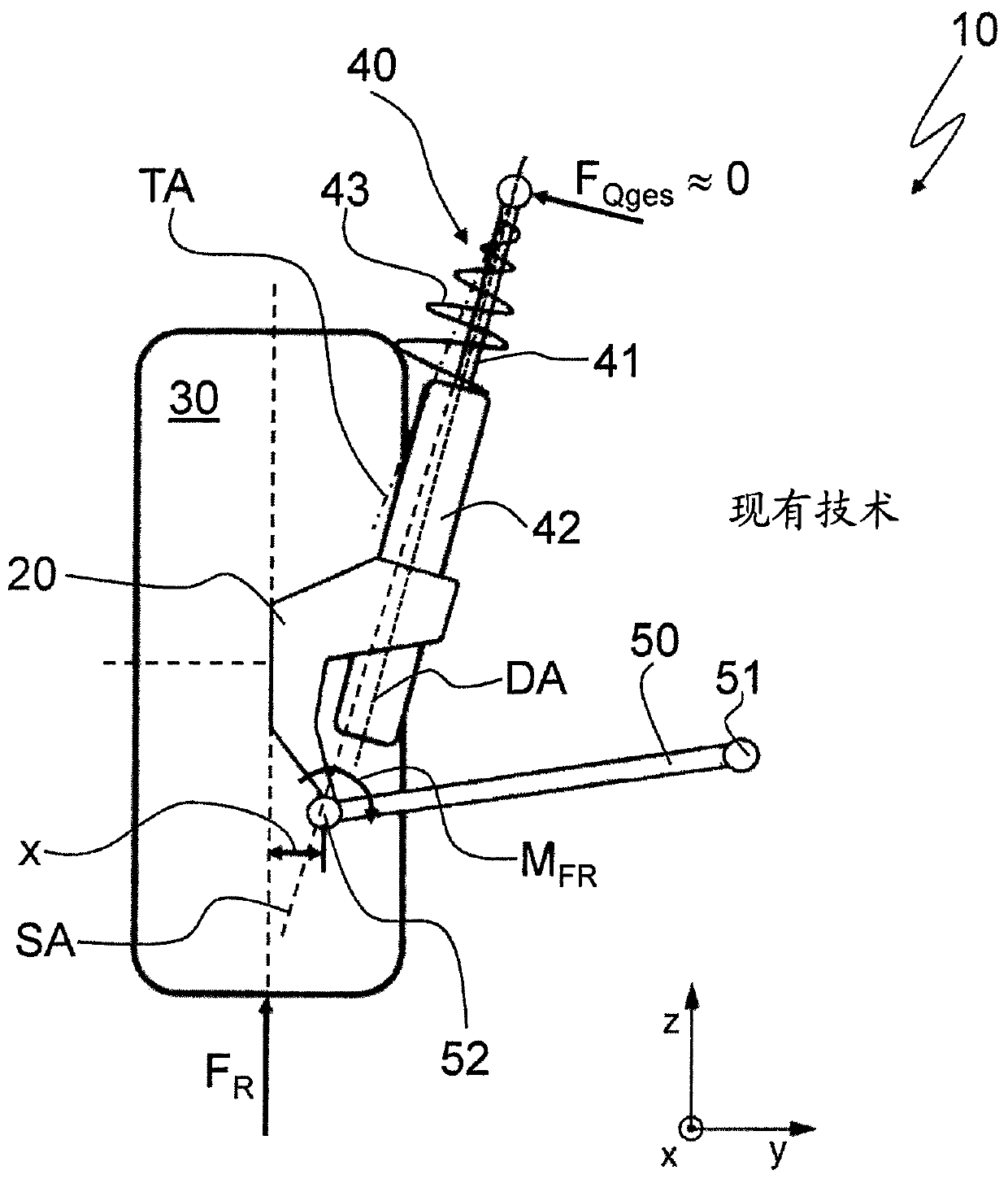

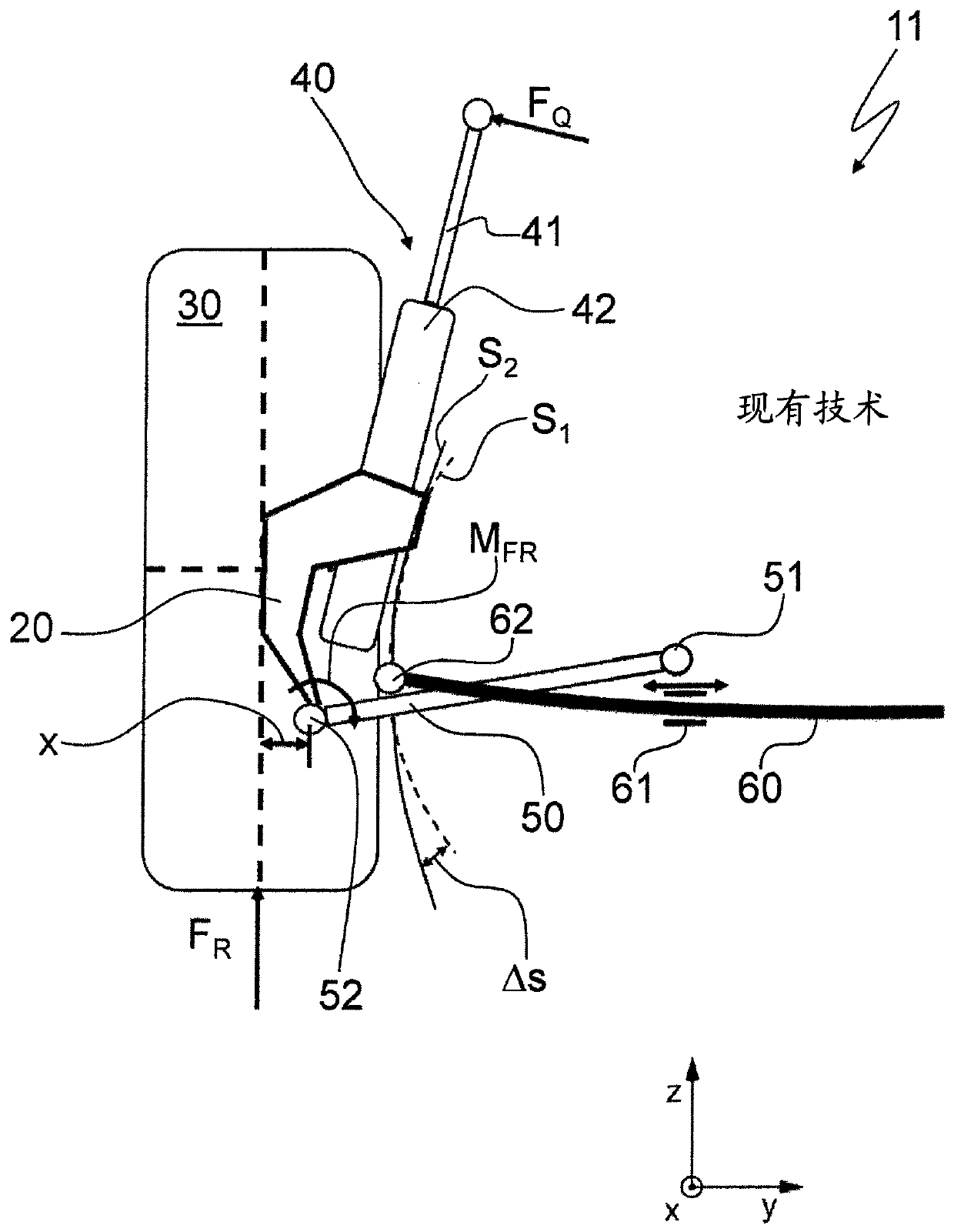

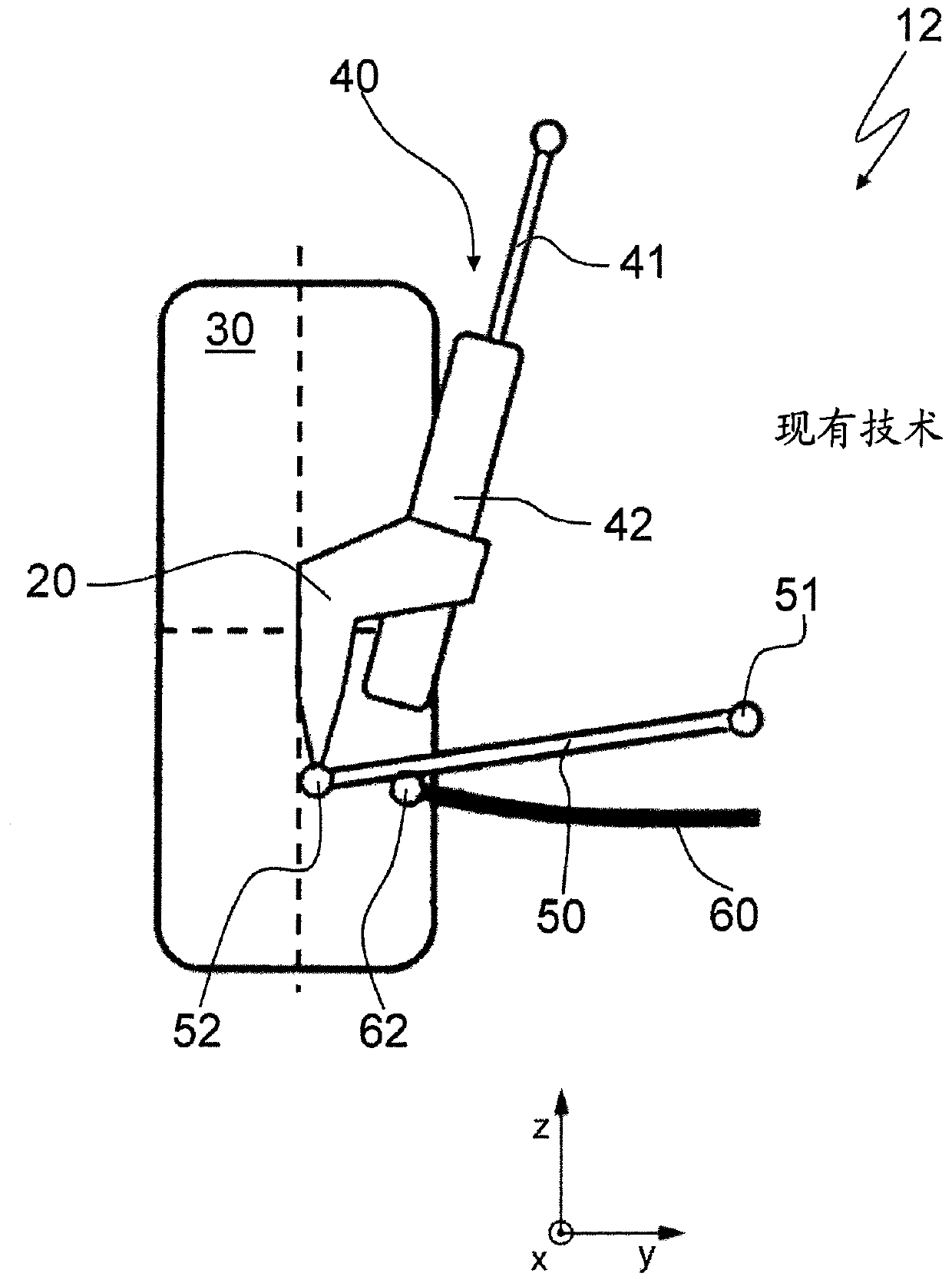

[0050] figure 1 Shown is a spring strut axle 10 known from the prior art with a wheel 30 wheel carrier 20 for receiving the axle 10 , comprising a damper tube 42 and a damper piston 41 and a helical spring 43 or damper of the support spring 43 The vibration absorber 40 is supported on this wheel carrier, the vibration absorber 40 forms a spring strut with the coil spring or support spring. In this case, the shock absorber 40 can be connected to the vehicle structure via its upper connection point on the shock absorber piston 41 . In the lower region of the shock absorber, the shock absorber 40 is supported with its damper tube 42 on the wheel carrier 20 .

[0051] A lower transverse link 50 is likewise supported on the wheel carrier 20 , said lower transverse link being connected with its end on the wheel carrier side to the wheel carrier by means of a joint 52 . The upper connection point of the shock absorber 40 and the articulation connection 52 here define, in the steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com