Patents

Literature

35results about How to "Achieve plastic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

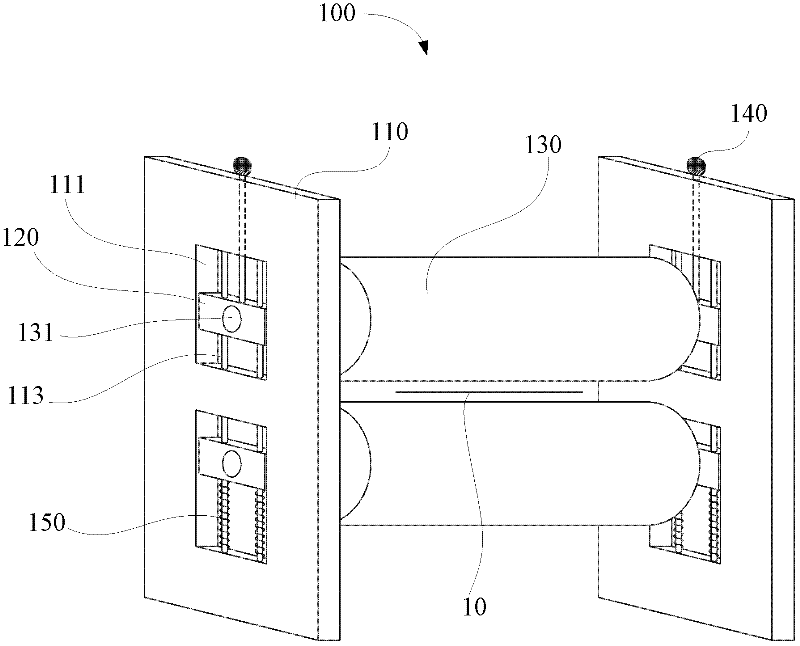

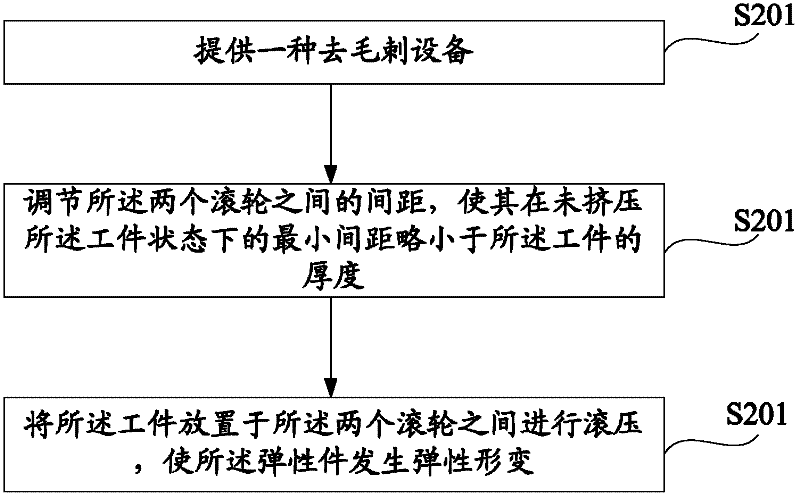

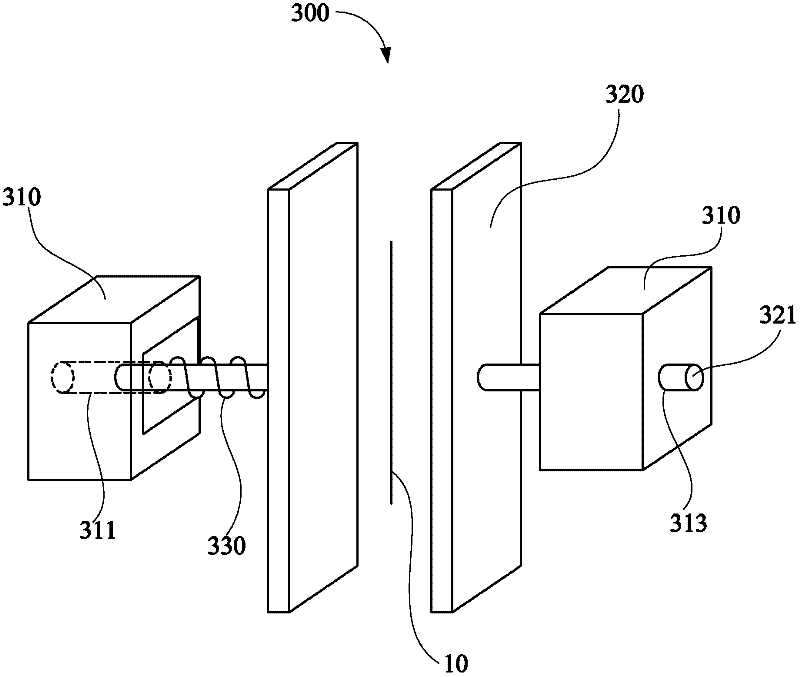

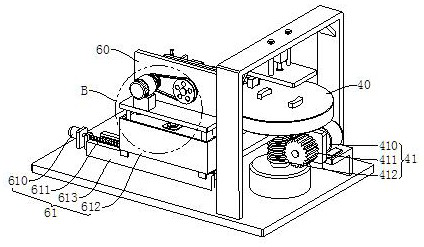

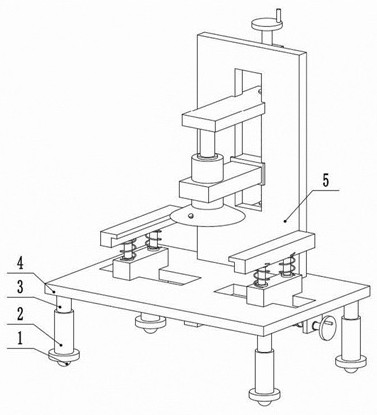

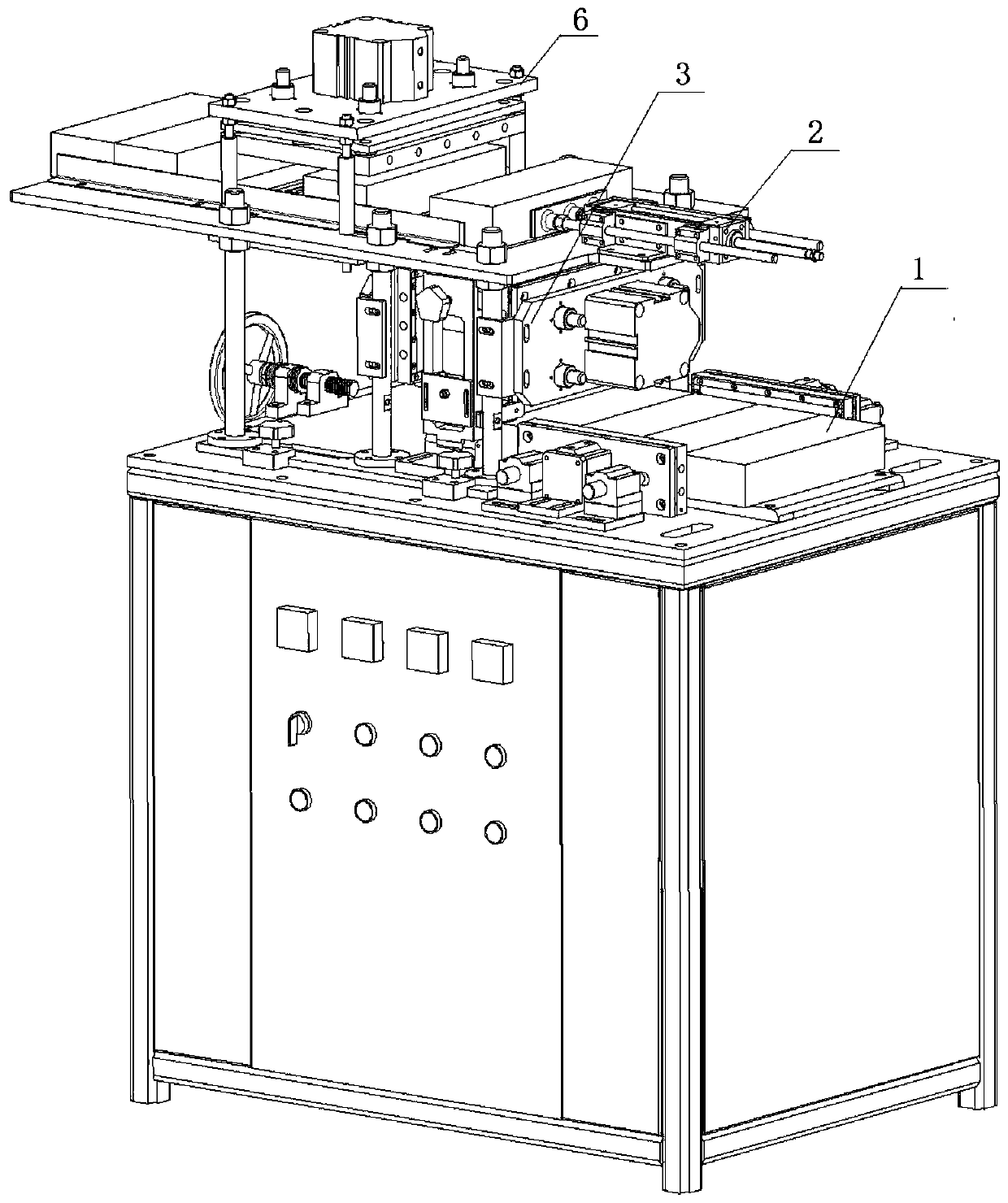

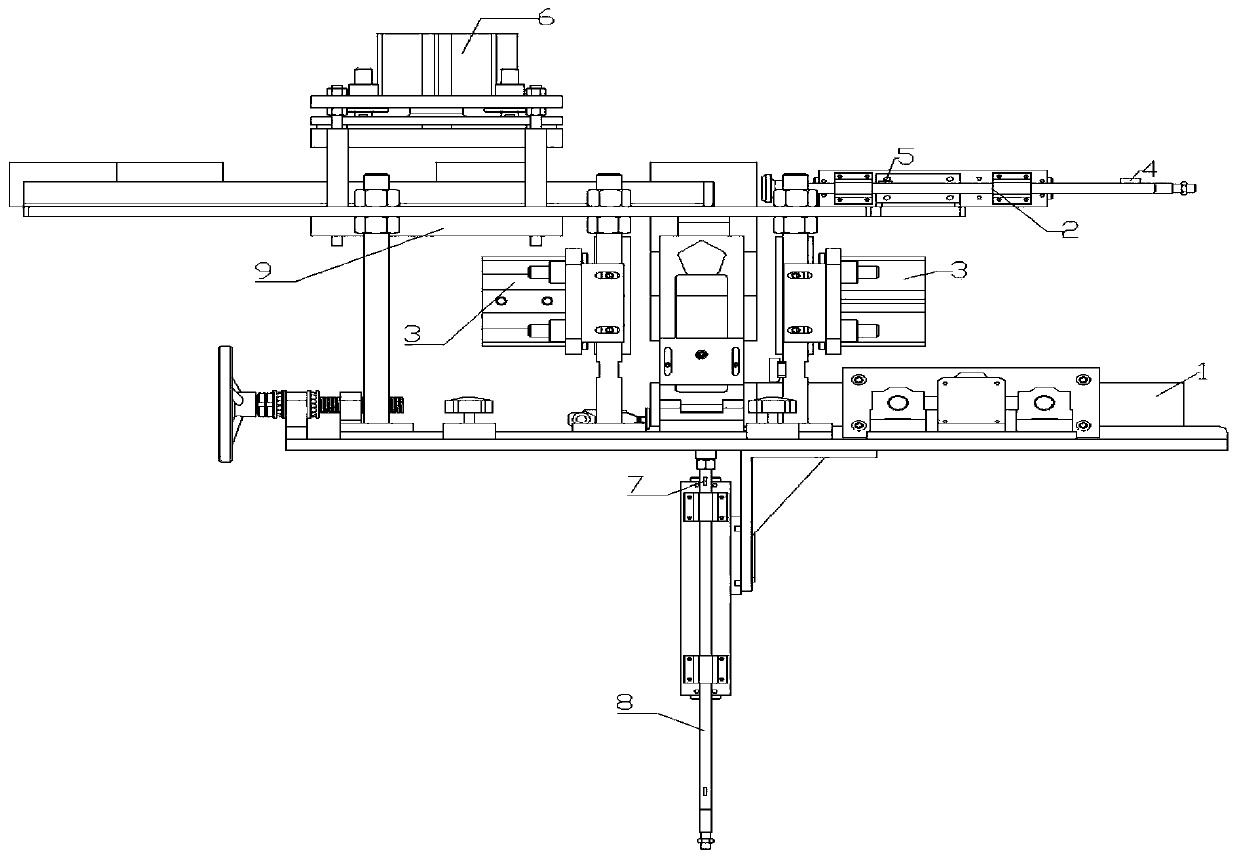

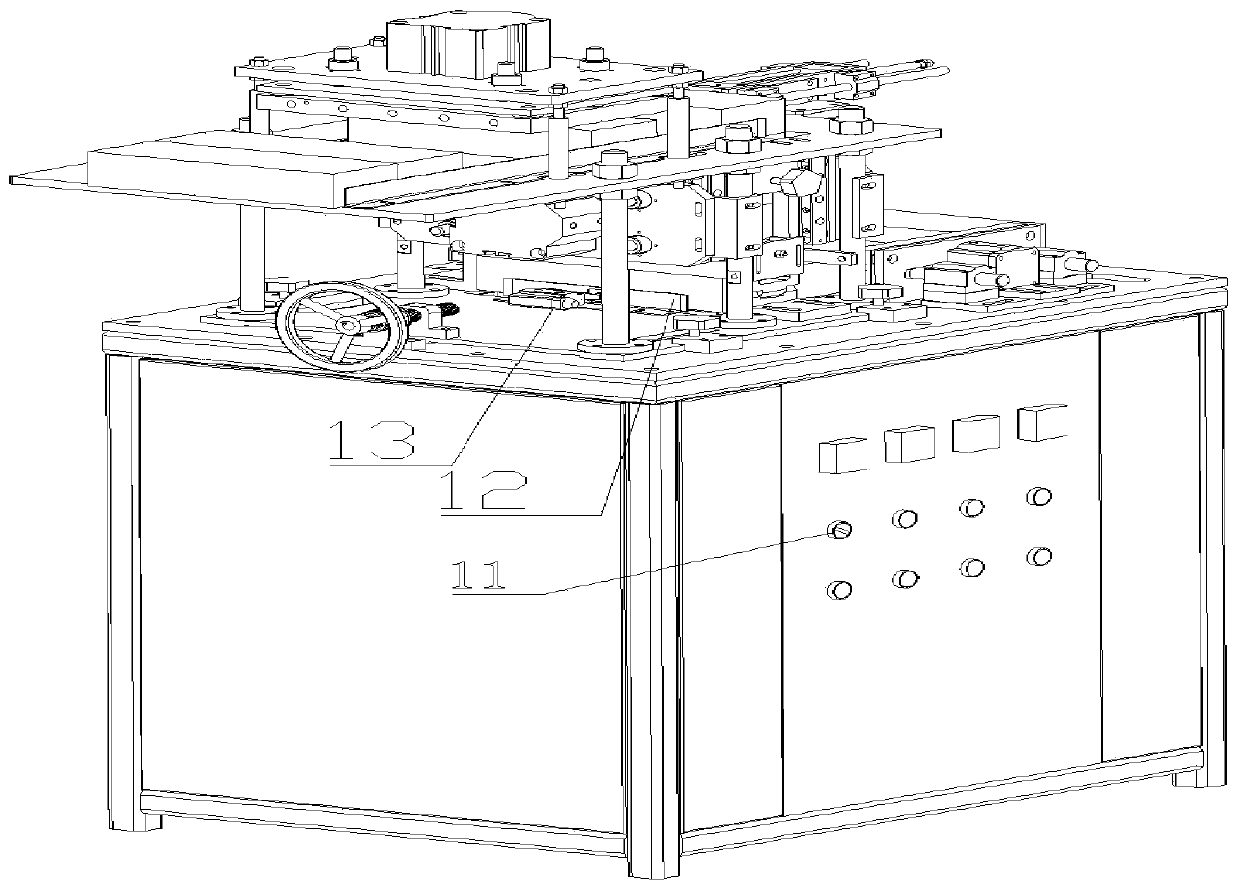

Method and equipment for removing chip

InactiveCN102240936AAchieve plastic effectImprove pass rateEdge grinding machinesEngineeringFour-slide

The invention discloses equipment for removing chip. The equipment comprises a fixed support, four sliding pieces, two rollers, two adjustment pieces, and two elastic pieces. Four sliding pieces are arranged on two opposite sides of the fixed support in a slidable manner and two sliding pieces are opposite to the other two sliding pieces. Two rollers are arranged parallel to each other at an interval; and revolving shafts at two ends of each roller are connected with two opposite sliding pieces in a rotatable manner. Two adjustment pieces pass through the fixed support and are connected with the sliding pieces at two ends of one of the rollers to adjust the positions of the sliding pieces relative to the fixed support, so that the space between the two rollers is adjusted. Two elastic pieces are clamped between the sliding pieces of the other roller and the fixed support respectively, and subjected to elastic deformation under the extrusion of the rollers so as to perform fine adjustment on the distance between two rollers. The equipment for removing the chip can ensure that the shaping and chip removal yield of a flaky workpiece can be improved. The invention also provides a method for removing the chip.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

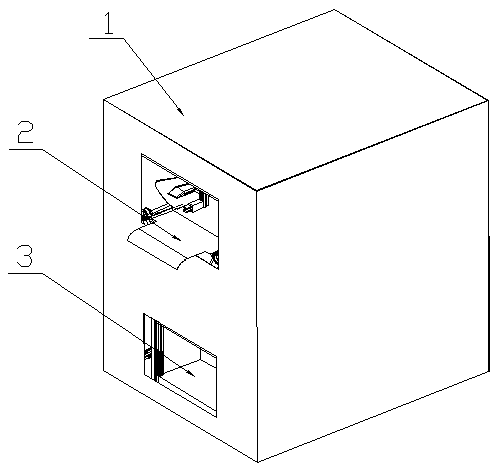

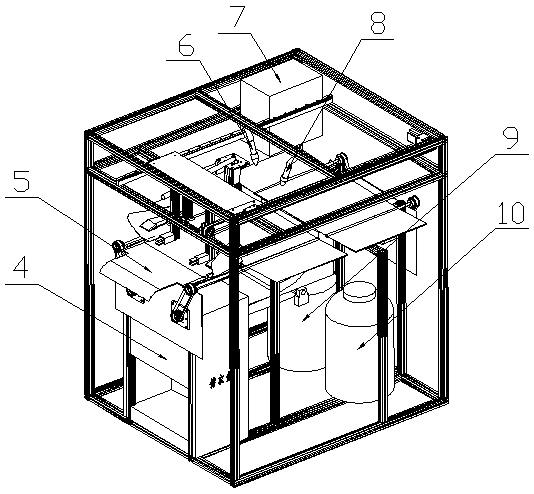

Novel automatic clothes folding machine with shaping function

PendingCN108842415AAchieve plastic effectSimple processIroning apparatusFolding thin materialsEngineeringShape function

The invention discloses a novel automatic clothes folding machine with a shaping function. The novel automatic clothes folding machine comprises a shell, a clothes inlet and a clothes outlet, whereinthe shell internally comprises a clothes entering guide device, a clothes drawing-in mechanism, a clothes folding platform, a clothes steam ironing and disinfecting mechanism, a clothes doubling mechanism, a clothes doubling sliding arc track, a clothes transportation-out conveying belt and a clothes storage box. Through combination of mechanical folding and sliding groove folding and shaping, when folded, the clothes can be shaped, the clothes only needs to be folded one time in the whole process, then the folding step is completed by using an arc-shaped shaping groove, and the aims of shaping and transportation are achieved; the three functions are integrated, the process can be simplified, time can be shortened, space can be saved, and therefore, the cost is reduced.

