A Claw Pole for Hybrid Excitation Generator and Its Hot Forging Finishing Manufacturing Process

A hybrid excitation and manufacturing technology, applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., can solve the problem of high requirements for workers to operate, and achieve the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

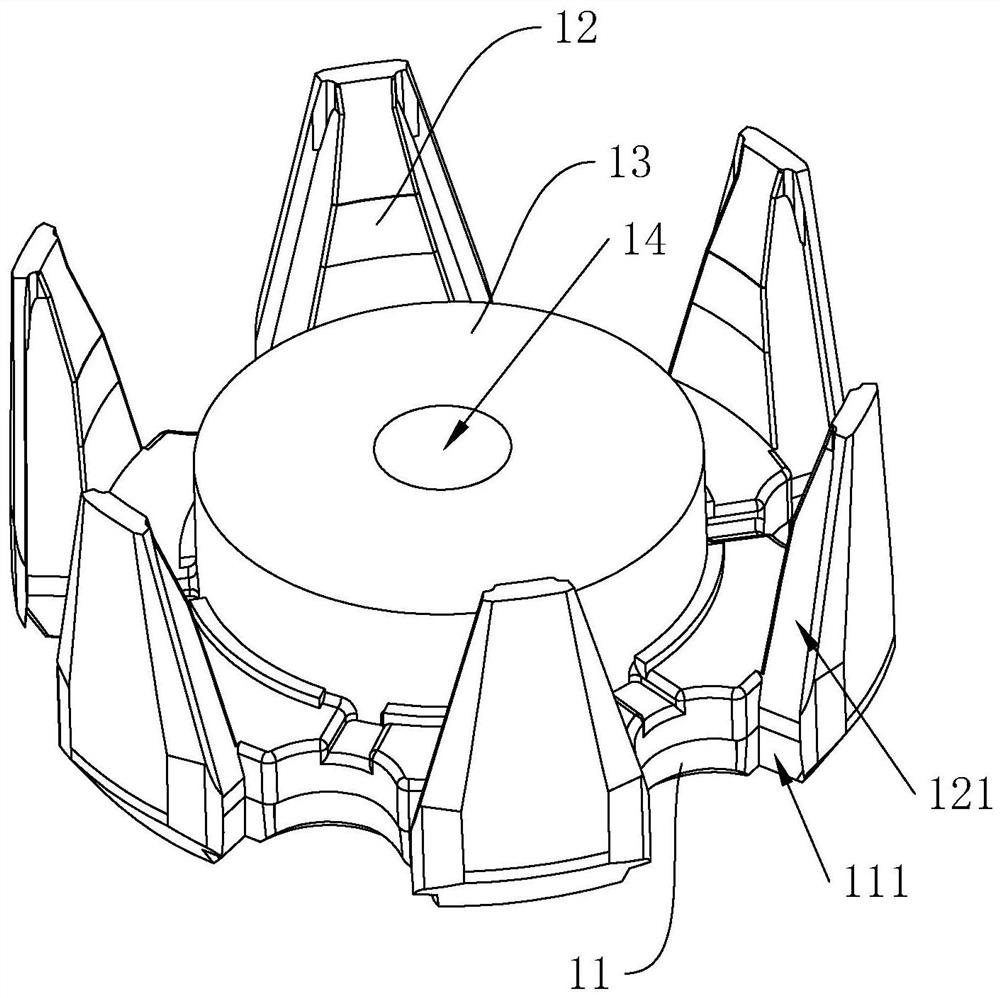

[0051] A claw pole for hybrid excitation generator, refer to figure 1 , comprising a bottom plate 11, a claw ruler 12 and a yoke 13 which are integrally arranged, and a magnet installation groove 121 is provided on both side walls of the claw ruler 12, and one end of the magnet installation groove 121 extends to the joint between the claw ruler 12 and the bottom plate 11, and the other end Through the claw ruler 12, the claw ruler 12 gradually narrows away from the base, and the bottom plate 11 is provided with a sliding groove 111 communicating with the magnet installation groove 121 for the magnet to slide in.

[0052] When in use, after the claw pole of the present application is docked with the existing claw pole, the magnet is slid in from the sliding groove 111 of the claw pole of the present application, and the magnet is completed after the base of the other claw pole is offset. Mounting, followed by positioning of the magnets via a wax seal.

Embodiment 2

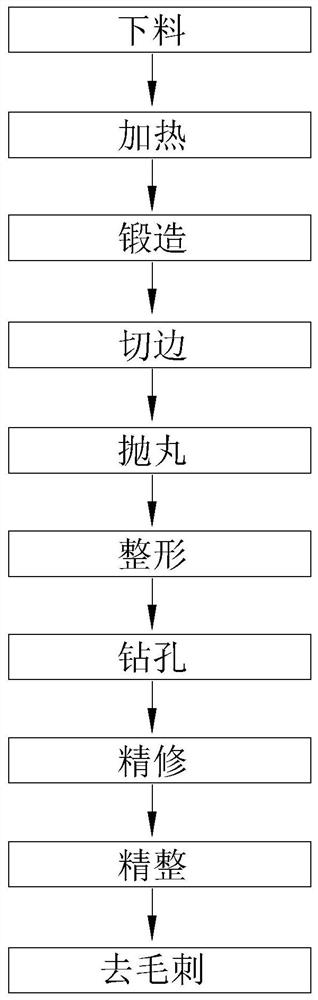

[0054] A claw pole hot forging and finishing manufacturing process for hybrid excitation generators, used to manufacture the claw poles described in Embodiment 1, refer to figure 2 , including the following specific steps:

[0055] S1, blanking, cutting the cylindrical long embryo into several sections of originals to be processed through the cutting machine, wherein the ratio of height to diameter of the originals after cutting is less than 2.

[0056] S2. Heating. The original part is heated through an intermediate frequency furnace to facilitate subsequent forging.

[0057] S3, forging, the heated original is forged by a press and processed into a finished product.

[0058] S3 specifically includes: S3.1, upsetting, extruding the heated original through the punching machine to reduce the height and increase the cross section, and remove the oxide skin on the surface at the same time; S3.2, rough forging, through 630T friction The press performs preliminary forging on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com