Floating block of wheel hub shaping mold

A floating block and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, high cost, and increased material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

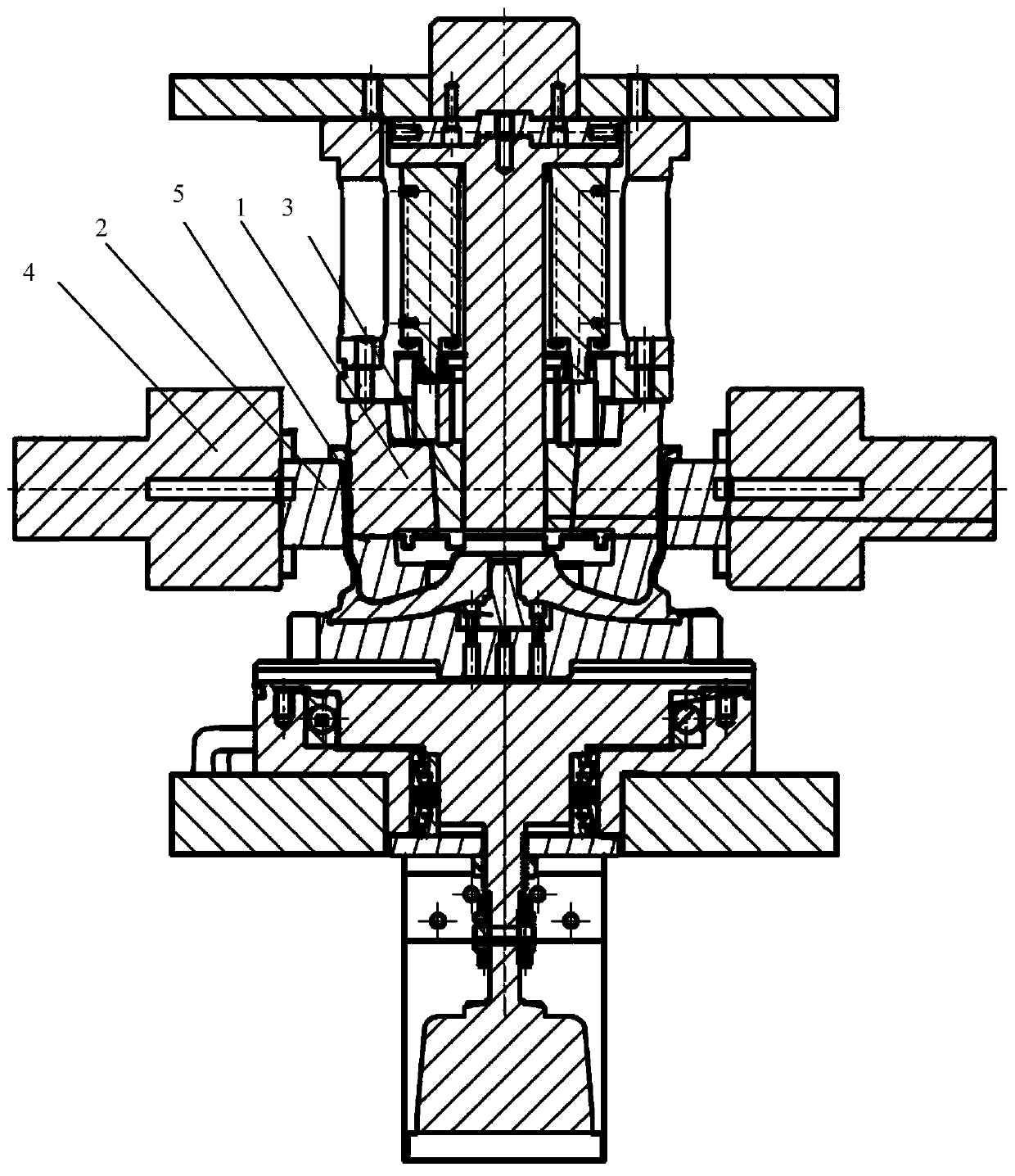

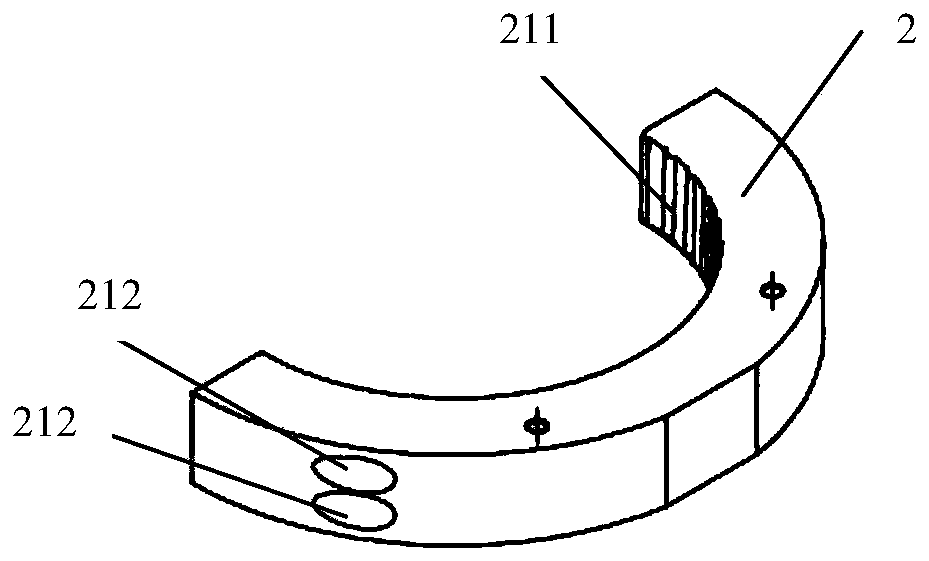

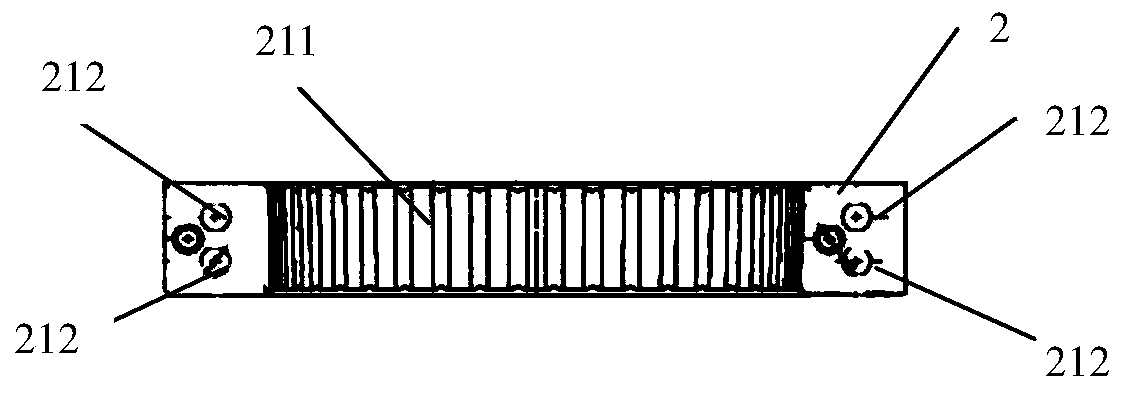

[0038] In a further embodiment of the present invention, the concave arc surface matches the outer surface of the hub 5 , and the convex arc surface matches the inner surface of the hub 5 .

[0039] In a further embodiment of the present invention, it includes some dot-shaped inner struts 1, the convex arc surfaces of some dot-shaped inner struts 1 form a circular structure, and the circular structure formed by several dot-shaped inner struts 1 is combined with the two-shaped external pressure Piece 2 matches He Weicheng's ring structure. A number of dot-shaped inner struts 1 and two tooth-shaped outer pressure pieces 2 are arranged facing each other, and the inner drive mechanism 3 and the outer drive motor 4 work to make each pair of dot-shaped inner struts 1 and tooth-shaped outer pressure pieces 2 move closer together. , press fit, close to the inner wall and the outer wall of the hub 5, and the arc surface of the point-shaped inner support piece 1 and the tooth-shaped out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com