Owner:上海楷沃机器人科技有限公司

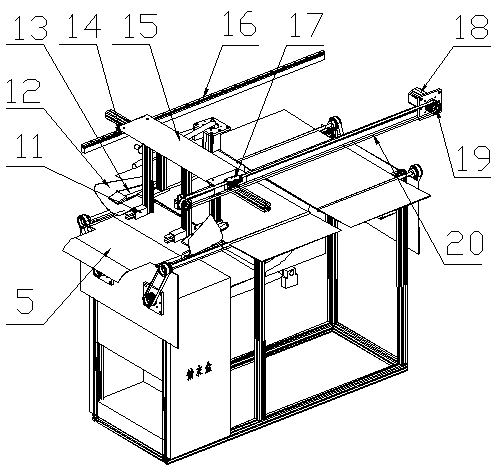

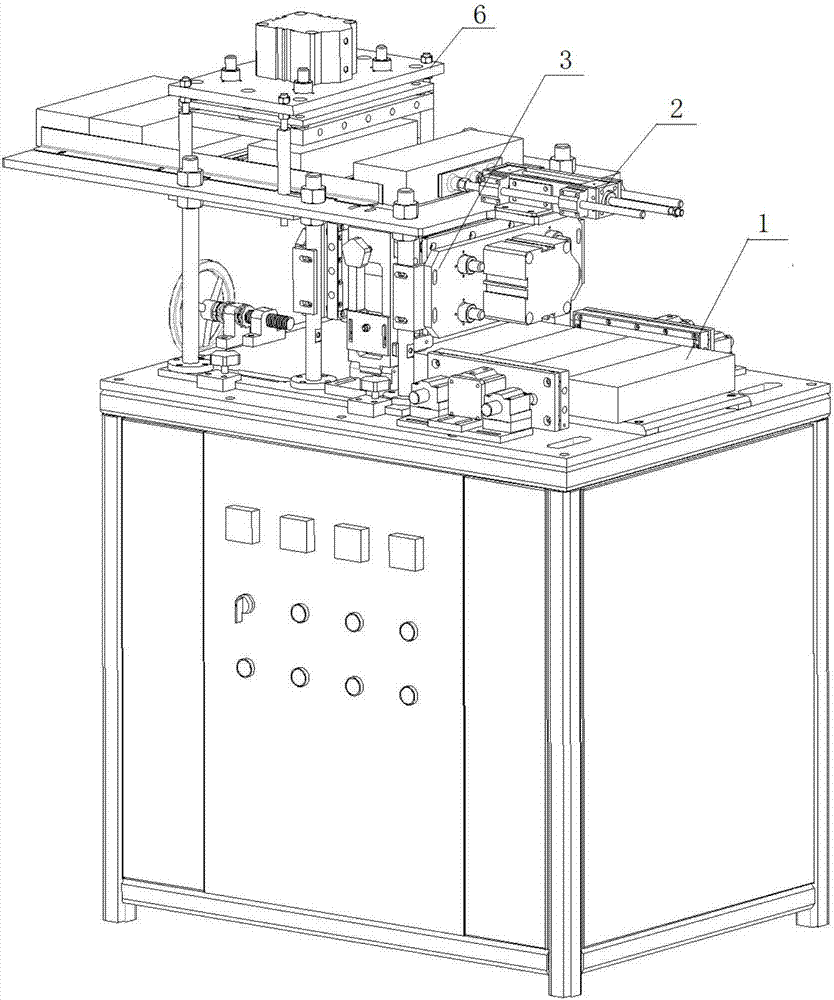

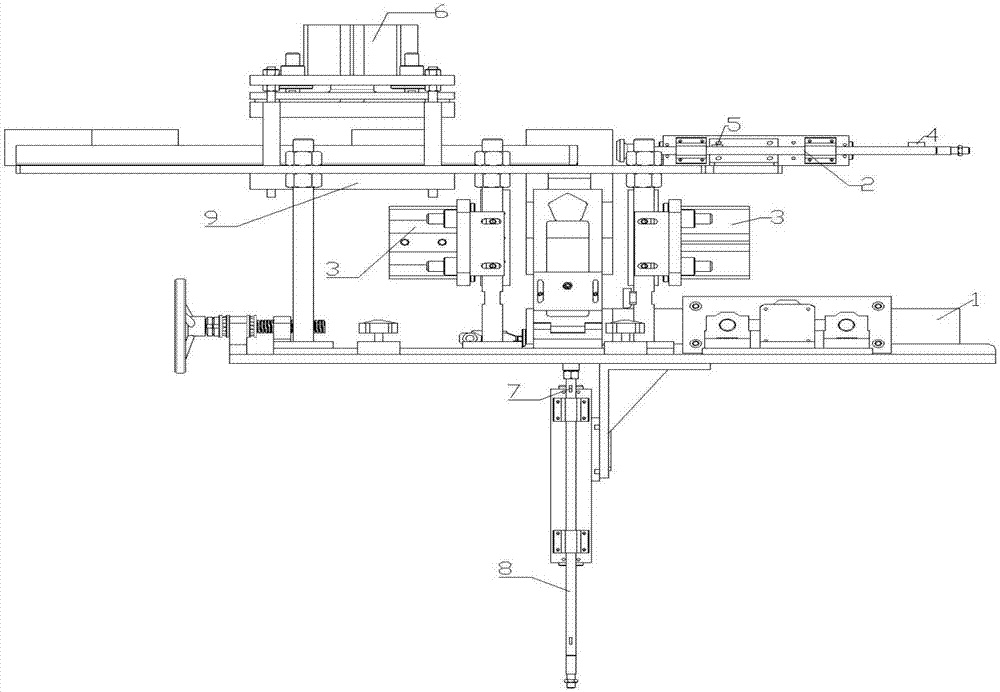

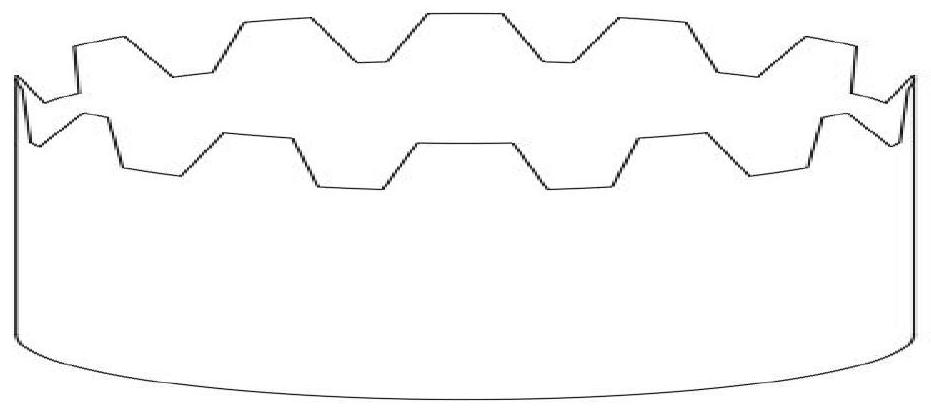

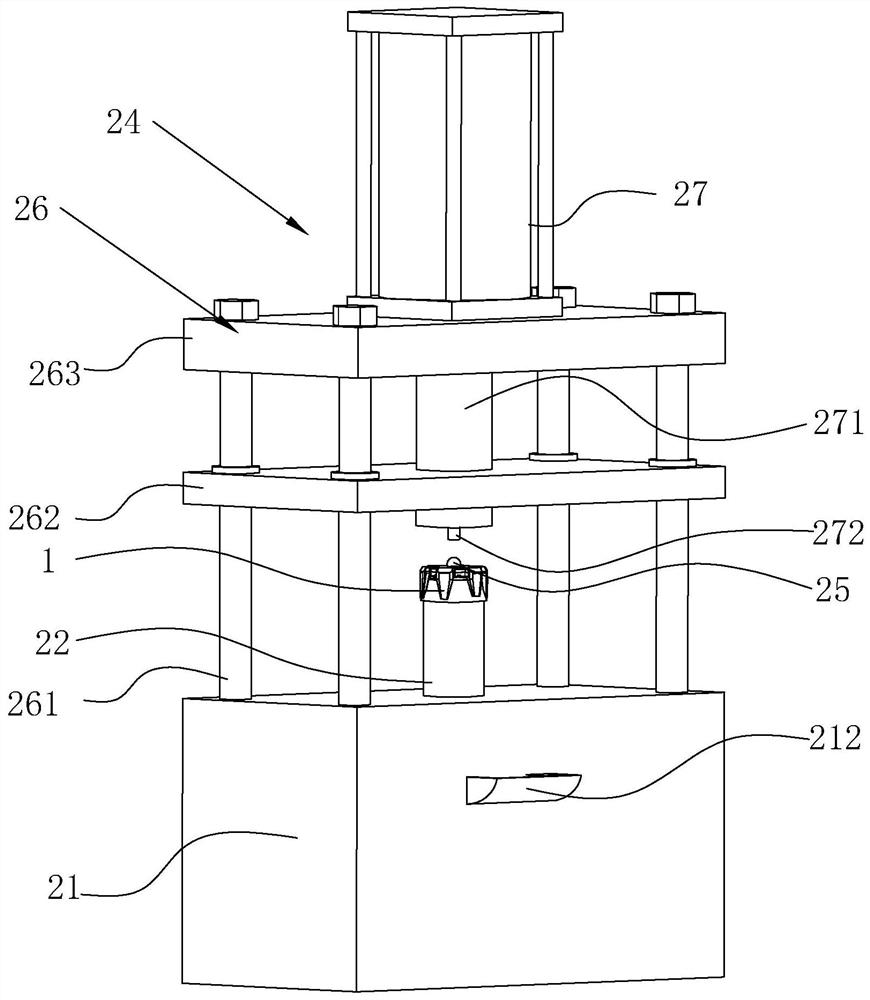

Shaping device for cylindrical flange plate after forging and working method

InactiveCN112171176AImprove efficiencyImprove qualityMetal working apparatusManufacturing engineeringFlange

The invention relates to the field of flange plate forging, in particular relates to to a shaping device for a cylindrical flange plate after forging and a working method. The shaping device comprisesa base, a supporting frame, a controller, a rotating mechanism, a repairing mechanism and a position adjusting mechanism, wherein the rotating mechanism comprises a machining table and a rotating component; the position adjusting mechanism is arranged at the top of the base so as to support the repairing mechanism to adjust the position, and the position adjusting mechanism comprises a lifting plate, a sliding component and a jacking component; the repairing mechanism comprises a bearing plate, a hammer head, a spray head, a material receiving pipe, a pushing component and a discharging component; and the rotating component, the sliding component, the jacking component, the pushing component and the discharging component are electrically connected with the controller. According to the shaping device for the cylindrical flange plate after forging and the working method, various defects on the outer wall of the flange plate can be detected in time and repaired in time, and meanwhile, most of repairing modes are automatic; and meanwhile, frequent contact of workers is not needed in the repairing process, and thus potential safety hazards are small.

Owner:含山县龙顺机械配件厂

Carton transparent shaping device used in cigarette special packaging

ActiveCN107572072AAchieve six-sided shaping effectAchieve plastic effectPackagingCartonPulp and paper industry

The invention provides a carton transparent shaping device used in cigarette special packaging. The carton transparent shaping device comprises end face shaping soldering iron and air cylinder components, a carton lifting air cylinder, side face shaping soldering iron and prolusion air cylinder components, a bag pushing air cylinder, an upper face shaping soldering iron and air cylinder componentand a carton bottom shaping soldering iron. The end face shaping soldering iron and air cylinder components are located on the two sides of a carton conveying channel. A supporting baffle connected with the carton lifting air cylinder is arranged at the tail end of the carton conveying channel. Two vertical carton ascending channels composed of carton baffles are arranged above the supporting baffle. The side face shaping soldering iron and prolusion air cylinder components are arranged on the two sides of the carton ascending channels. The bag pushing air cylinder and a carton transverse movement channel are arranged on the two sides of the top ends of the carton ascending channels correspondingly. The upper face shaping soldering iron and air cylinder component and the carton bottom shaping soldering iron are arranged on the two sides of the carton transverse movement channel correspondingly. The carton transparent shaping device can solve the quality defect problem that wrinkles aregenerated to transparent paper due to uneven surfaces of carton clamp plate materials.

Owner:HUBEI CHINA TOBACCO IND

Equipment cabin door plate shaping device

The invention relates to the technical field of door plate shaping, and discloses an equipment cabin door plate shaping device. The device comprises a workbench, a clamping mechanism and a drawing mechanism, wherein the clamping mechanism is arranged on the workbench, is used for fixing a door plate onto the workbench, and comprises a clamping assembly slidably connected with the workbench; and the drawing mechanism is used for sucking the door plate and pulling the door plate to move and comprises a supporting device fixedly connected with the workbench, an air pressure adjusting assembly is slidably connected to the supporting device, and a suction device is arranged at the end, close to the workbench, of the air pressure adjusting assembly. According to the equipment cabin door plate shaping device, the suction device makes contact with the door plate, so that concave and convex deformation of the door plate can be well adjusted and recovered; and moreover, damage to the door plate is small due to the connection of the suction device and the door plate, scratching of a paint surface on the surface of the door plate is avoided, and the door plate can be better protected.

Owner:山东奥扬新能源科技股份有限公司

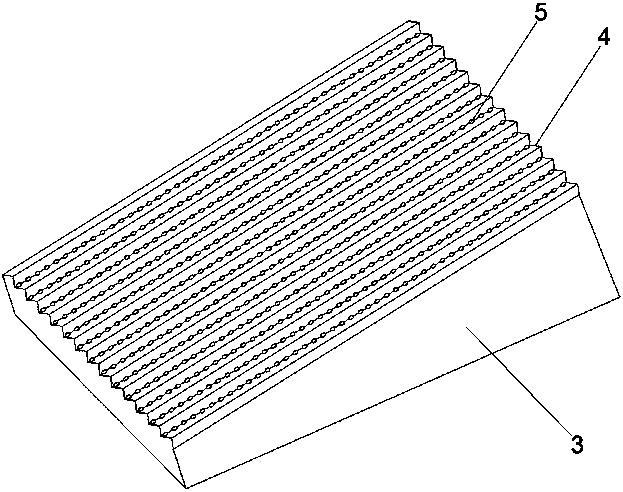

Porcelainized aluminum wear-resistant brick and preparation method thereof

InactiveCN107840638AHigh mechanical strengthImprove wear resistanceCeramic materials productionClaywaresBrickPhosphate

The invention belongs to the technical field of refractory matters, and particularly relates to a porcelainized aluminum wear-resistant brick and a preparation method thereof, which mainly solve the technical problem that an existing refractory matter is poor in wear-resisting property. The invention has the technical scheme that the porcelainized aluminum wear-resistant brick is prepared from a mixed batch and a binding agent, wherein the mixed batch is prepared from the following raw materials in percentage by weight: 50 to 70 percent of aluminum oxide porcelainized aluminum particle, 10 to20 percent of silicon carbide particle, 10 to 30 percent of bauxite clinker, and 3 to 11 percent of Suzhou clay; the binding agent is a mixture of solid aluminum dihydrogen phosphate and lignosulfite;the additive amount of the binding agent is 3 to 8 percent of the total weight of the mixed batch. The preparation method of the porcelainized aluminum wear-resistant brick comprises the following steps of (1) preparing an aluminum oxide porcelainized aluminum raw material; (2) preparing the binding agent; (3) mixing and milling the raw material; (4) forming to make a blank; (5) drying; (6) firing; (7) cooling to obtain a finished product. The porcelainized aluminum wear-resistant brick provided by the invention has the advantages of high wear resistance, long service life, capability of low-temperature firing, and the like.

