Floating block of hub shaping die

A floating block and mold technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large heat treatment deformation, high cost, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

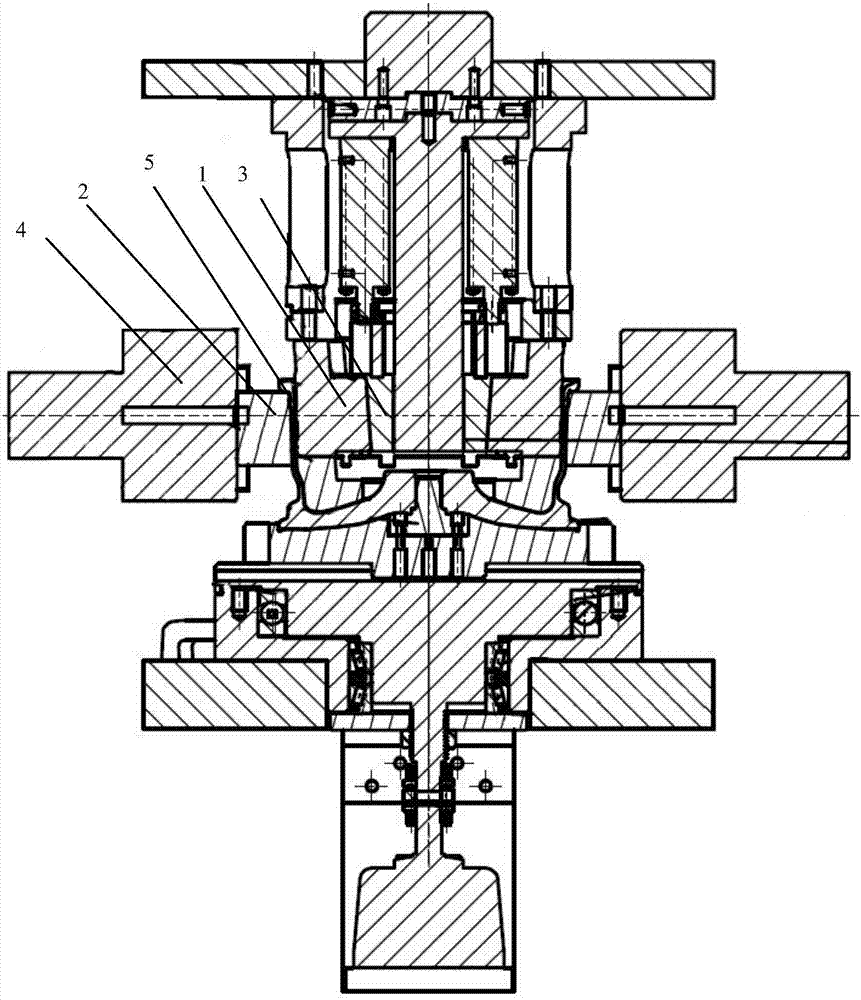

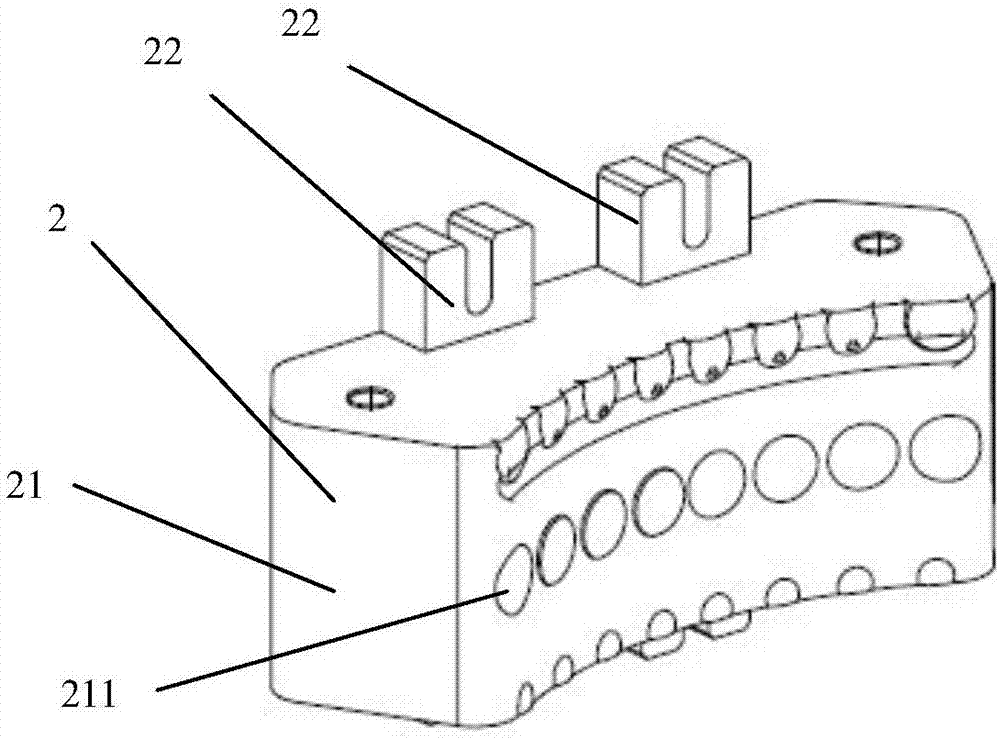

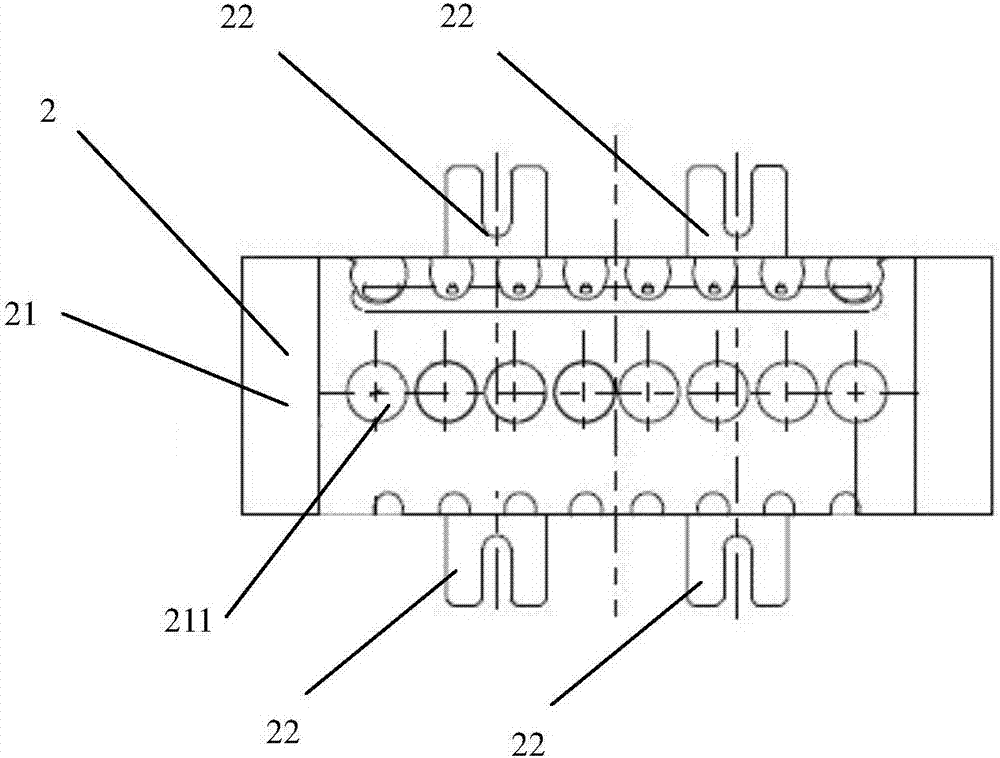

[0038] In a further embodiment of the present invention, the concave arc surface matches the outer surface of the hub 5 , and the convex arc surface matches the inner surface of the hub 5 .

[0039] In a further embodiment of the present invention, several dot-shaped inner stays 1 and dot-shaped outer pressure pieces 2 are included, and the number of dot-shaped inner stays 1 matches the number of dot-shaped outer pressure pieces 2 . Each dot-shaped inner stay 1 and a dot-shaped outer pressure piece 2 are arranged oppositely, and the inner drive mechanism 3 and the outer drive motor 4 work to make each pair of dot-shaped inner stays 1 and dot-shaped outer pressure pieces 2 move closer together. Pressing and closely adhering to the inner wall and outer wall of the hub 5, the arc surface of the point-shaped inner support piece 1 and the point-shaped outer pressing piece 2 generates pressure on the hub 5, thereby shaping the hub 5.

[0040] In a further embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com