Owner:吕梁耀金道冶金材料工程技术有限公司

Floating block of hub shaping die

Owner:宁波路威汽车轮业有限公司

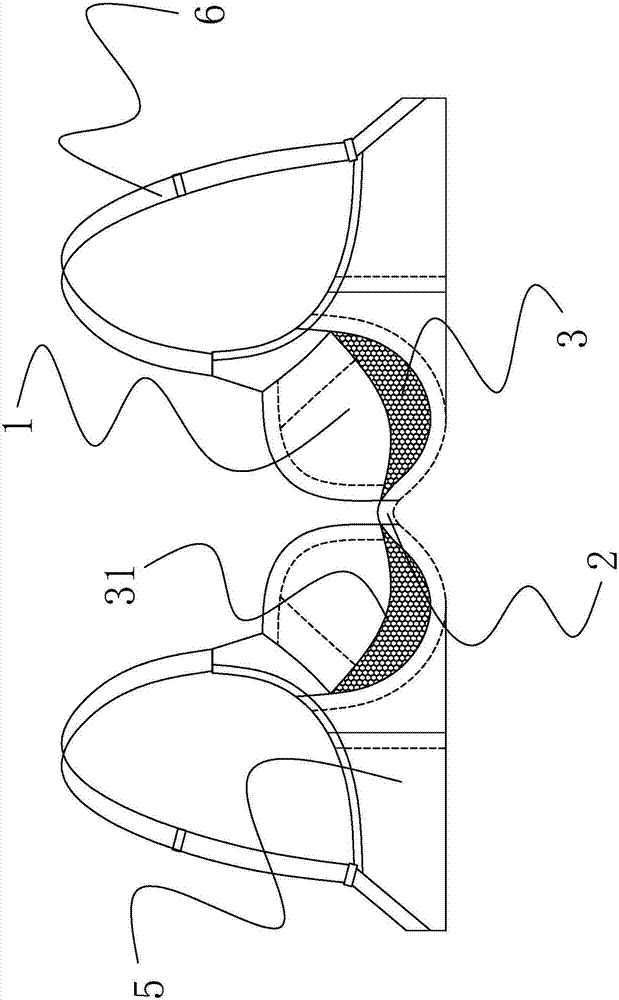

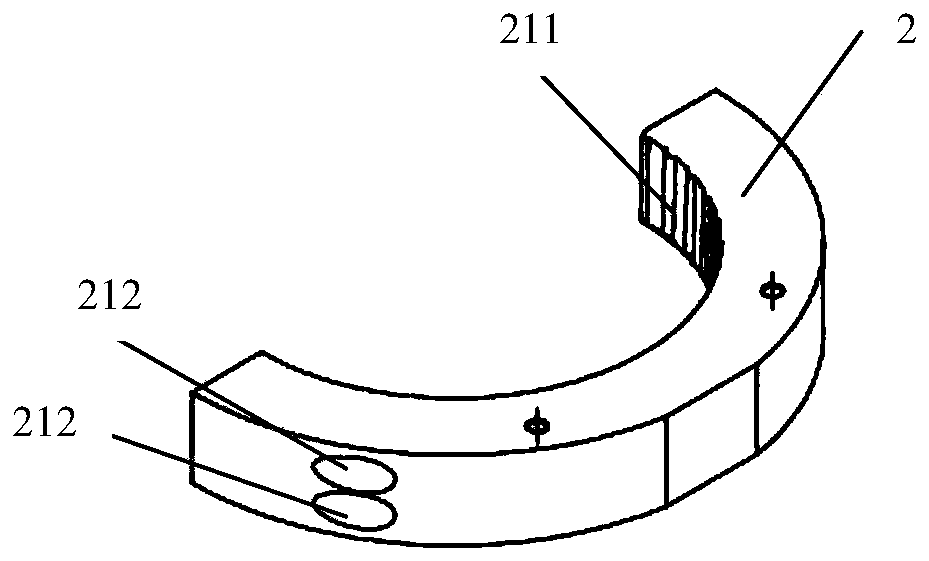

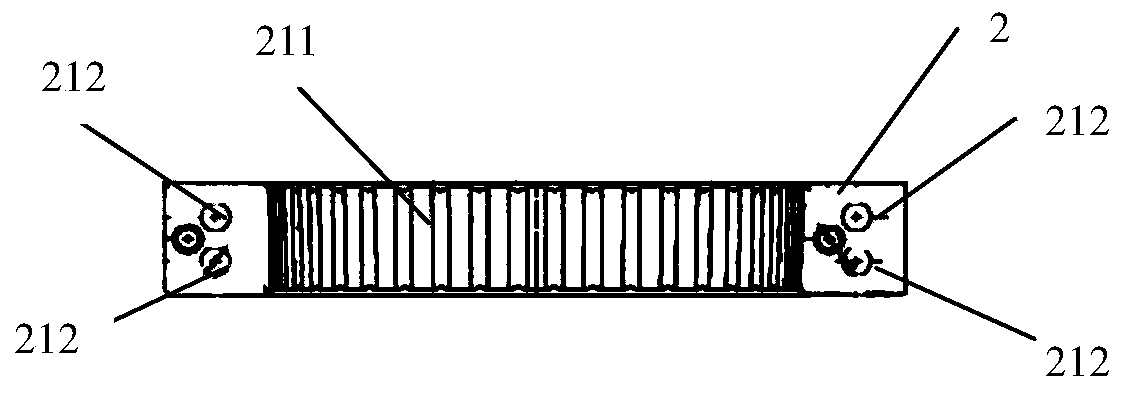

Bralette

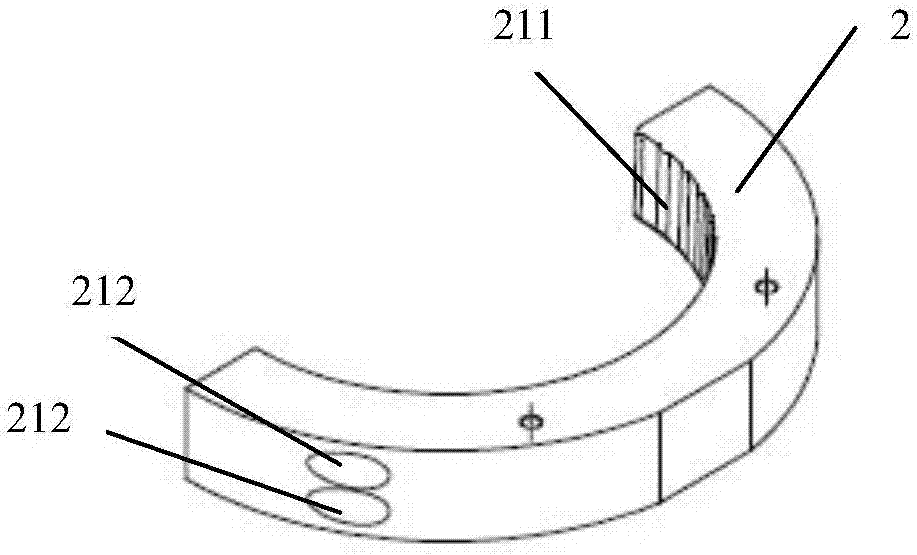

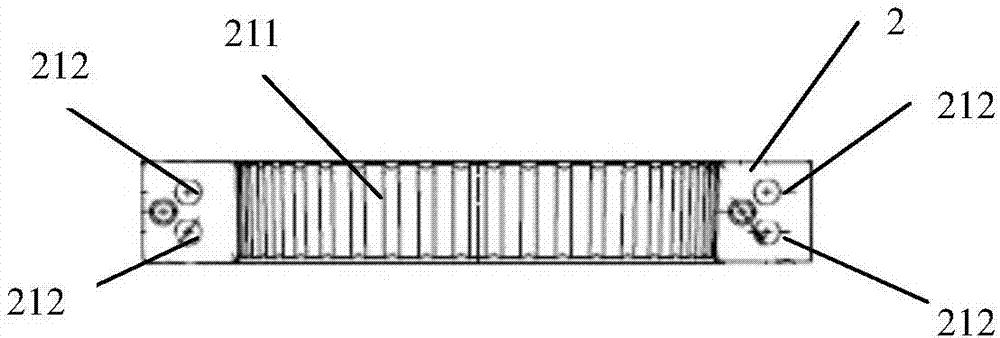

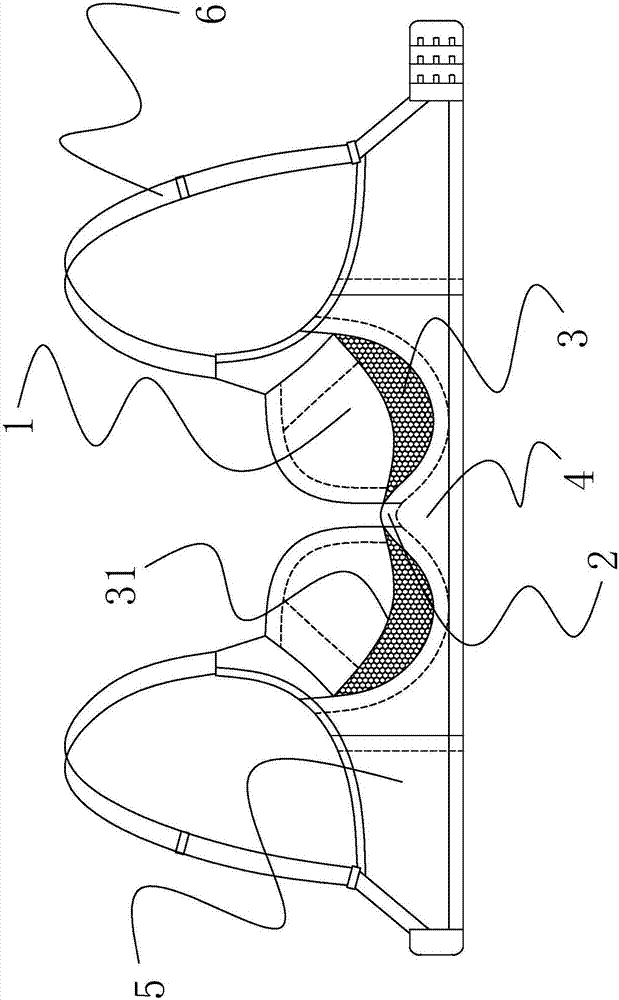

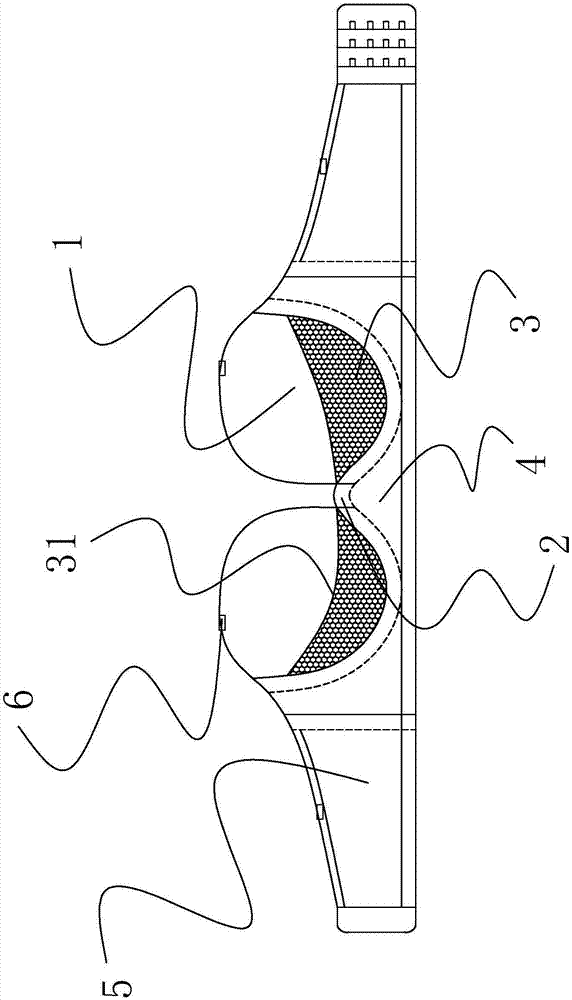

InactiveCN107048494AWith rebound liftHas the effect of plastic gatheringBrassieresEngineeringMechanical engineering

The invention discloses a bra without rims, which comprises two symmetrically arranged cups and a heart part connecting the two cups, and a support pad is arranged on the inner surface of the concave inner side of the cup, and the support pad The bottom edge is spliced together with the lower edge of the cup, and a V-shaped cavity is formed between the support pad and the inner surface of the cup, and the support pad is made of elastic fabric. In the present invention, a support pad with a certain elasticity is provided on the inner surface of the cup, and a cavity with a V-shaped cross section is formed between the support pad and the lower part of the cup, so that the breast can be rebounded and lifted after wearing, and has plasticity. At the same time, the coverage area of the elastic supporting pad is much larger than that of the steel ring, so that it has the same supporting strength and plastic effect as the steel ring or even better than the steel ring.

Owner:广东新怡内衣科技有限公司 +1

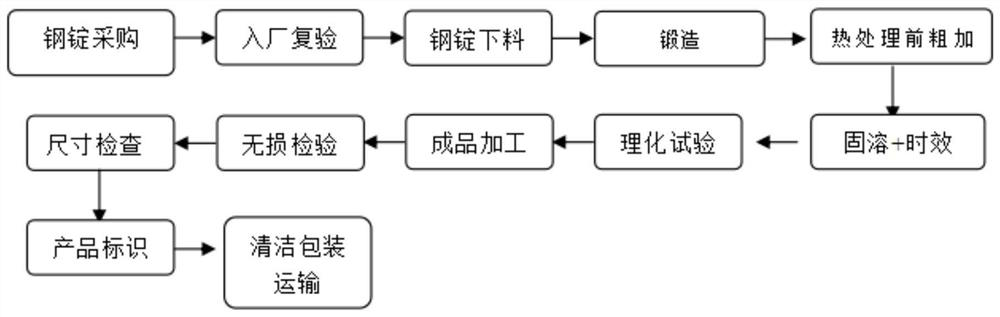

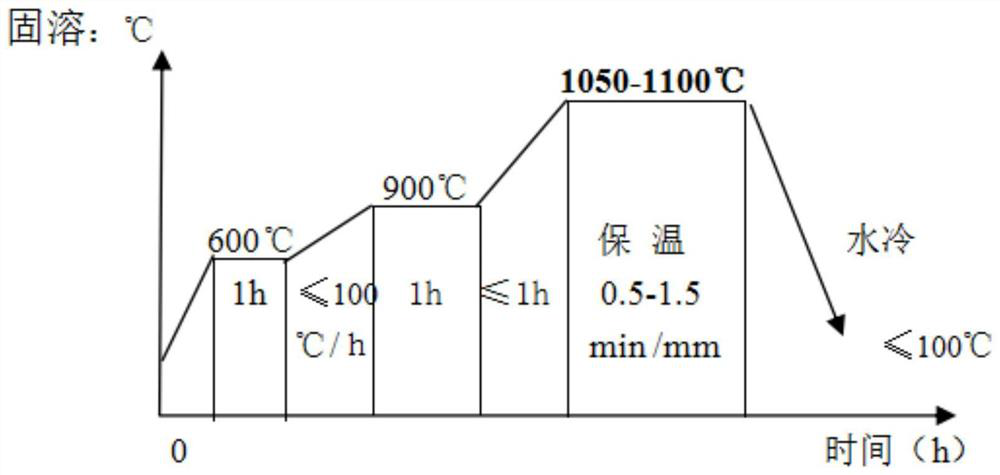

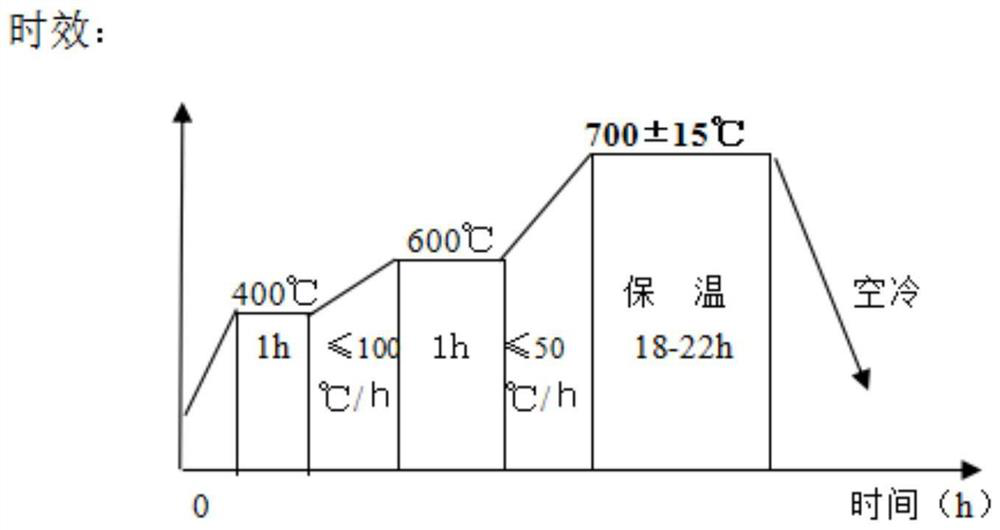

Manufacturing method of reactor internals middle ring

PendingCN114523065AReduce consumptionReduce intergranular precipitationNuclear energy generationFurnace typesPunchingIngot

The invention discloses a method for manufacturing a reactor internal middle ring, which comprises the following steps of: a blank manufacturing stage: charging a raw material ingot into a furnace, heating to a forging temperature, repeatedly forging, upsetting and drawing out for multiple times, and punching by using a punch to obtain a blank meeting the requirement; a forming stage: chambering the blank by using a chambering tool to obtain a reactor internal middle ring blank forge piece; and in the heat treatment stage, the reactor internal middle ring blank forge piece is placed in a heat treatment furnace, proper technological parameters are controlled, and after the forge piece is evenly heated, the forge piece is taken out of the furnace and subjected to water cooling. According to the manufacturing method of the reactor internal middle ring, through optimized forging process control and heat treatment, the forging defects such as cracks and looseness can be effectively avoided, uniform and fine second-phase particles are mainly separated out in crystals, the situation that the second phase is separated out along the crystals is reduced, and the material obtains good comprehensive performance.

Owner:上海新闵重型锻造有限公司

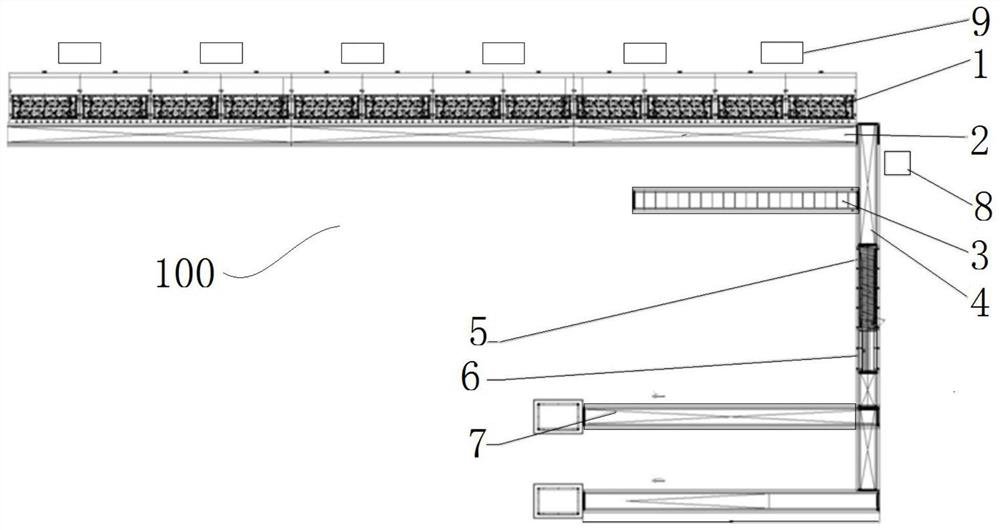

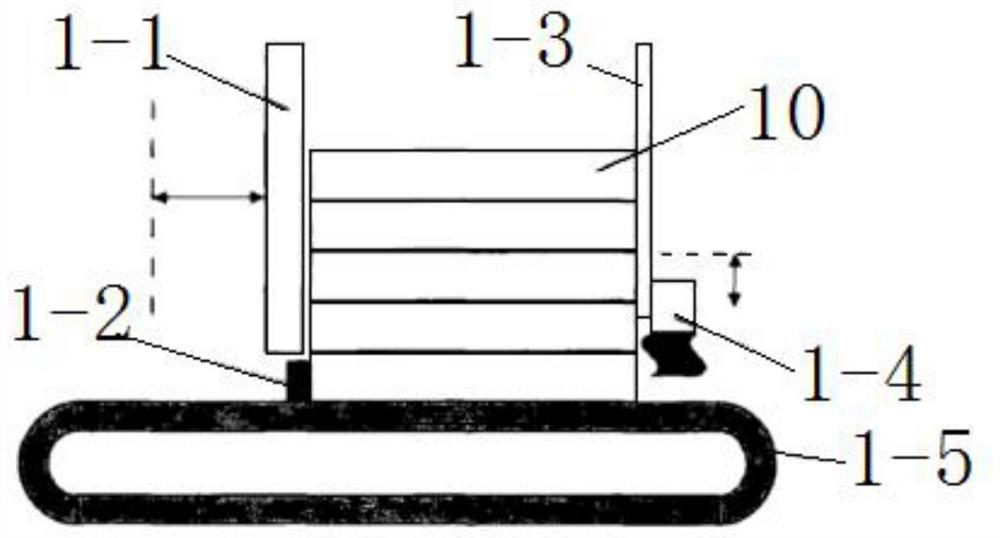

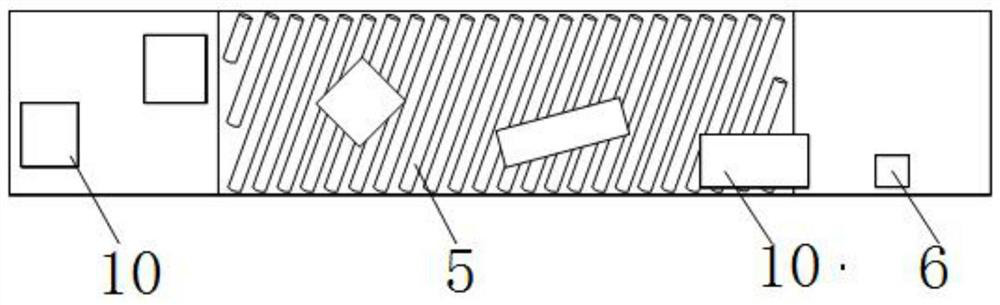

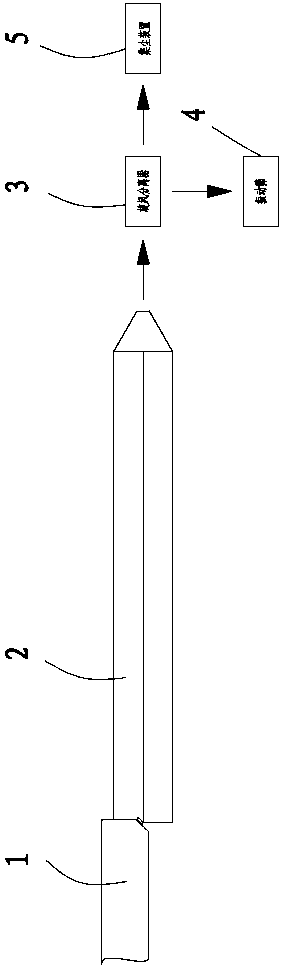

Vertical sorting system for special-shaped cigarettes

PendingCN113560216AAchieve plastic effectHigh control precisionConveyorsControl devices for conveyorsControl systemStructural engineering

The invention discloses a vertical sorting system for special-shaped cigarettes. The system comprises a main line belt, a plurality of special-shaped cigarette vertical sorting machines are evenly arranged at one side of the main line belt, a cigarette posture steering belt perpendicular to the main line belt is arranged at the tail end of the main line belt, and an side reshaping roller and a laser coding machine are sequentially arranged at the tail end of the cigarette posture steering belt. A discharging opening belt line is arranged at the tail end of the laser coding machine, and the special-shaped cigarette vertical sorting machines are connected with a control system. The vertical sorting system for the special-shaped cigarettes is wide in sorting range and high in sorting efficiency.

Owner:HEBEI UNIV OF TECH

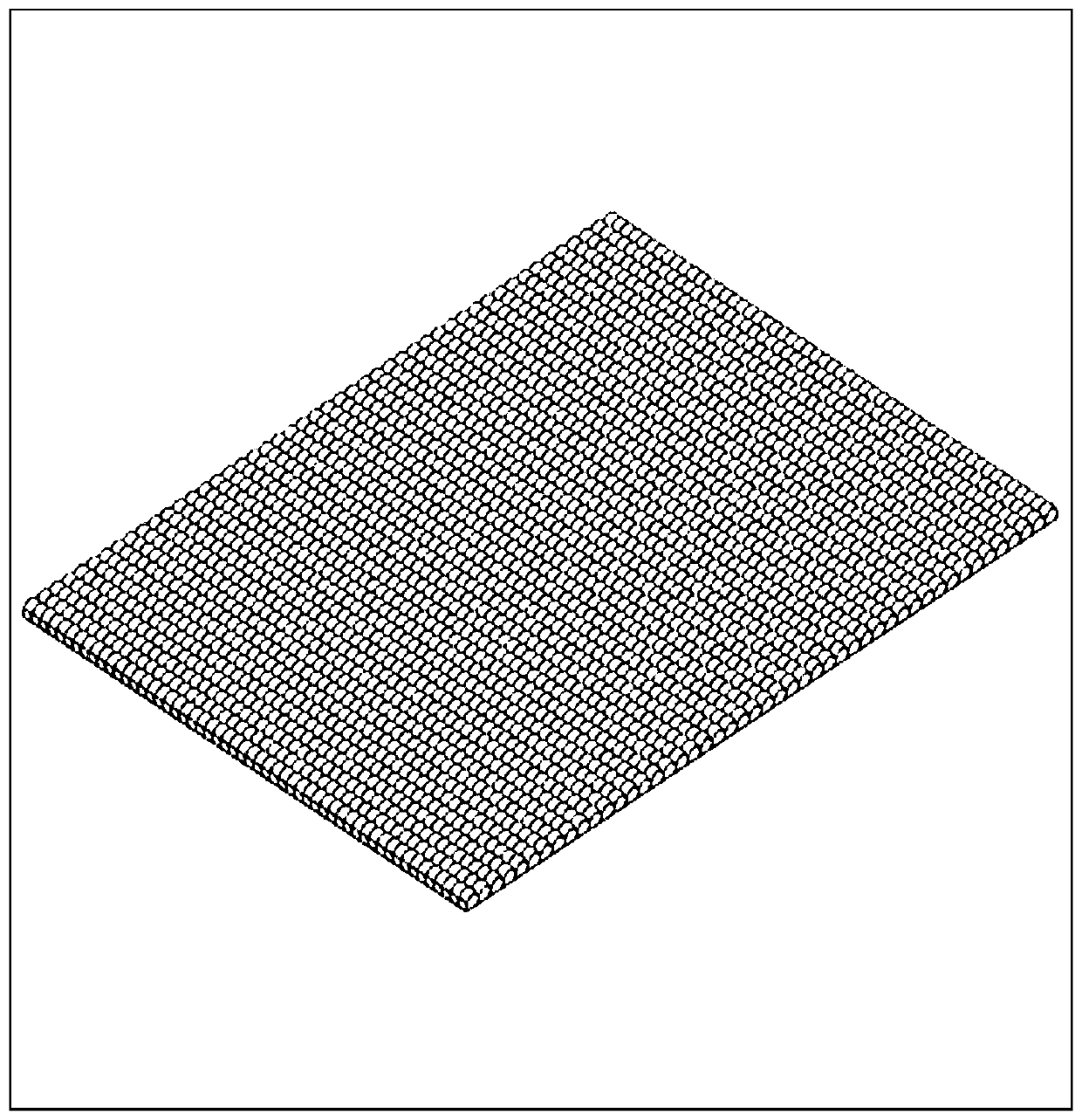

Preparation method of tricholoma matsutake gardening culture medium block

InactiveCN112335489AReduce economic lossAchieve plastic effectBiocideMacromolecular adhesive additivesBiotechnologyCompression molding

The invention discloses a preparation method of a tricholoma matsutake gardening culture medium block, and relates to the technical field of wood-plastic plate processing. The preparation method of the tricholoma matsutake gardening culture medium block comprises the eight steps of raw material preparation, stacking fermentation, paving disinfection, layered paving, compression molding, slitting,gluing and drying molding. According to the preparation method of the tricholoma matsutake gardening cultivation medium block, the prepared tricholoma matsutake gardening cultivation medium block canbe directly applied to gardening cultivation, and hole grooves with equal intervals and sizes are reserved, so that a gardening user can conveniently plant tricholoma matsutake strains; and meanwhile,the situation that follow-up growth of the tricholoma matsutake is limited due to the fact that the distances of manual grooves are different is avoided, the periphery of the medium block is glued toachieve the plastic effect, the possibility that the medium block is damaged due to collision in the transportation process can be reduced, various foam materials do not need to be used for protecting the medium block, and the transportation cost is reduced.

Owner:HAINAN UNIVERSITY

Floating block of hub shaping die

Owner:宁波路威汽车轮业有限公司

Gomphrena globosa shaping agent and using method thereof

The invention discloses a gomphrena globosa shaping agent and a using method thereof. The gomphrena globosa shaping agent is prepared from 2-chloro-N(2-ethyl-6-methylphenyl)-N-(2-methoxyl-1-methyl ethyl)acetamide, N, N-bis (phosphonomethyl)glycine, and sucrose by compatibility of medicines, the weight ratio of the three components is (3.0 to 4.0) to (1. 0 to 2.0) to (4.0 to 6.0), and the optimum selection ratio is 3.5 to 1.5 to 5.0. The three components are calculated by weight-to-mass ratio in 100% purity. The gomphrena globosa shaping agent is diluted to spray immediately according to concentration of 100 to 200mg.L<-1> when using. Operation should be conducted in cloudy or sunny evenings, no rain are guaranteed and no artificial irrigation are needed within 24 hours after spraying. After 24 hours, water fertilizer is conducted for 1 time, hereafter conventional fertilizer and water management and pest control are conducted. A dosage form of the preparation is stable, the operation is simple, the use cost is low, the shaping effect is remarkable, the components among the preparation are synergistic, and the dosage form of the preparation is a good gomphrena globosa shaping agent.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A carton transparent shaping device used in special cigarette packaging

ActiveCN107572072BAchieve six-sided shaping effectAchieve plastic effectPackagingCartonPulp and paper industry

The invention provides a carton transparent shaping device used in cigarette special packaging. The carton transparent shaping device comprises end face shaping soldering iron and air cylinder components, a carton lifting air cylinder, side face shaping soldering iron and prolusion air cylinder components, a bag pushing air cylinder, an upper face shaping soldering iron and air cylinder componentand a carton bottom shaping soldering iron. The end face shaping soldering iron and air cylinder components are located on the two sides of a carton conveying channel. A supporting baffle connected with the carton lifting air cylinder is arranged at the tail end of the carton conveying channel. Two vertical carton ascending channels composed of carton baffles are arranged above the supporting baffle. The side face shaping soldering iron and prolusion air cylinder components are arranged on the two sides of the carton ascending channels. The bag pushing air cylinder and a carton transverse movement channel are arranged on the two sides of the top ends of the carton ascending channels correspondingly. The upper face shaping soldering iron and air cylinder component and the carton bottom shaping soldering iron are arranged on the two sides of the carton transverse movement channel correspondingly. The carton transparent shaping device can solve the quality defect problem that wrinkles aregenerated to transparent paper due to uneven surfaces of carton clamp plate materials.

Owner:HUBEI CHINA TOBACCO IND

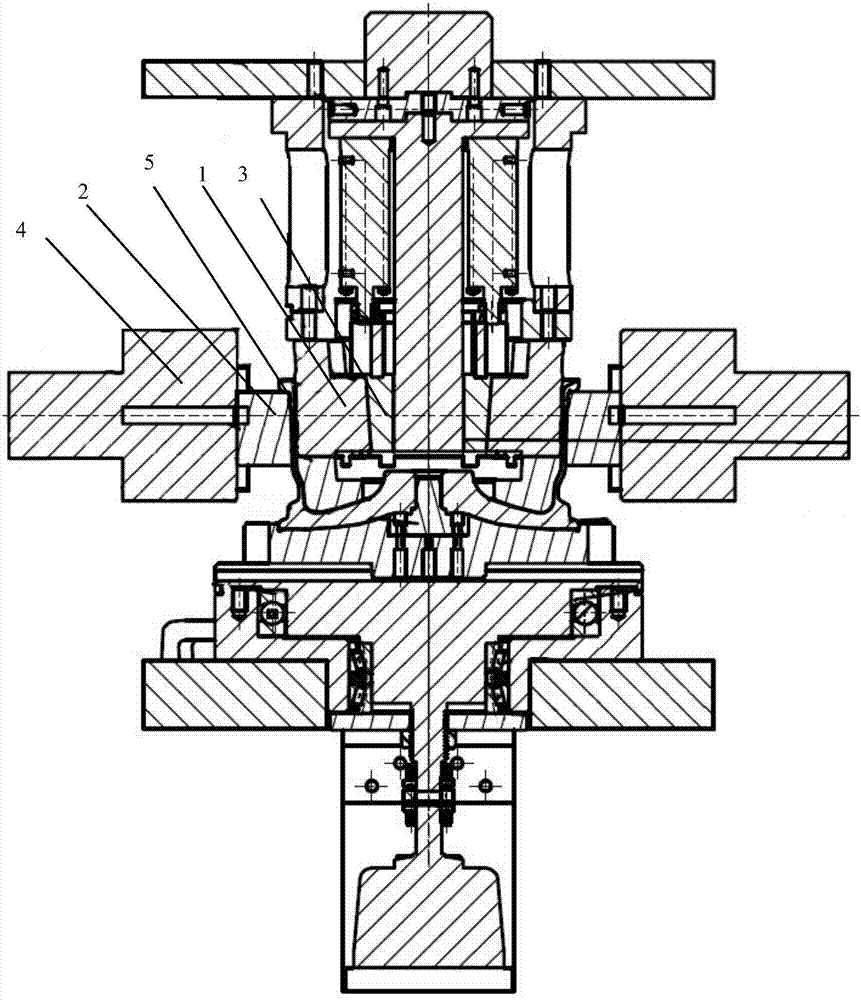

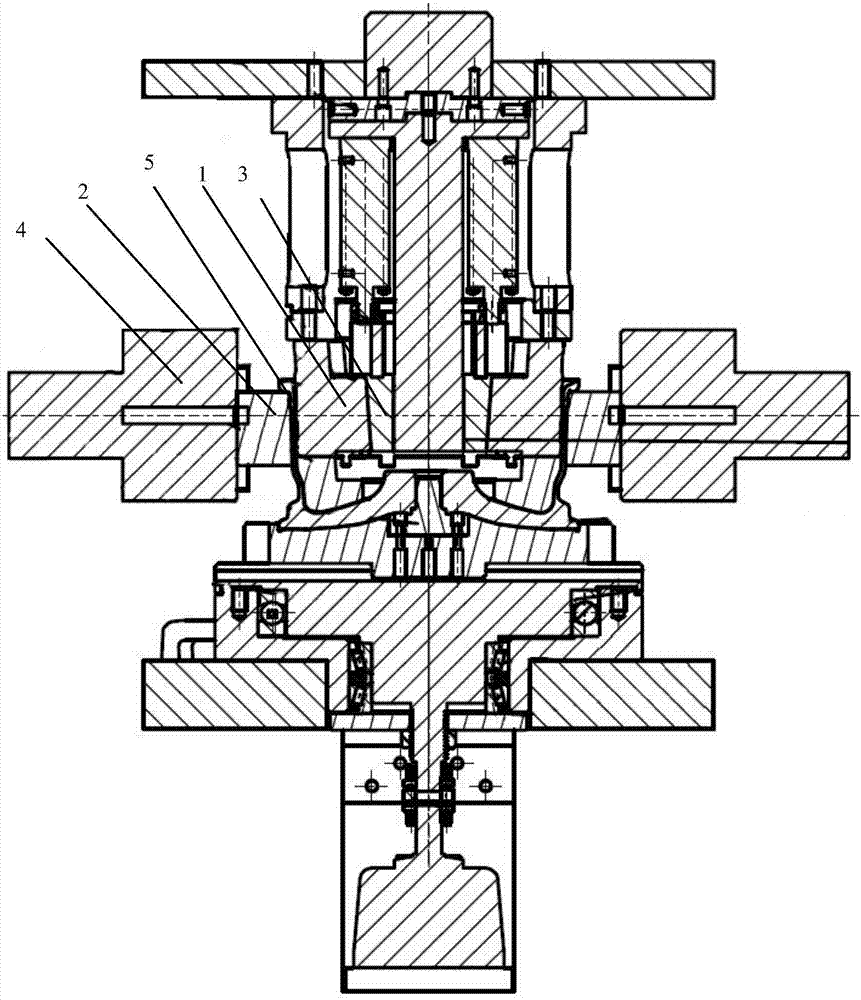

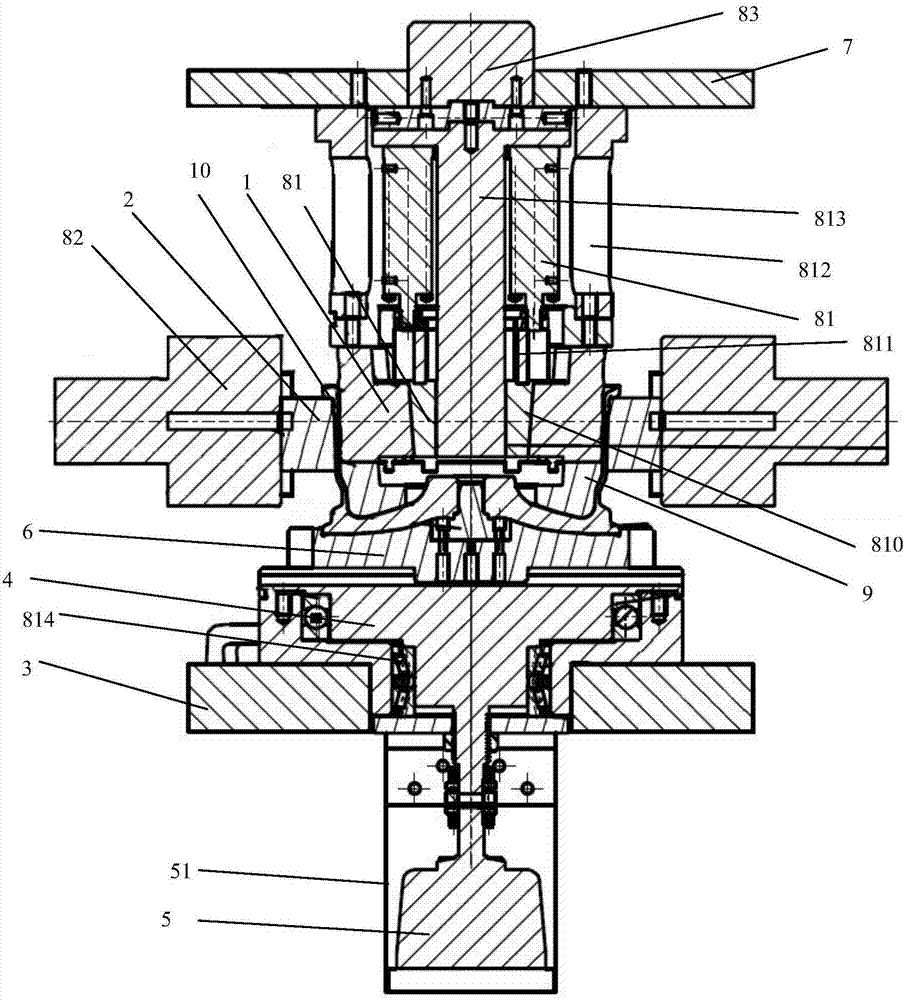

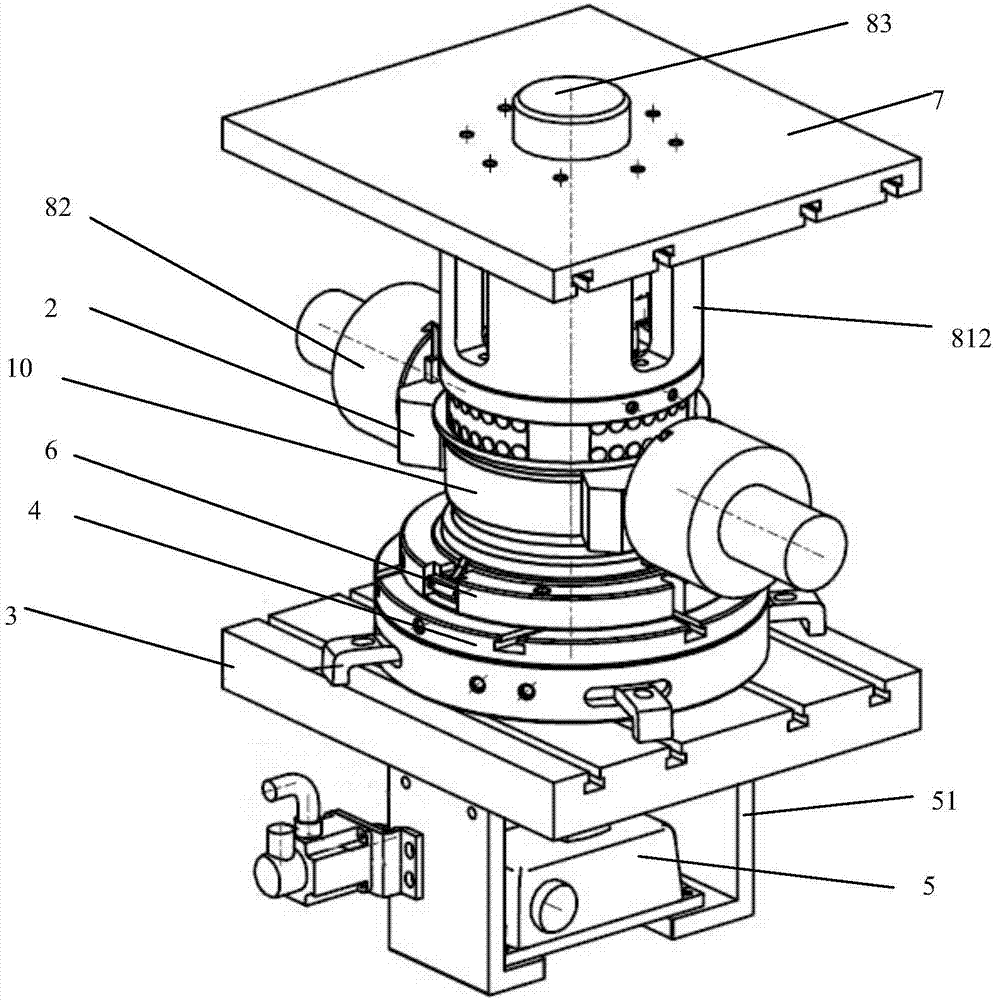

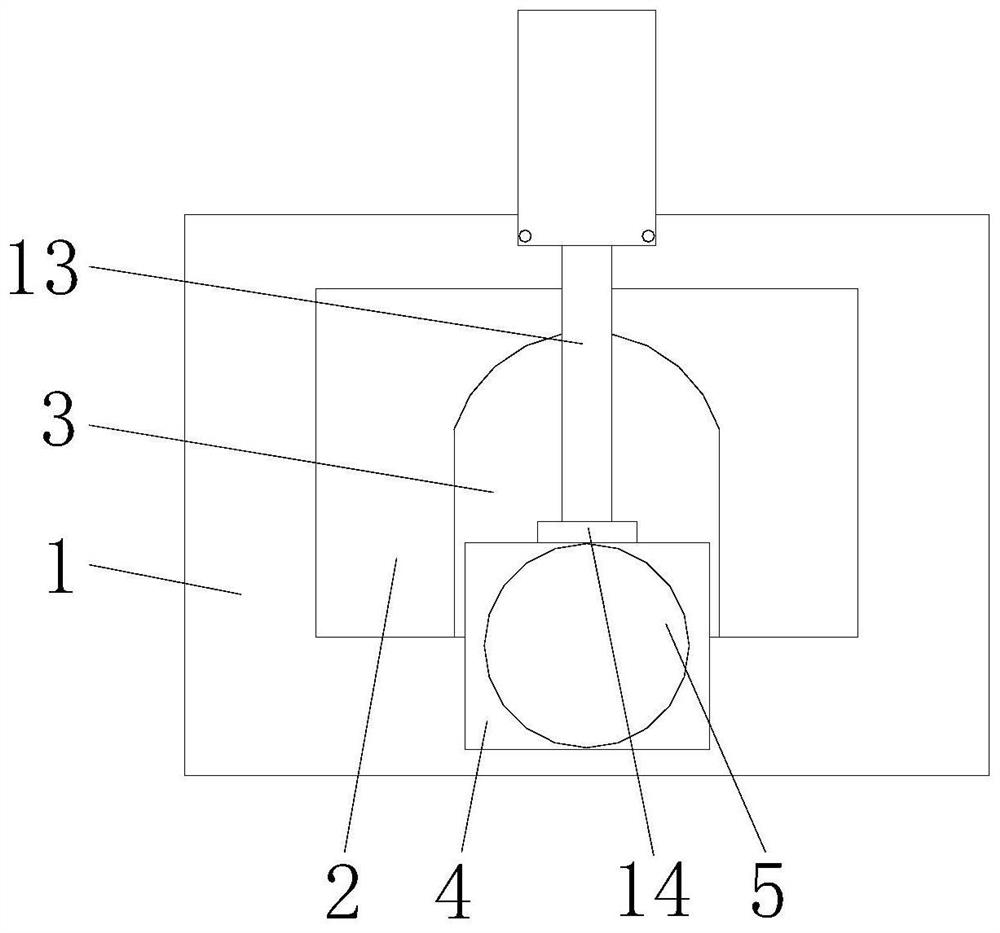

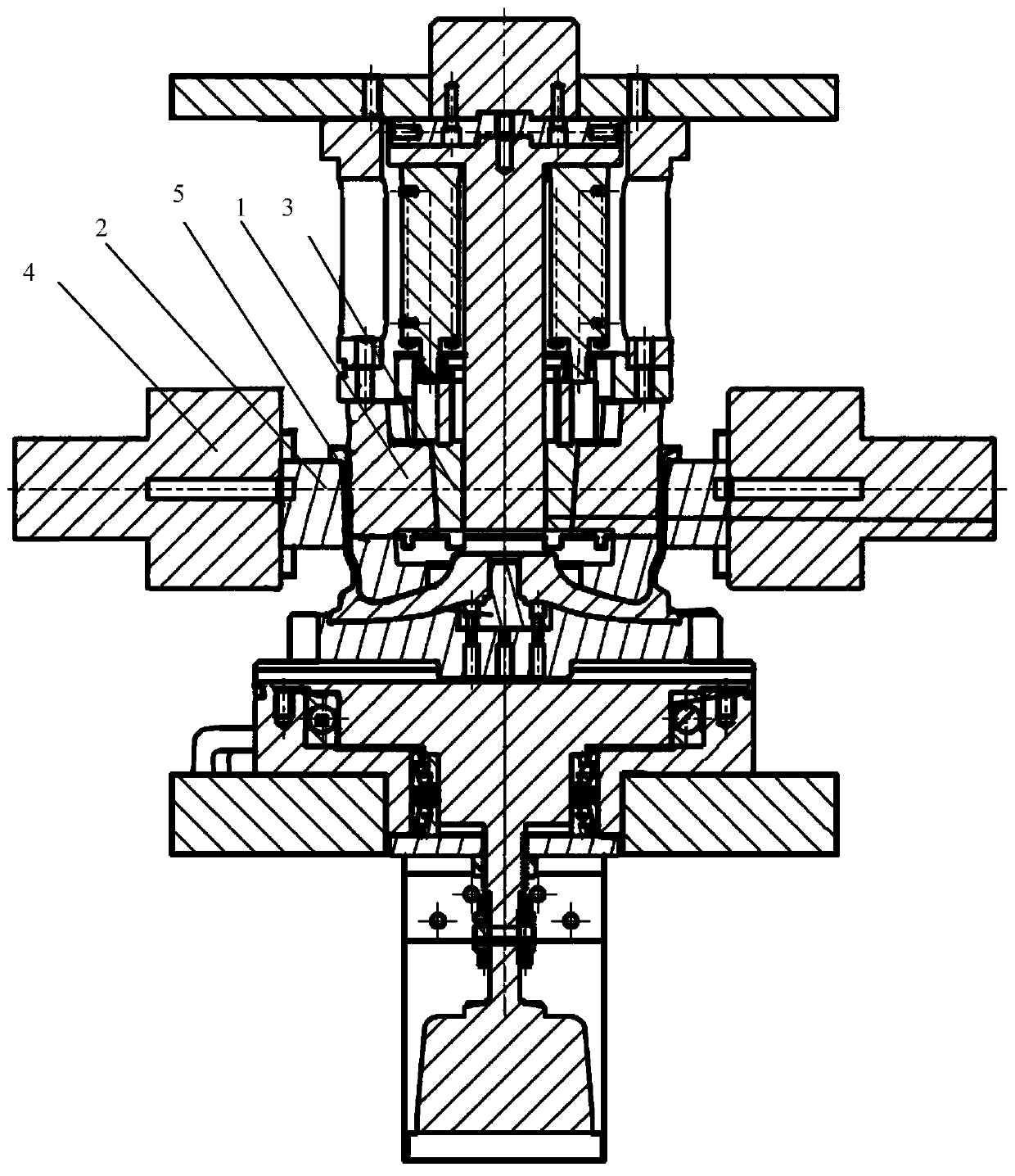

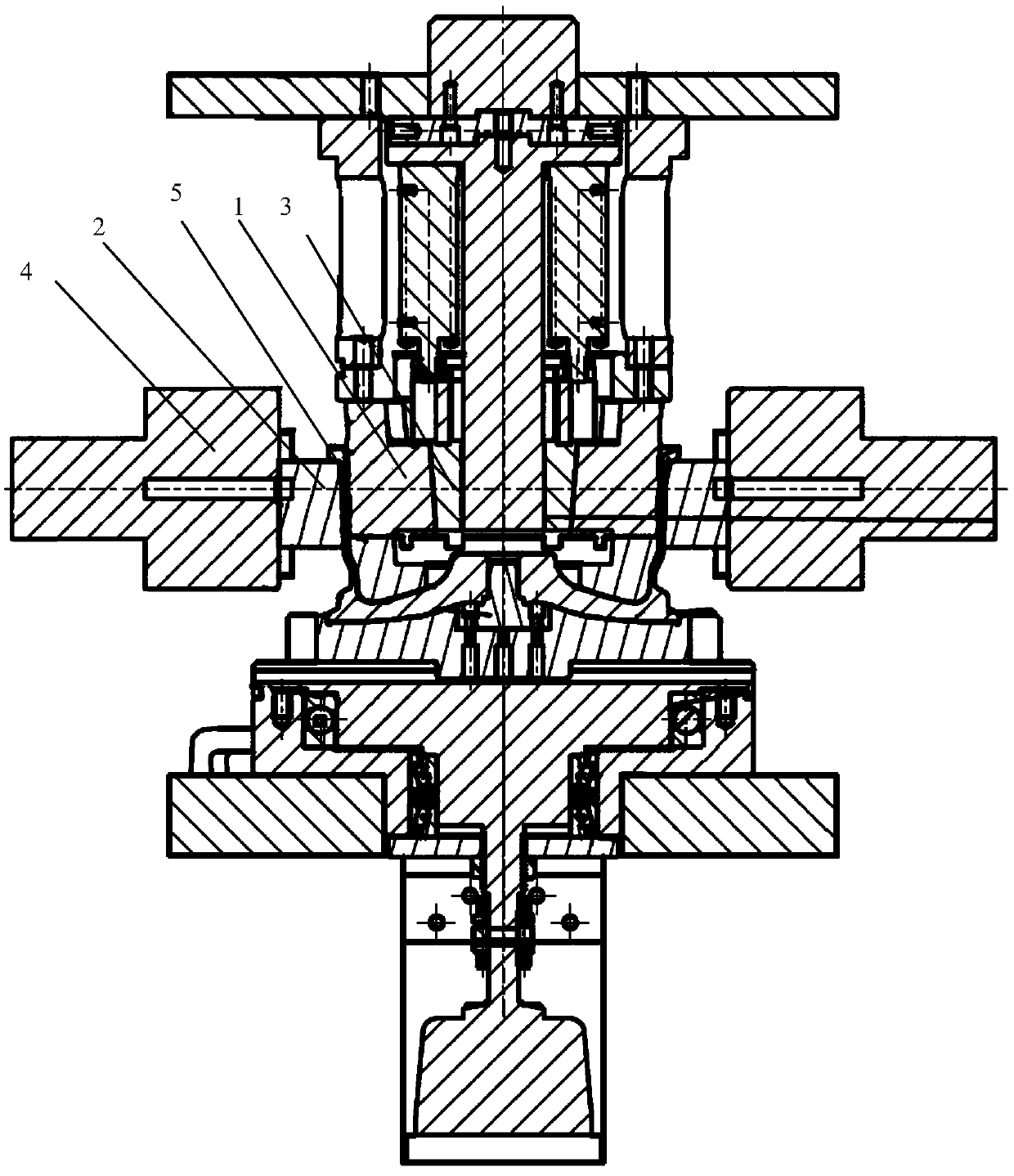

Hub shaping mold

The invention discloses a hub shaping mold. The hub shaping mold comprises a lower workbench, multiple inner supporting pieces and multiple outer pressing pieces. A rotary disc is arranged on the lower workbench. Mold cores are fixed to the rotary disc, the upper surface of the lower mold core is matched with the lower surface of a standard hub, and clamping jaws are arranged on the lower mold core. An upper workbench is located above the lower workbench, multiple hydraulic oil cylinders are arranged below the upper workbench, pressing blocks are fixed to piston rods of the multiple hydraulic oil cylinders, push block grooves are formed along the sides, towards the inner supporting pieces, of the pressing blocks, the push block grooves penetrate the lower surfaces from the upper surfaces of the pressing blocks, and vertical motion of the piston rods is converted into horizontal motion of the inner supporting pieces through the push block grooves and push blocks. The lower surface of the upper mold core is matched with the upper surface of the standard hub, and the lower ends of the inner supporting pieces abut against the upper mold core. The hub is clamped by the dot-shaped inner supporting pieces and the tooth-shaped outer pressing pieces or the dot-shaped outer pressing pieces jointly, the hub suffers from pressure of the inner supporting pieces and the outer pressing pieces at deformation positions, and therefore the shaping effect is achieved.

Owner:宁波路威汽车轮业有限公司

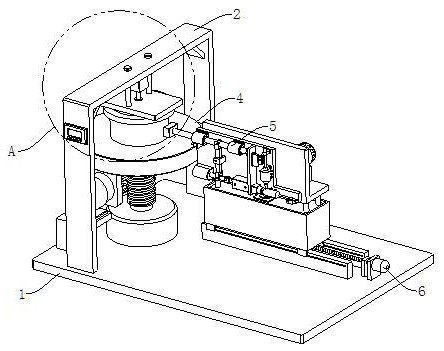

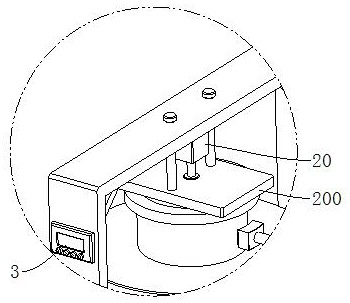

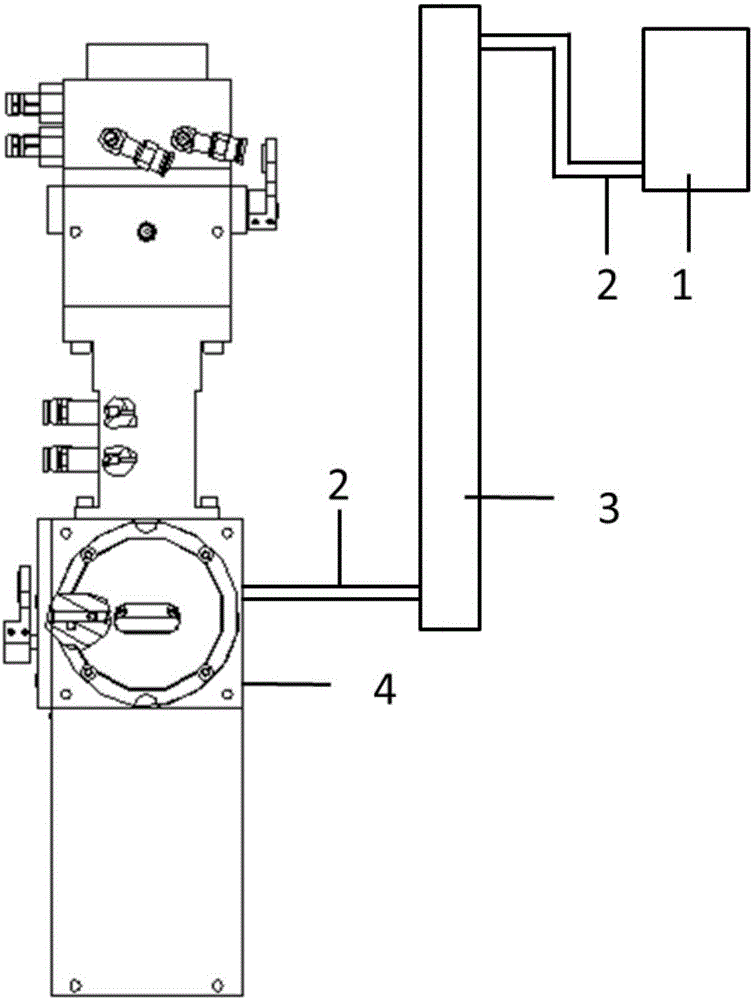

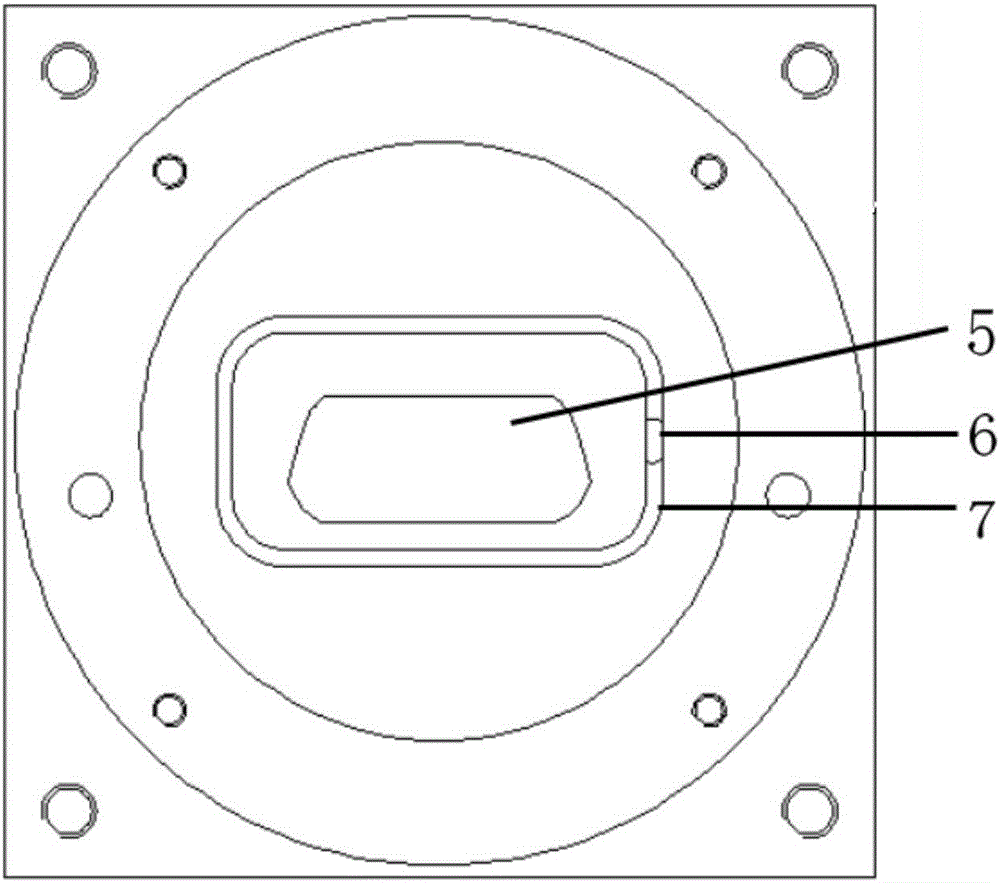

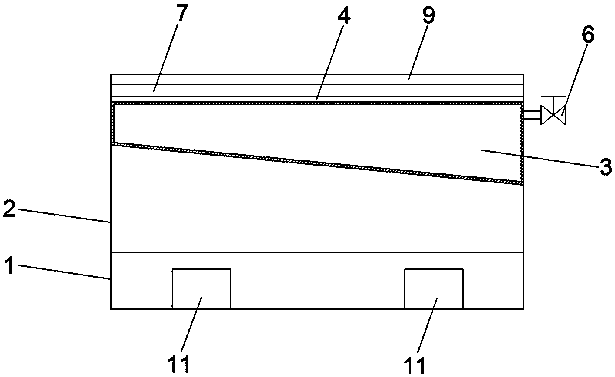

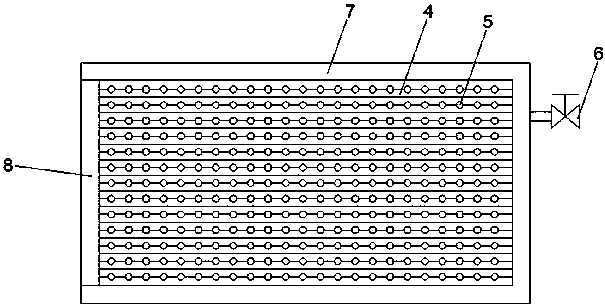

Sample shaping system for X-ray fluorescence on-line testing

The invention discloses a sample shaping system for X-ray fluorescence on-line testing. The system comprises an X-ray fluorescence on-line tester and a vacuum pump, wherein an analysis testing bin plate of the X-ray fluorescence on-line tester is provided with an analysis testing window; the analysis testing window is provided with a support film; vacuum negative-pressure bleeder holes are arranged around the analysis testing window; and the vacuum negative-pressure bleeder holes are connected with the vacuum pump through a connecting pipeline. The vacuum pump is added on the basis of the X-ray fluorescence on-line tester; the vacuum negative-pressure mode is adopted to implement the sample shaping effect, thereby ensuring the analyzed surface of the sample to be always smooth, and ensuring the X-ray fluorescence to precisely implement the on-line analysis on the powdered sample.

Owner:长沙开元仪器有限公司

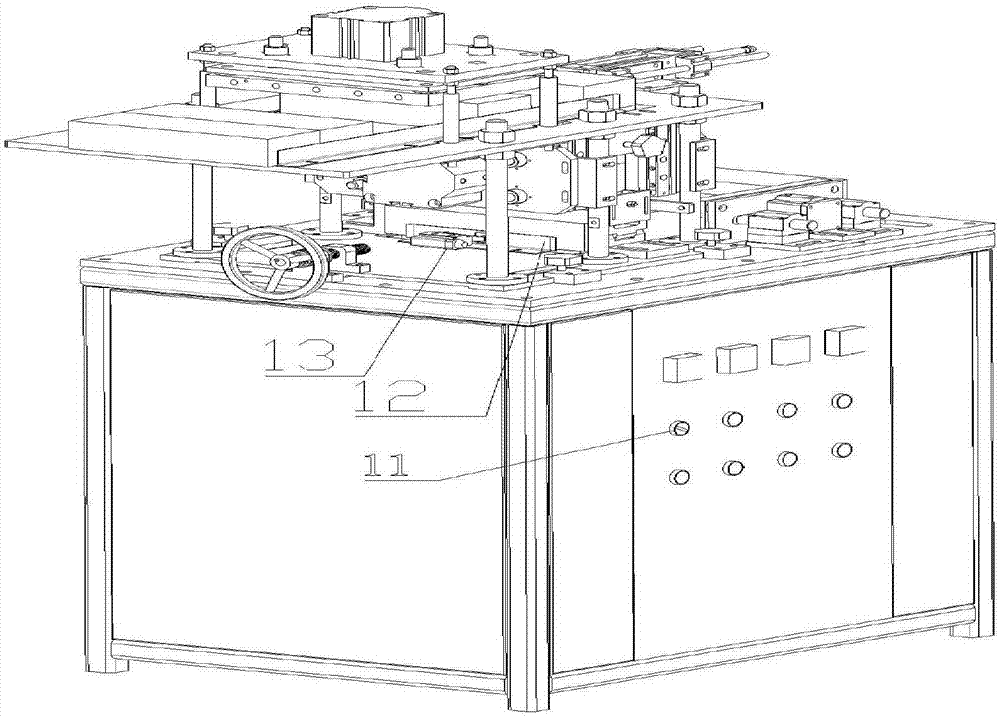

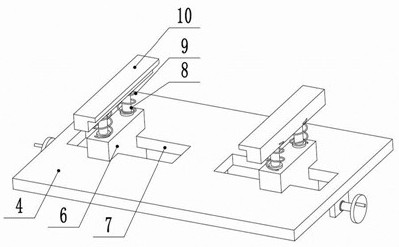

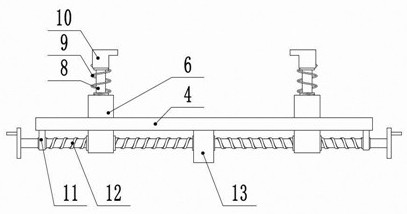

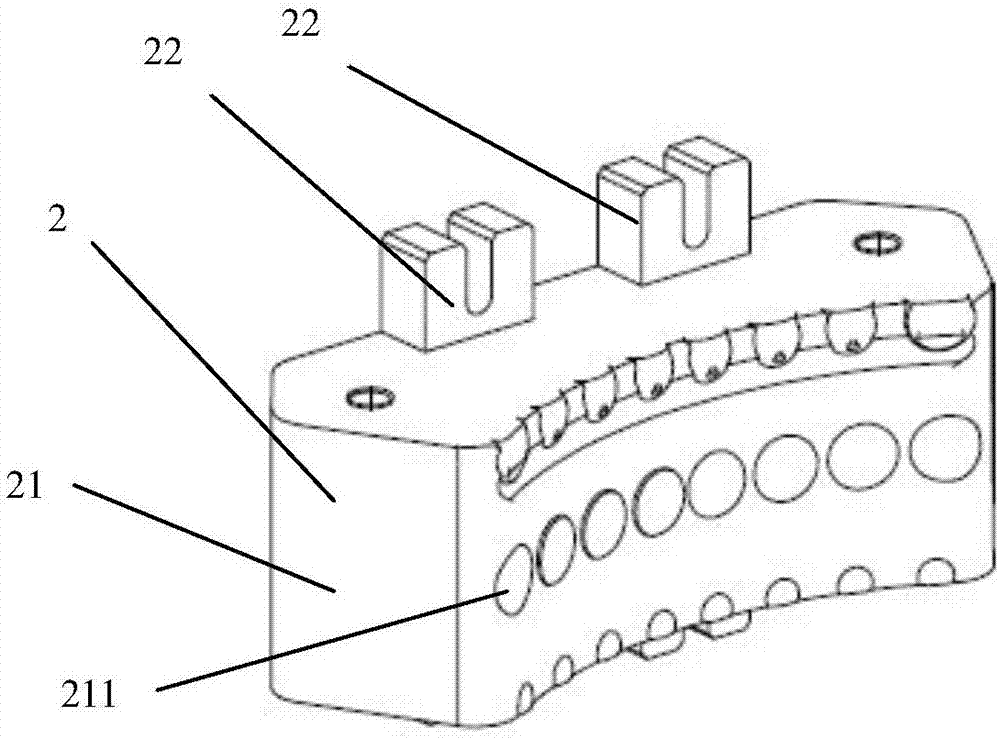

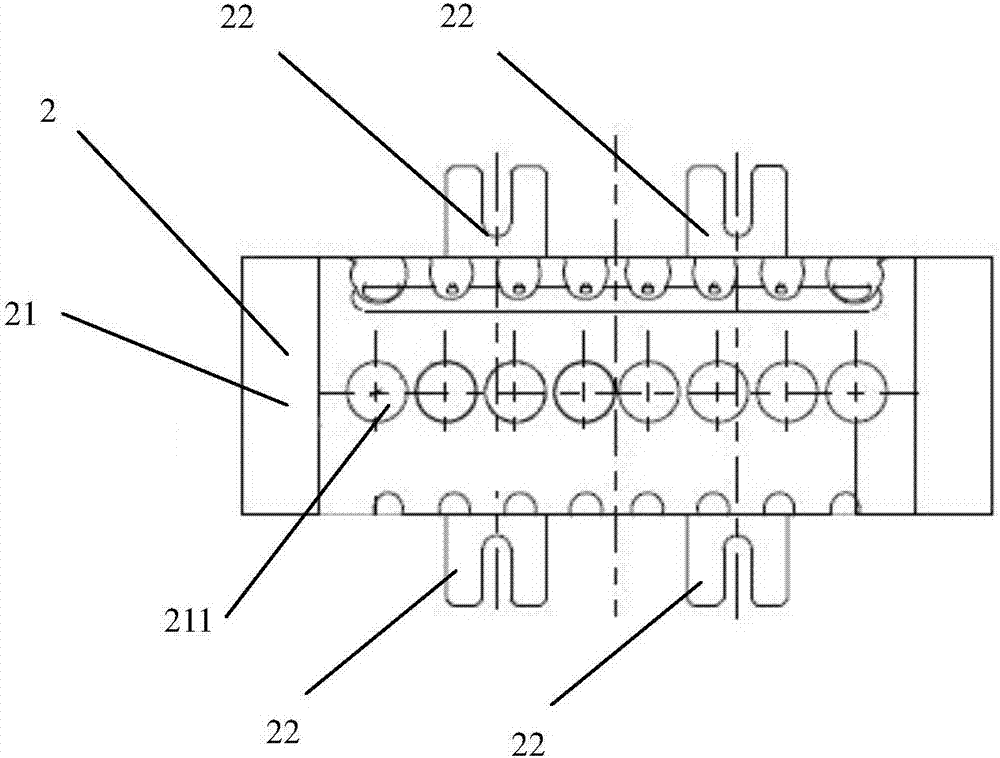

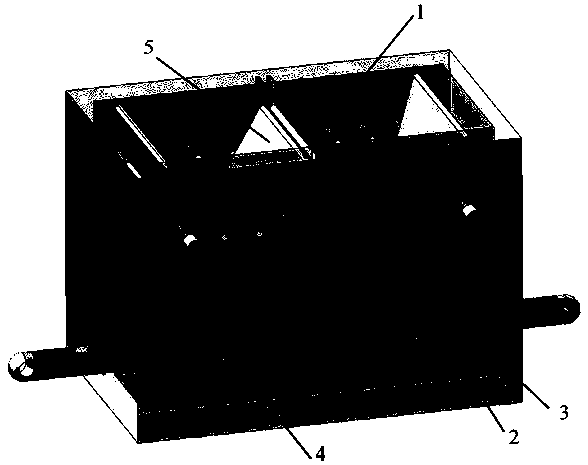

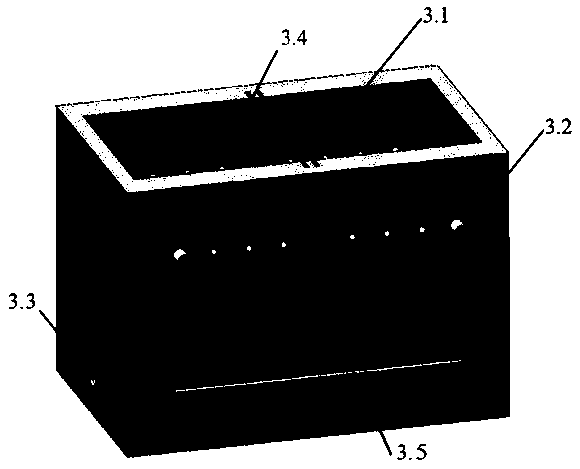

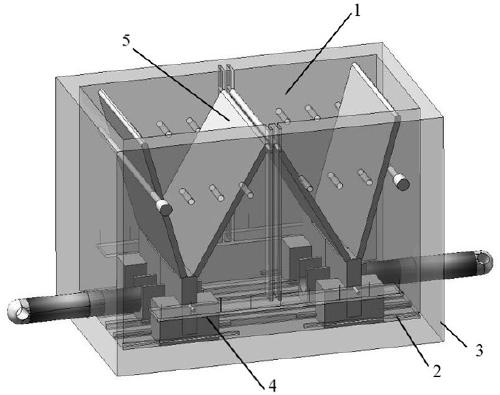

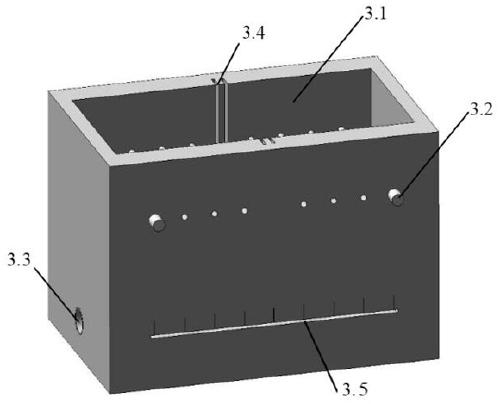

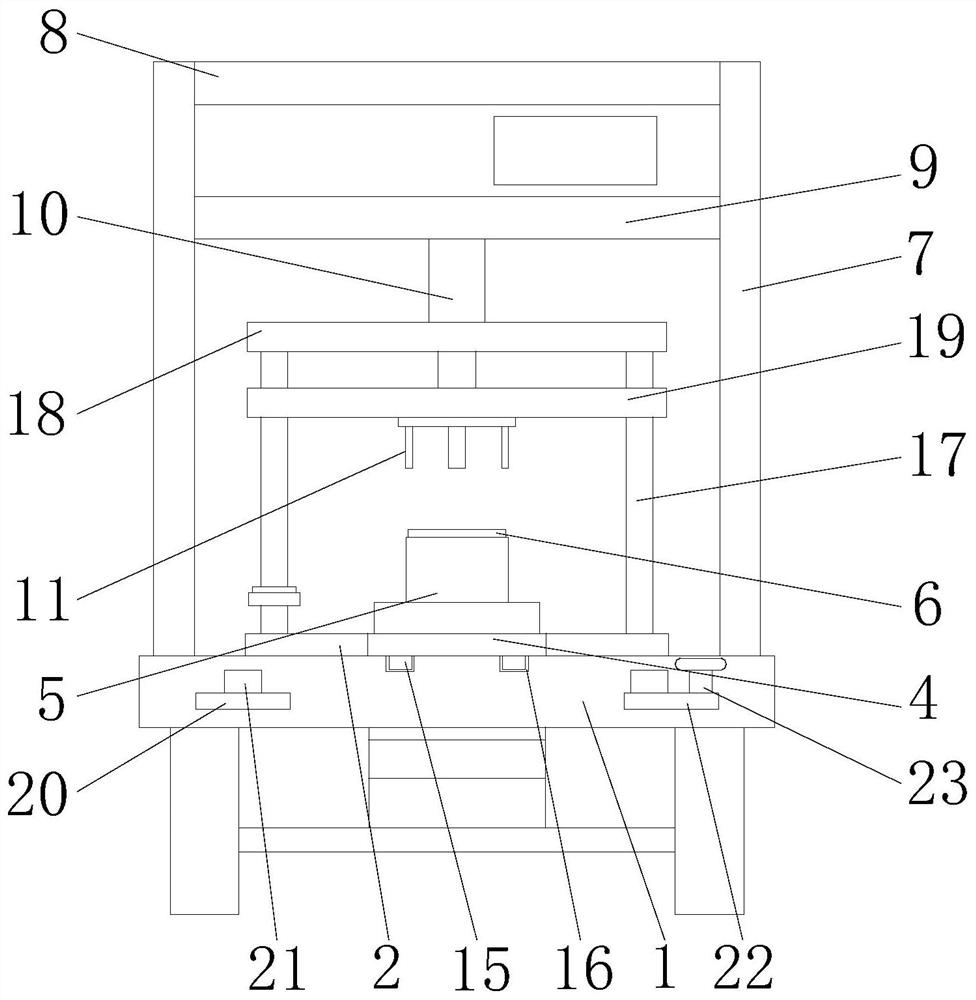

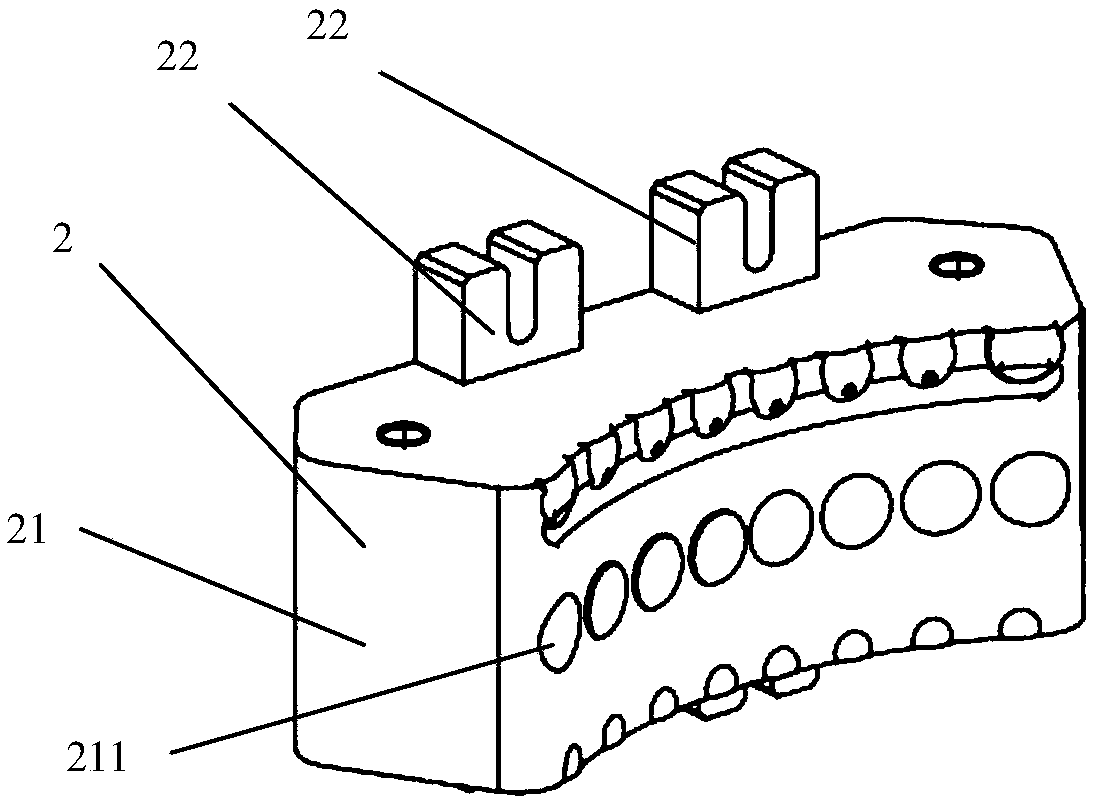

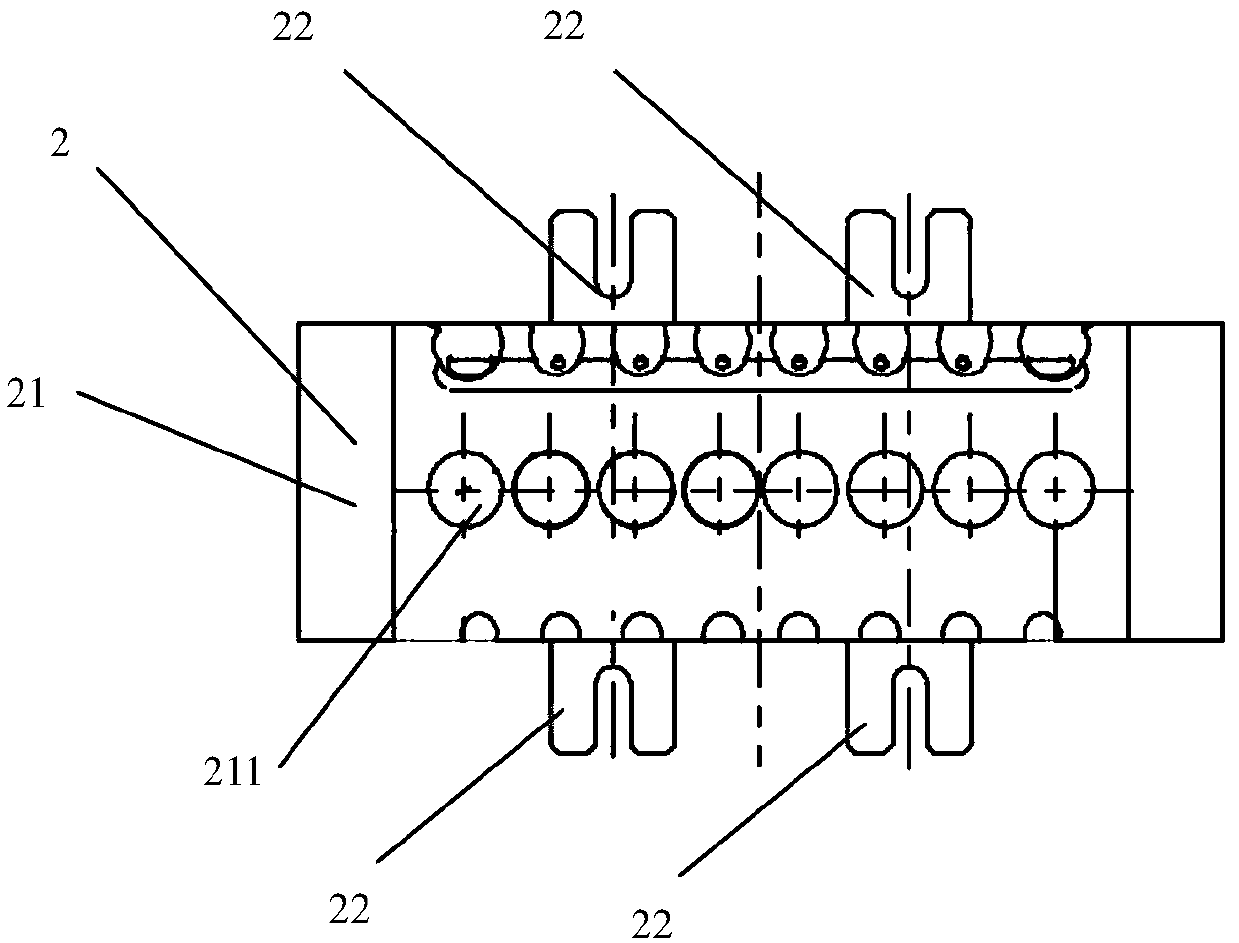

Shaping device for powder injection molding type clamp part

ActiveCN109128179AAchieve plastic effectReduce shaping errorTurbinesOther manufacturing equipments/toolsMechanical engineeringPowder injection molding

The invention discloses a shaping device for a powder injection molding type clamp part. The device comprises a rack, a screw positioning device and a baffle plate, wherein the screw positioning device is movably connected to the baffle plate; a storing chamber for storing the baffle plate and the screw positioning device is formed in the rack; a movable chute which fits the screw positioning device is formed in the inner bottom part of the rack; the rack comprises a rack body; baffle plate positioning chutes are symmetrically formed in the middle parts of the inner walls of two side edges ofthe long side of the rack body; a plurality of holes through which pin pass and scale lines are arranged at intervals on two side surfaces of the long side of the rack body; screw inserting holes areformed in two sides of the short side of the rack body; the screw positioning device comprises an inner sliding block, outer sliding blocks and a screw; and the outer sliding blocks are symmetricallyarranged at two sides of the inner sliding block. According to the device, the screw and the scale line are matched to accurately adjust the angle of the baffle plate; the angles or distances of different parts are combined, so that the part shaping effect can be realized without replacing a die under the condition that similar parts are deformed differently.

Owner:PINGXIANG HUICHENG PRECISION MACHINERY & ELECTRONICS

Thermal wind shaping and aroma increasing machine

InactiveCN109463473AGood plastic effectPrevent splashing outPre-extraction tea treatmentEngineeringThermal wind

The invention relates to a thermal wind shaping and aroma increasing machine. The thermal wind shaping and aroma increasing machine comprises a base, wherein a machine frame is arranged on the base; athermal wind cavity is arranged on the machine frame; the top of the thermal wind cavity is a W-shaped multi-bent top plate; a plurality of ventilating holes are formed in grooves of the W-shaped multi-bent top plate; and a thermal wind valve is arranged on one side of the thermal wind cavity. According to the thermal wind shaping and aroma increasing machine provided by the invention, the shaping effect is good, and tea leaves cannot be splashed out due to blowing by wind; the top of the thermal wind cavity adopts the W-shaped multi-bent top plate, so that the tea leaves can fall into the grooves of the W-shaped multi-bent top plate, and the shaping effect is better; a gauze board is additionally arranged, so that the tea leaves blown by thermal wind are blocked by a gauze, and fall downto the grooves of the W-shaped multi-bent top plate, the situation that the tea leaves are splashed out is effectively prevented, the tea leaves fall down to the grooves of the W-shaped multi-bent top plate, and the shaping effect is further achieved; and a vibrating motor is arranged in the base, so that the tea leaves are better shaped in the grooves of the W-shaped multi-bent top plate.

Owner:宜昌三峡原红茶业有限公司

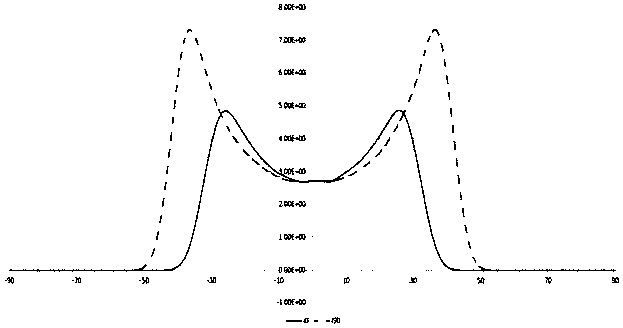

A micro-lens array element for light spot shaping

The invention discloses a micro-lens array element for light spot shaping. The method comprises the following steps: S1, selecting a plurality of proper micro-lens array lenses, S2, selecting the characteristic size of a single micro-lens unit of the micro-lens array in the step S1 to be 10-100 microns; S3, enabling the light energy utilization rate of the single micro-lens array lens element to be greater than 80%; S4, carrying out corresponding sequence arrangement according to actual requirements; S5, after the step S4 is completed, focusing the lens of the micro-lens array on a focal plane; and S6, finally, debugging the finished assembly, designing an effective surface for the micro-lens of each unit by using a bionic surface, preferably processing the micro-lens of each unit by usinga metal mold and a plastic material, and forming a repeated array in which the micro-lenses of each unit are densely arranged. According to the invention, the specially designed regular micro-lens array is adopted, and after the emergent light of the light source passes through the regularly and densely arranged micro-lens array, various special light spot shaping effects can be realized.

Owner:合肥嘉东光学股份有限公司

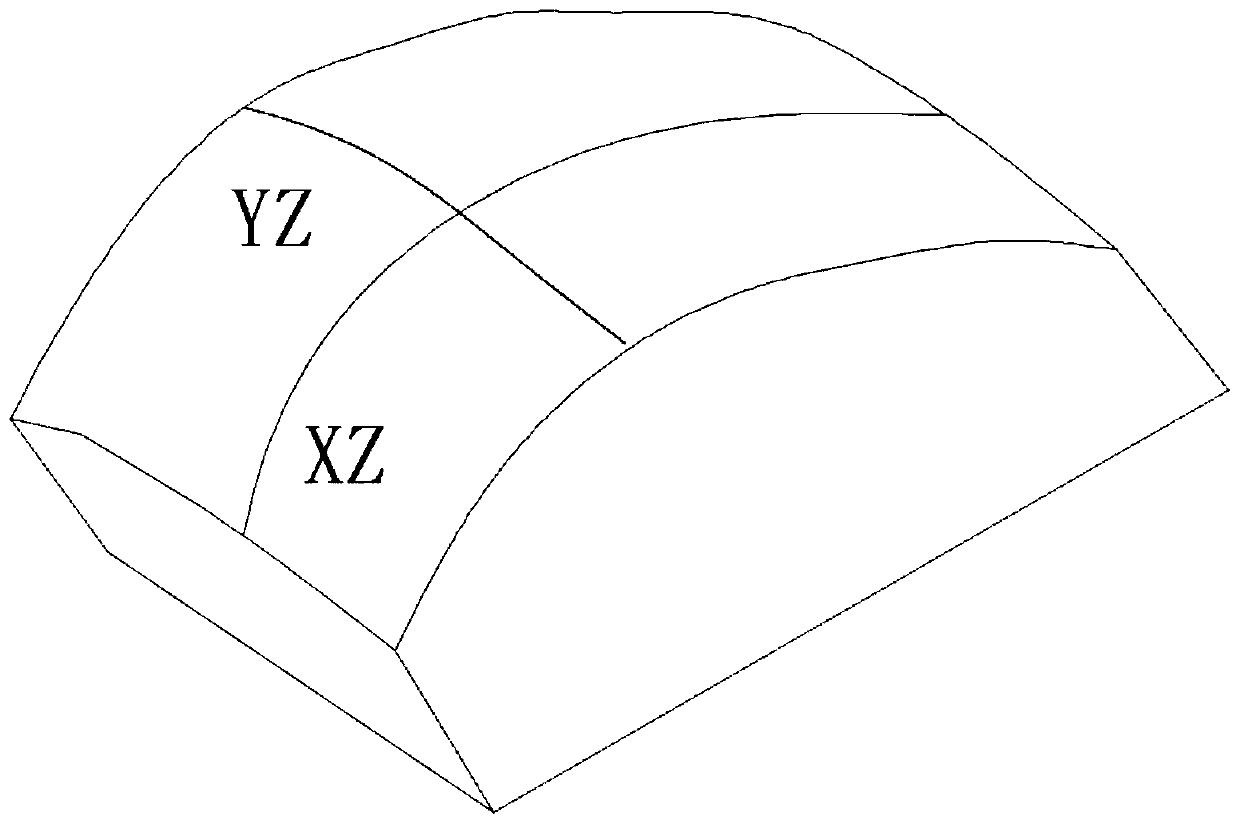

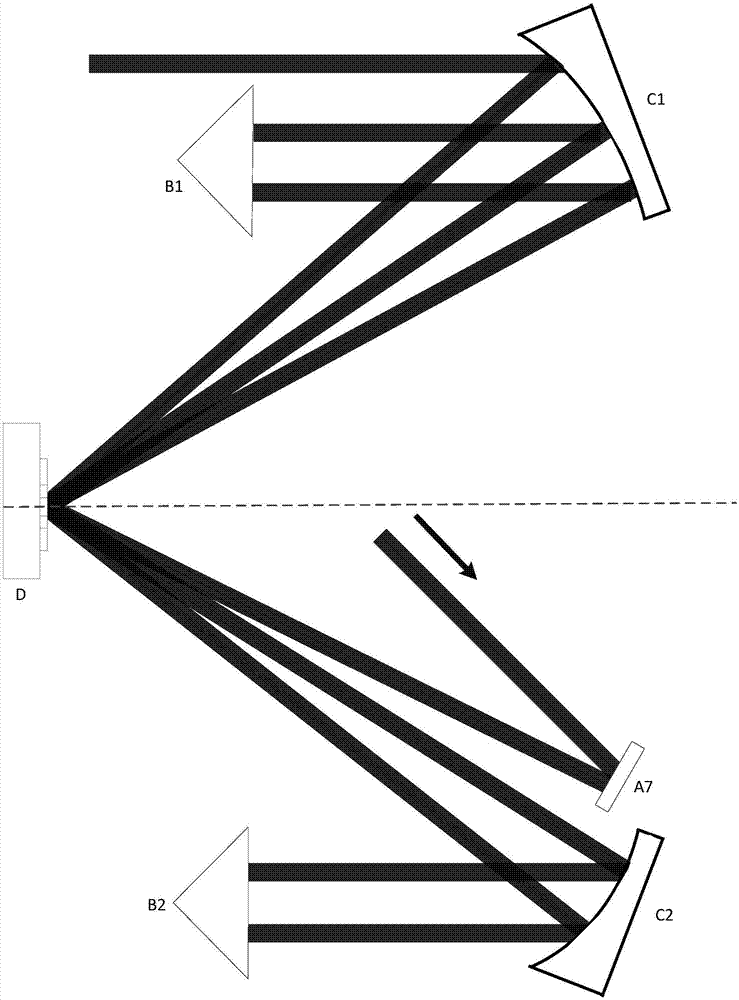

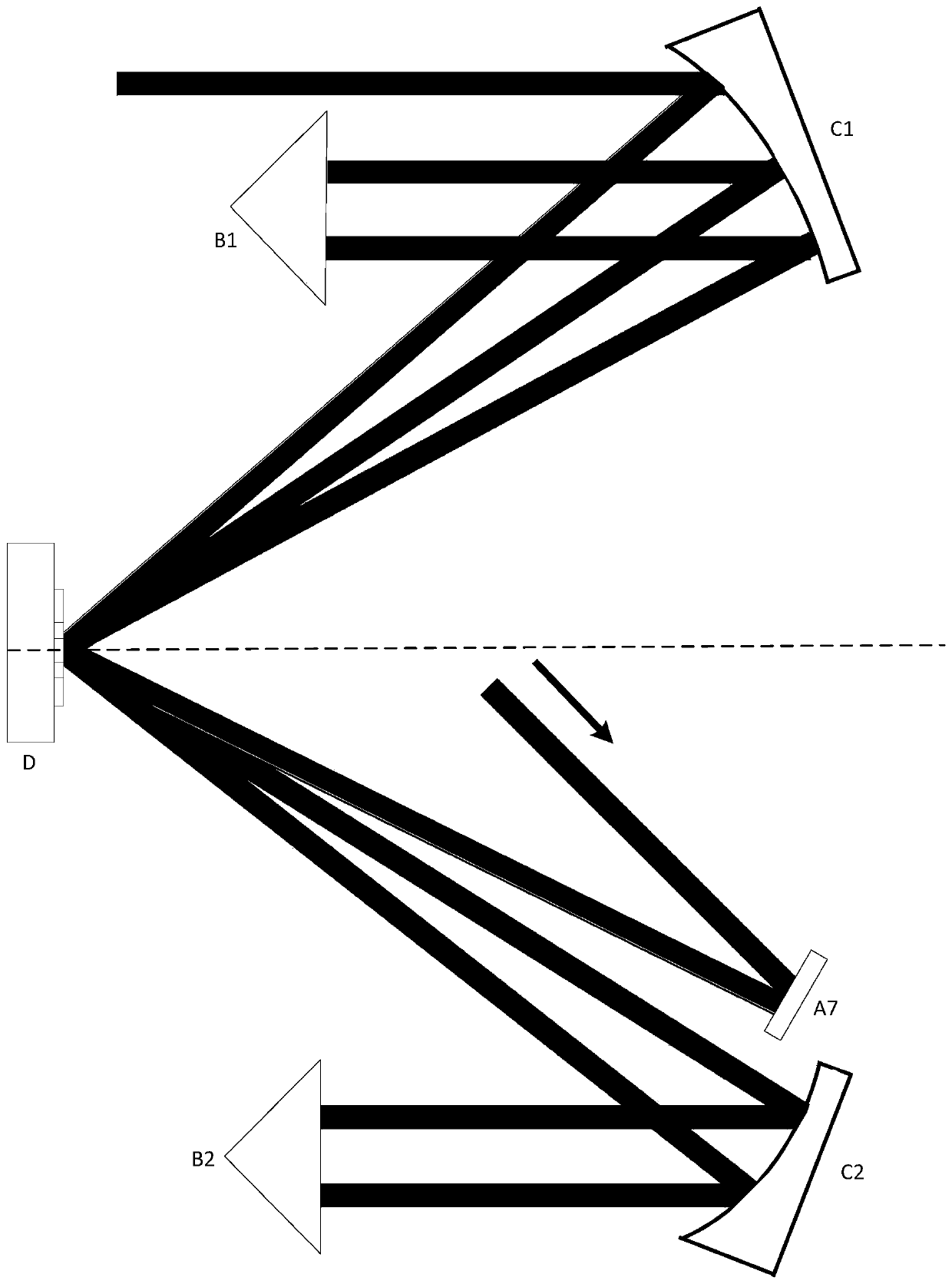

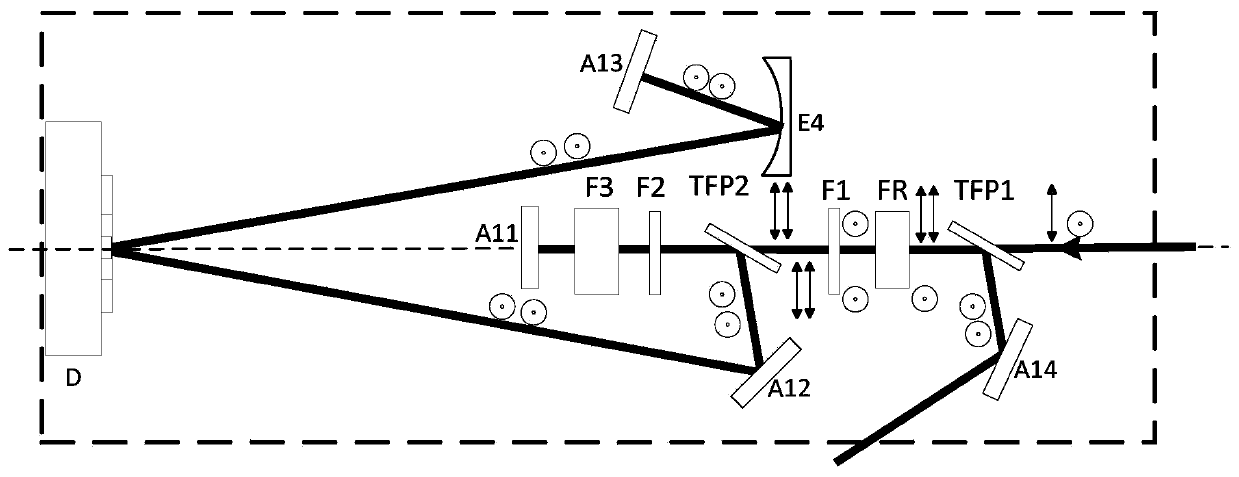

Laser amplification method and solid laser amplifier based on disc crystal

ActiveCN107039878AAvoid damageIncrease profitActive medium shape and constructionAudio power amplifierLight spot

The invention discloses a laser amplification method and a solid laser amplifier based on a disc crystal. Two amplification units share a disc crystal D, and seed light is amplified by the disc crystal D in one amplification unit, and thereafter the collimation and beam expanding of the amplified seed light is carried out, and then the seed light is transmitted to the other amplification unit, and is further amplified by the disc crystal D. The method and the device provided by the invention are advantageous in that the seed light of low energy level is amplified, and thereafter is further amplified after the collimation and beam expanding, and therefore on one hand, overhigh peak power caused by one-time direct amplification is prevented, and instruments and elements are prevented from being damaged, and on the other hand, output light beams tend to be flat, and shaping effect is achieved; light spots of different sizes in the two amplification units are transmitted to the same disc crystal D to acquire gain, and therefore the utilization rate of the gain area of the disc crystal D is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

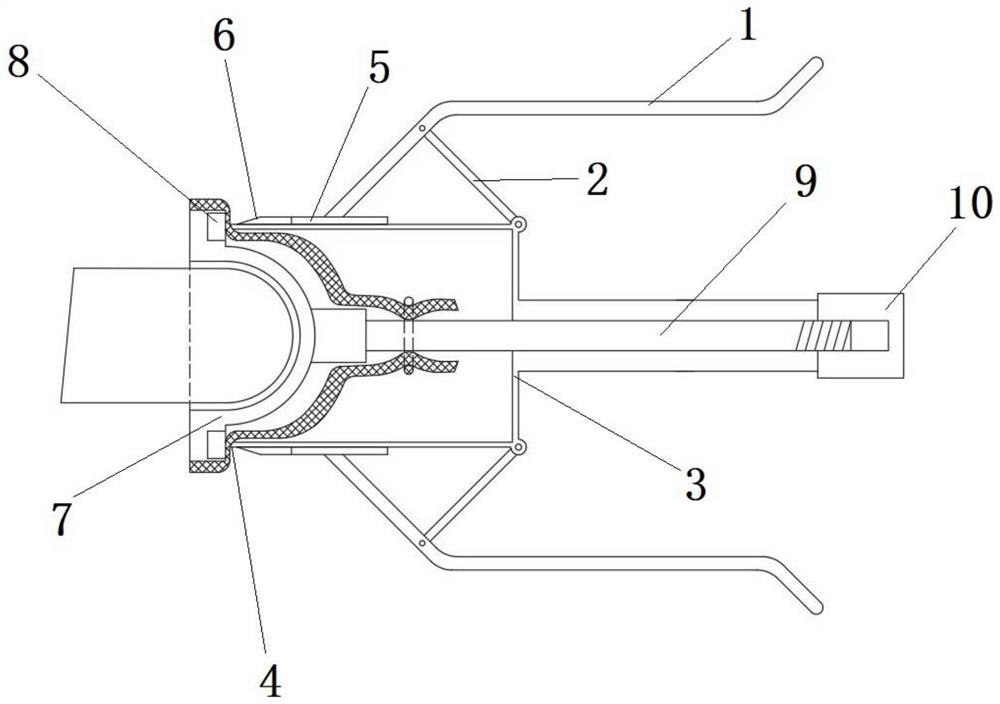

Prepuce shaping and cutting device

InactiveCN113616289ARelieve diseaseTo achieve aesthetic (plastic) effectDiagnosticsSurgeryForeskinEngineering

The invention relates to a prepuce shaping and cutting device, and belongs to the technical field of medical instruments. The prepuce shaping and cutting device comprises handles, connecting rods, a fixing sleeve, a movable sleeve, a cutting knife, a glans penis cover, a knife groove, a fixing rod and a limiting knob, wherein the fixing rod is arranged at the top of the glans penis cover, the fixing sleeve is arranged at the periphery of the fixing rod in a sleeving manner, and the other end of the fixing rod is provided with a thread connected with the limiting knob on the outer side of the fixing sleeve; the movable sleeve sliding relative to the fixing sleeve is arranged at the periphery of the fixing sleeve in a sleeving manner, the connecting rods are arranged on the fixing sleeve, and the connecting rods and the movable sleeve are connected with the handles at the same time; and the cylindrical cutting knife is arranged at the end, close to the glans penis cover, of the movable sleeve, and the annular knife groove corresponding to the cutting knife is formed in the base part of the glans penis cover. According to the prepuce shaping and cutting device, the defects in the prior art are overcome, the sutured wound can be in the shape of a blade of the prepuce shaping and cutting device through one-time pattern cutting of prepuce, thorough hemostasis of an electric knife and dislocation suturing, and the two-in-one effect of circumcision and reshaping is achieved.

Owner:上海英锐达医疗科技有限公司

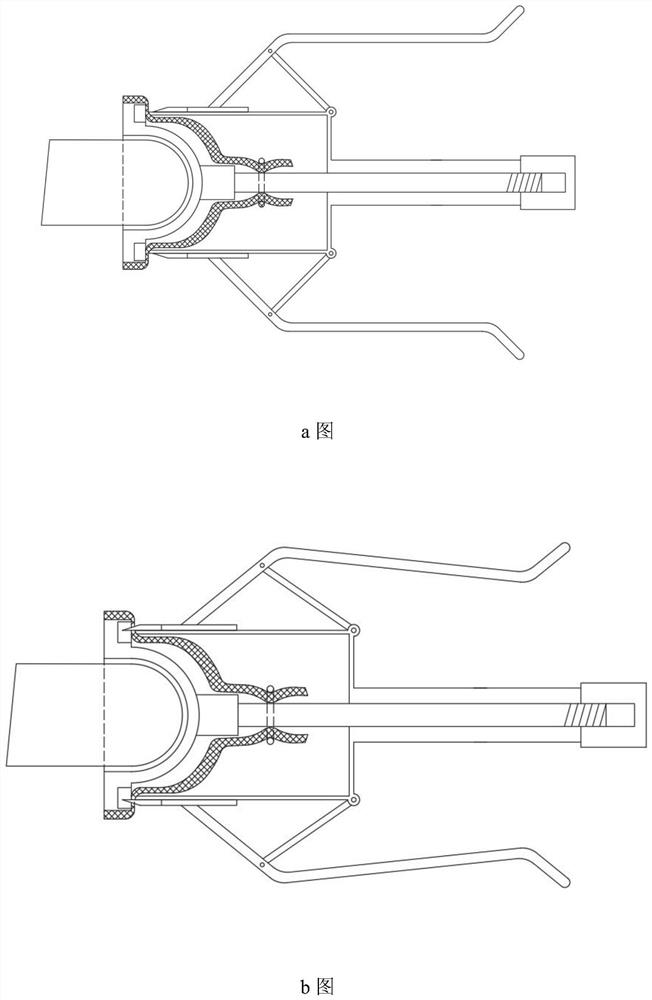

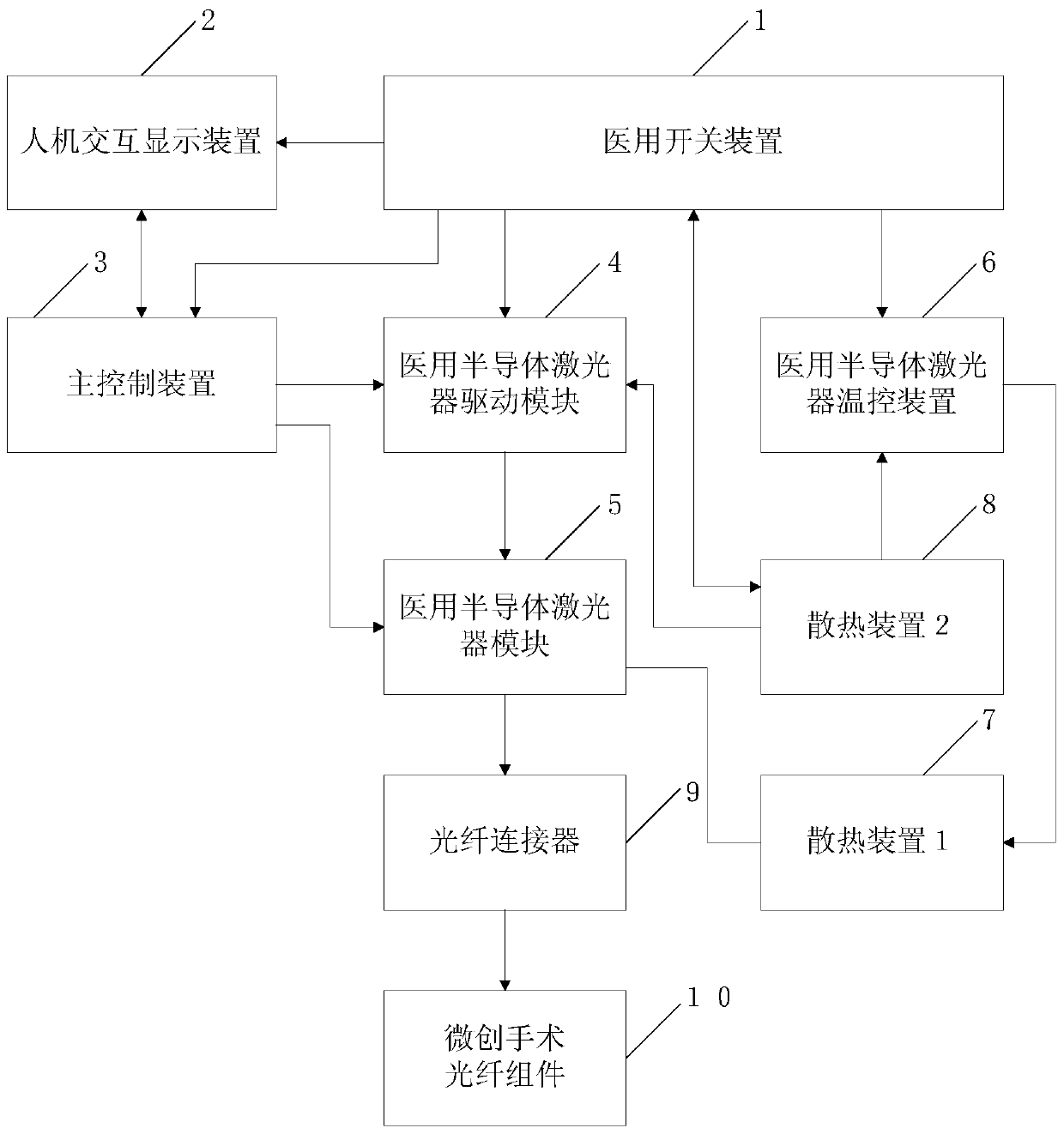

A laser therapy system for tissue ablation

ActiveCN104688337BSpherical light is easy to controlUniform light and heat temperatureSurgical instrument detailsHigh absorptionEngineering

The invention discloses a laser treatment system for tissue ablation, which includes a medical switch device, a human-computer interaction display device, a main control device, a medical semiconductor laser drive module, a medical semiconductor laser module, a medical semiconductor laser temperature control device, and a cooling device 1 , cooling device 2, optical fiber connectors and optical fiber components for minimally invasive surgery. The medical semiconductor laser module includes a first laser component and a second laser component; the wavelengths of the first laser and the second laser are different; the first laser is a visible wavelength laser used to indicate the irradiation area, and the The second laser is an eye-safe infrared wavelength laser for fat melting, which has a higher absorption rate of water and fat.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

A shaping device for powder injection molding clip parts

ActiveCN109128179BAchieve plastic effectReduce shaping errorTurbinesOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention discloses a shaping device for a powder injection molding type clamp part. The device comprises a rack, a screw positioning device and a baffle plate, wherein the screw positioning device is movably connected to the baffle plate; a storing chamber for storing the baffle plate and the screw positioning device is formed in the rack; a movable chute which fits the screw positioning device is formed in the inner bottom part of the rack; the rack comprises a rack body; baffle plate positioning chutes are symmetrically formed in the middle parts of the inner walls of two side edges ofthe long side of the rack body; a plurality of holes through which pin pass and scale lines are arranged at intervals on two side surfaces of the long side of the rack body; screw inserting holes areformed in two sides of the short side of the rack body; the screw positioning device comprises an inner sliding block, outer sliding blocks and a screw; and the outer sliding blocks are symmetricallyarranged at two sides of the inner sliding block. According to the device, the screw and the scale line are matched to accurately adjust the angle of the baffle plate; the angles or distances of different parts are combined, so that the part shaping effect can be realized without replacing a die under the condition that similar parts are deformed differently.

Owner:PINGXIANG HUICHENG PRECISION MACHINERY & ELECTRONICS

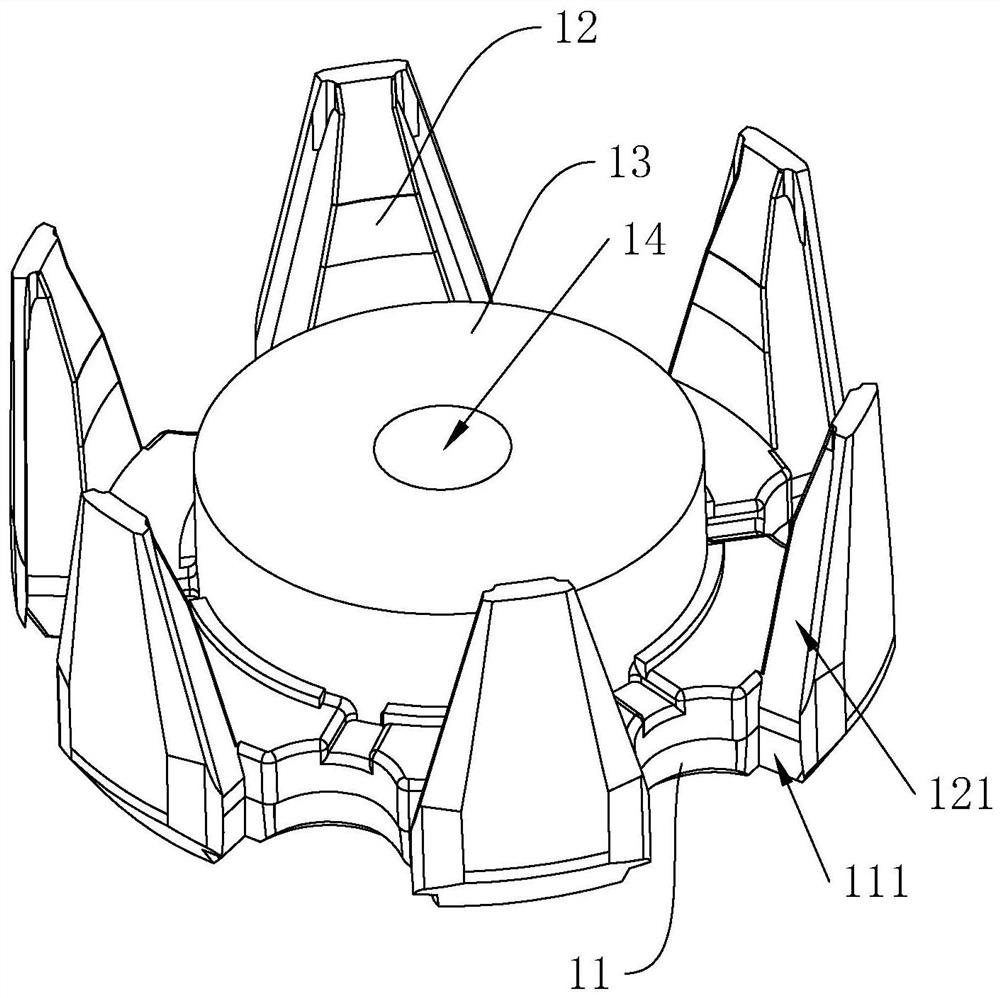

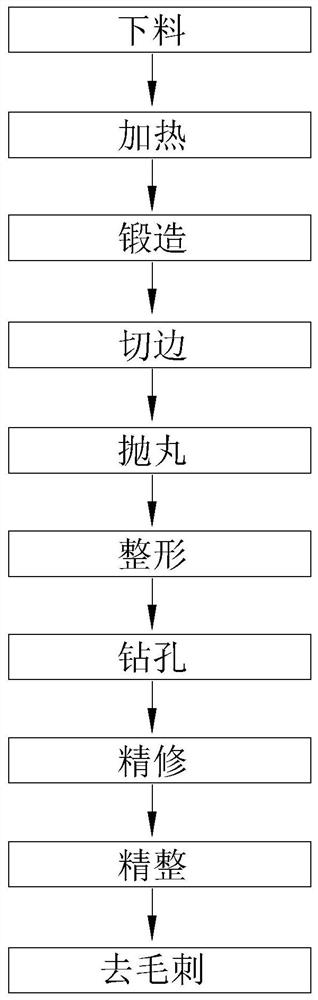

A Claw Pole for Hybrid Excitation Generator and Its Hot Forging Finishing Manufacturing Process

ActiveCN110932436BAchieve plastic effectImprove machining accuracyMagnetic circuit rotating partsManufacturing stator/rotor bodiesButt jointEngineering

The invention discloses a claw pole for a hybrid excitation generator and a hot forging finishing manufacturing process thereof and relates to the technical field of claw pole production. The problemin the prior art that operation is complicated because of assembly of magnets and claw poles is solved. . Key points of the technical scheme are as follows: the pole comprises a bottom plate, a clawruler and a magnet yoke which are integrally arranged, magnet mounting grooves are formed in the two side walls of the claw ruler, one ends of the magnet mounting grooves extend to the butt joint position of the claw ruler and the bottom plate, the other ends of the magnet mounting grooves penetrate out of the claw ruler, the claw ruler is gradually narrowed in the direction away from the base, and sliding grooves communicating with the magnet mounting grooves and used for allowing magnets to slide in are formed in the bottom plate. The claw pole can be butted firstly, and then the magnets aremounted, so that the overall assembly is facilitated.

Owner:浙江昕博汽车零部件制造有限公司

Motor rotor winding shaping machine

PendingCN111786515ATo achieve the compaction effectAchieve support effectManufacturing stator/rotor bodiesElectric machineControl theory

The invention discloses a motor rotor winding shaping machine. The shaping machine comprises a base, a first placing plate is fixedly connected to the top of the base, a groove is formed in the frontsurface of the first placing plate, a second placing plate is slidably connected to the interior of the groove, a shaper is fixedly connected to the top of the second placing plate, a pressing plate is movably connected to the top of the shaper, and supporting rods are fixedly connected to the two sides of the top of the base. According to the invention, the first placing plate and the second placing plate are arranged, the effect of placing the shaper is achieved; through the shaper, the effect of placing the rotor winding is achieved, through the pressing plate, the effect of pressing the rotor winding is achieved, through the first supporting plate and the second supporting plate, the effect of supporting the first air cylinder is achieved, through the first air cylinder, the effect ofdriving the inserting rod to move is achieved, through the inserting rod, the effect of shaping the rotor winding is achieved, and the shaping machine can effectively tidy wound wires and is convenient for people to use.

Owner:福建省昌辉机电有限公司

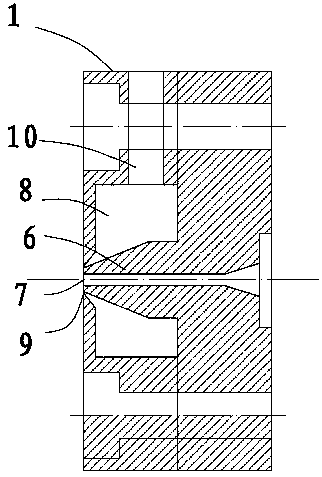

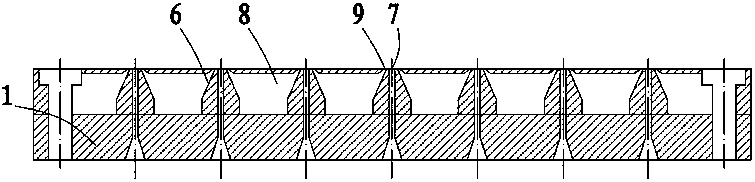

A spherical plastic powder molding device

The invention relates to a spherical plastic powder forming device. The problems that existing spherical plastic powder is large in forming difficulty and high in cost are solved. The spherical plastic powder forming device comprises an extruder, the tail end of the extruder is an extruder head, and a cooling device body is connected behind the extruder head. The spherical plastic powder forming device is characterized in that the extruder head comprises opening molds, and a round extruding outlet is formed in the center of each opening mold; air chambers are arranged around the opening mold and filled with compressed air; annular air jet ports are formed in the positions, around the extruding outlets of the opening molds, the air chambers; and the annular air jet ports jet taper air flow in the central axis directions of the extruding outlets. According to the spherical plastic powder forming device, the compressed air is adopted to assist in conducting atomization at the extruder head, so that the plastic powder are formed into spherical plastic powder which is good in sphericility degree under air flow impact; and the spherical plastic powder is cooled in a cyclone cooling device body through spiral air feeding, the rolling particle shaping effect in the cooling process is further achieved, and the product quality is improved.

Owner:ZHEJIANG ROTOUN PLASTIC TECH

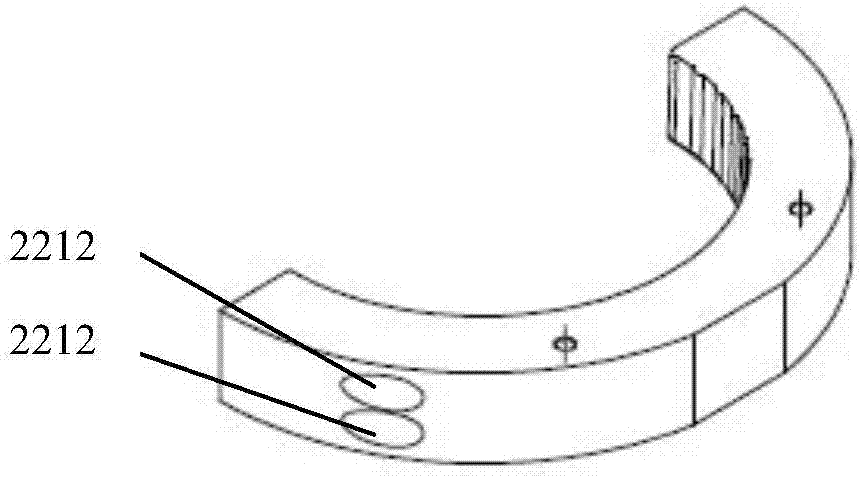

Floating block of wheel hub shaping mold

Owner:宁波路威汽车轮业有限公司

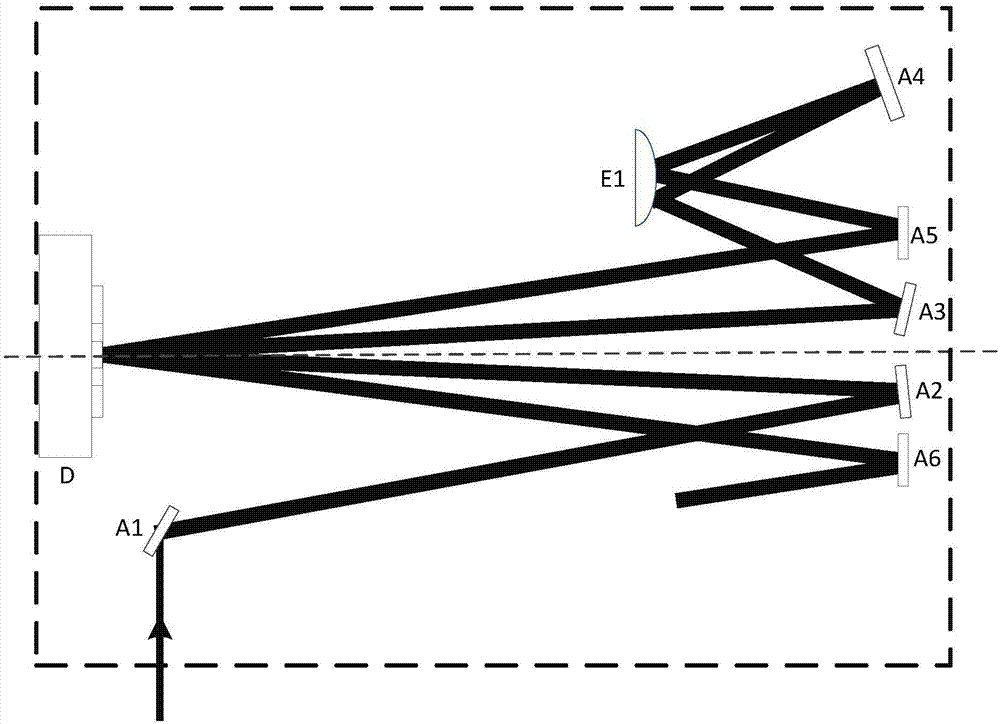

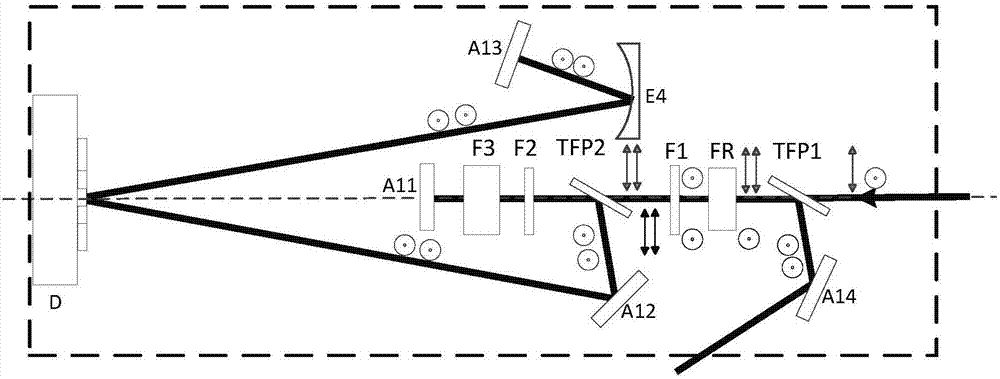

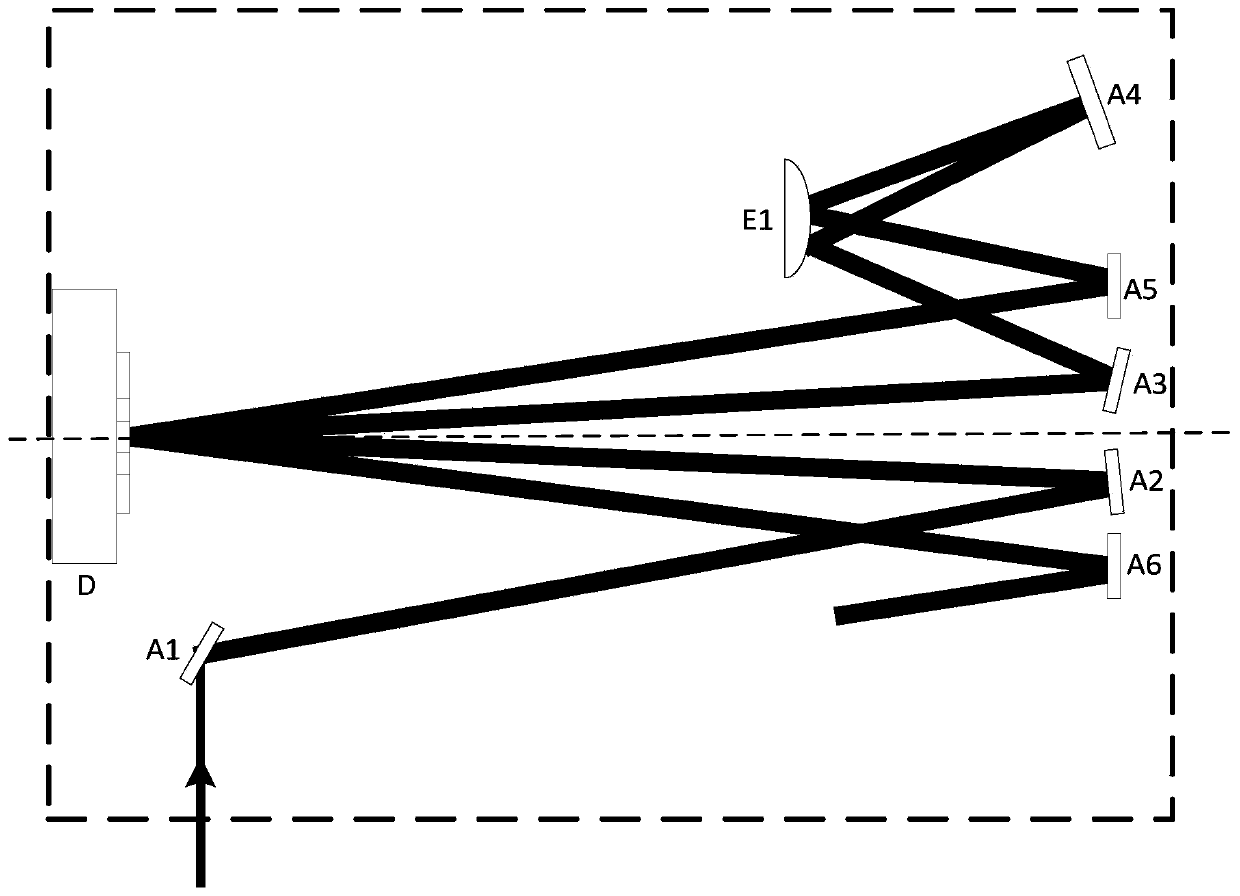

Laser amplification method based on disc crystal and solid laser amplifier

ActiveCN110112643AAvoid damageIncrease profitActive medium shape and constructionAudio power amplifierPlane mirror

The invention discloses a laser amplification method based on a disc crystal and a solid laser amplifier, which belong to the technical field of laser. The solid laser amplifier comprises optical components arranged in the optical path as follows: incidence, a plane mirror A2, a disc crystal D, a plane mirror A3,a spherical mirror E1,A4,a spherical mirror E1,a plane mirror A5,the disc crystal D and emergence. According to the method, two solid laser amplifiers share a disc crystal D; low-energy-grade seed light is amplified in one solid laser amplifier, is collimated and expanded, and then isfurther amplified in the other solid laser amplifier; on one hand, instruments and components are prevented from being damaged by high spike power caused by direct one-time amplification; on the otherhand, an output beam tends to be flat to achieve shaping; and light spots of different sizes are transmitted to the same disc crystal D to acquire gain, which greatly improves the utilization of theD-gain region of the disc crystal D.

Owner:HUAZHONG UNIV OF SCI & TECH

Floating block of wheel hub shaping mold

ActiveCN107030204BAchieve plastic effectShaping toolsMetal-working feeding devicesEngineeringSupport point

Owner:宁波路威汽车轮业有限公司

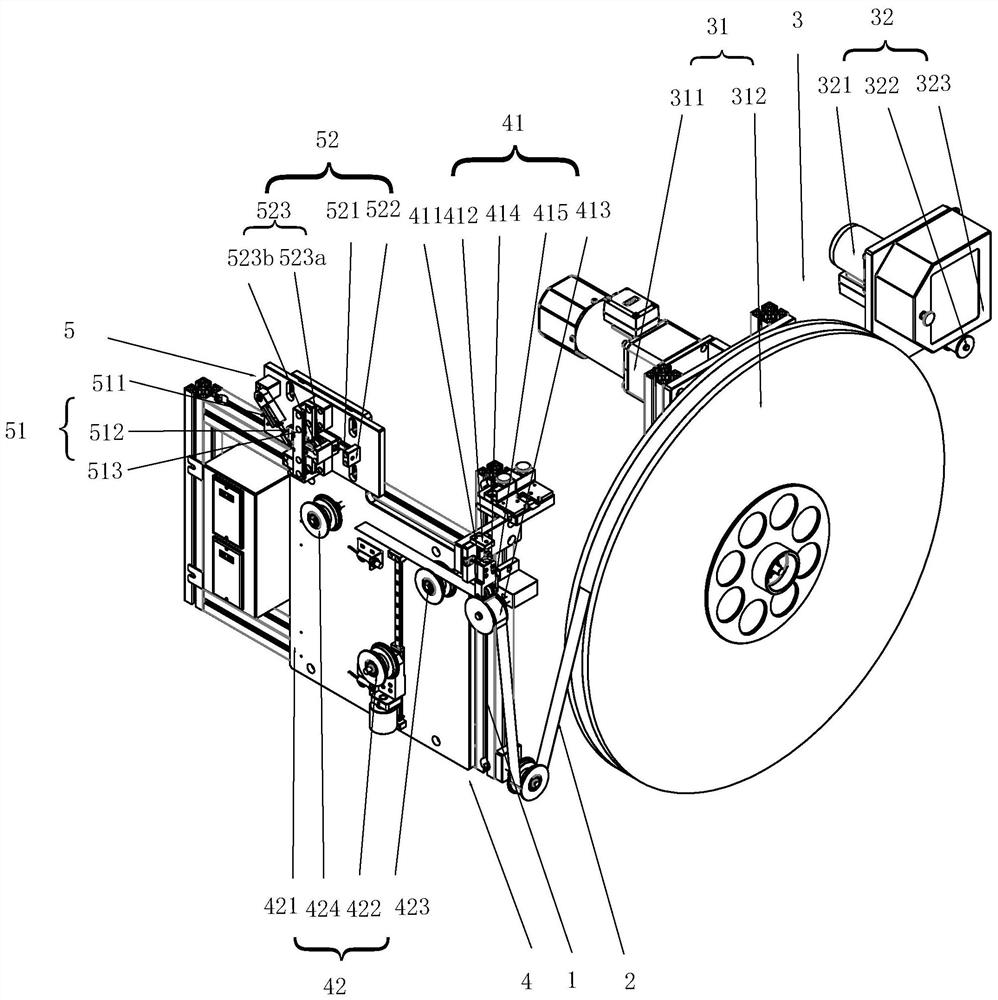

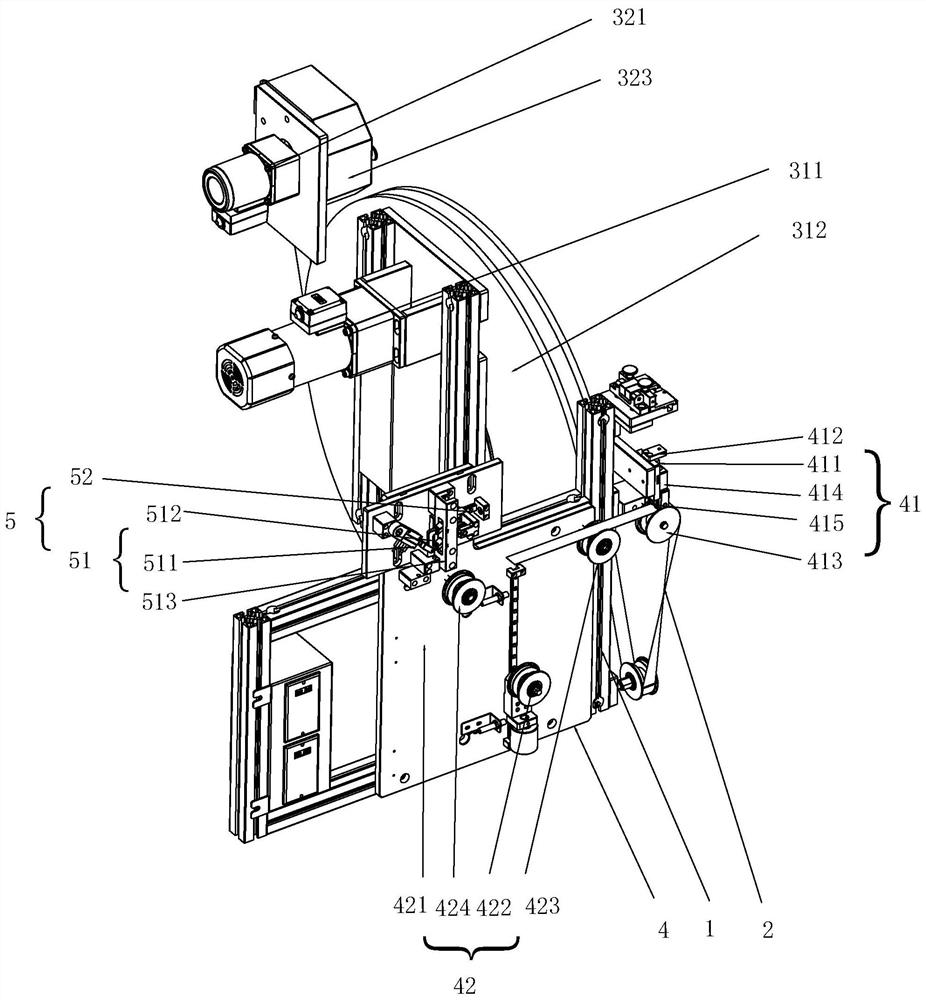

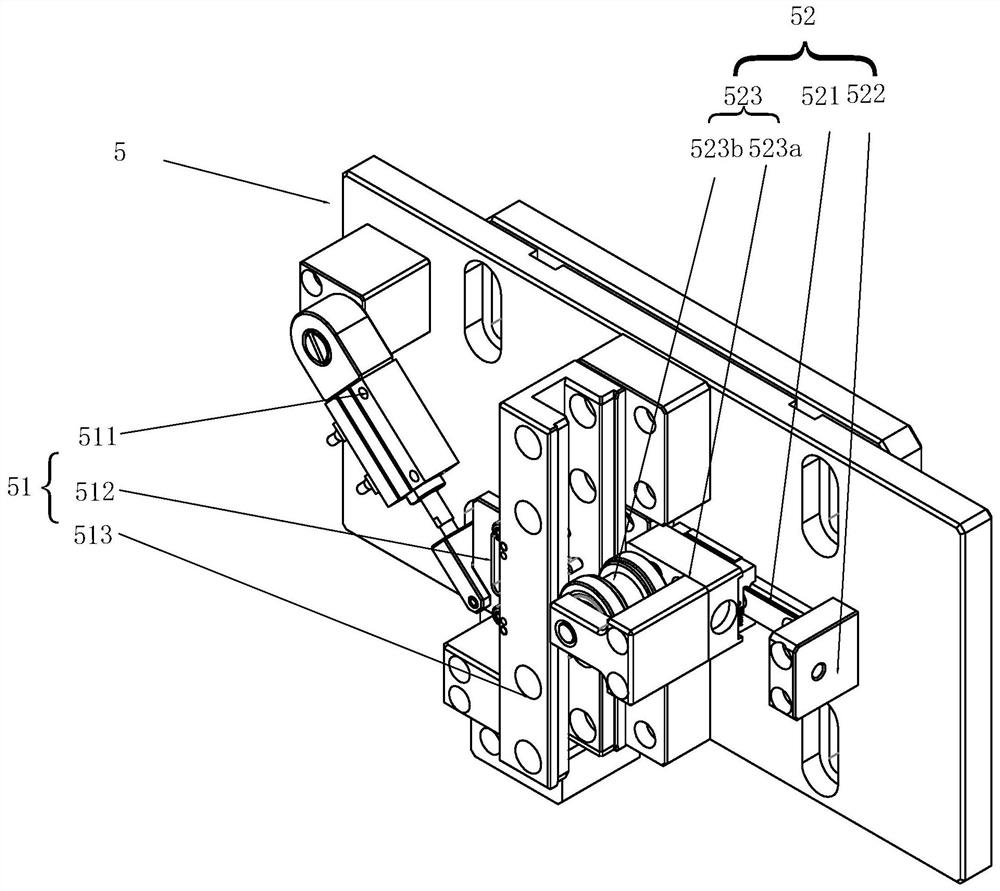

a feeding mechanism

ActiveCN109573681BEasy to deliver pressureFacilitate strippingWebs handlingEngineeringMechanical engineering

The invention discloses a feeding mechanism, which includes a rack, a discharging group, an adjusting group and a shaping group for adjusting the position of a copper shell on a material belt. The material belt sent out by the discharging group is connected with the shaping group through the adjusting group, the shaping group is provided with a toggle head and a positioning component, and when thematerial belt passes between the toggle head and the positioning component, the toggle head can be inserted into the copper shell in a reciprocating mode and matched with the positioning component tolever and regulate the angle of the copper shell on the material belt; and the toggle head on the shaping group is used for being matched with the positioning component, the copper shell passing through the material belt between the toggle head and the positioning component can be subjected to position adjustment through mutual cooperation of the toggle head and the positioning component, the toggle head is used for being matched with the positioning component to lever the angle of the copper shell, the joint between the copper shell and the material belt is exposed, a copper shell body doesnot resist the joint, the shaping effect is achieved, and the copper shell is conveniently stripped through stripping equipment in the later stage. According to the feeding mechanism, the position ofthe copper shell can be effectively adjusted, the copper shell is conveniently stripped from the material belt in the later stage, the structure is simple, and operation is convenient.

Owner:珠海市欧科锐智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com