a feeding mechanism

A technology of feeding mechanism and material belt, which is applied in thin material handling, transportation and packaging, and winding strips, etc., can solve the problems of poor quality, low work efficiency, easy flattening and crushing of copper shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

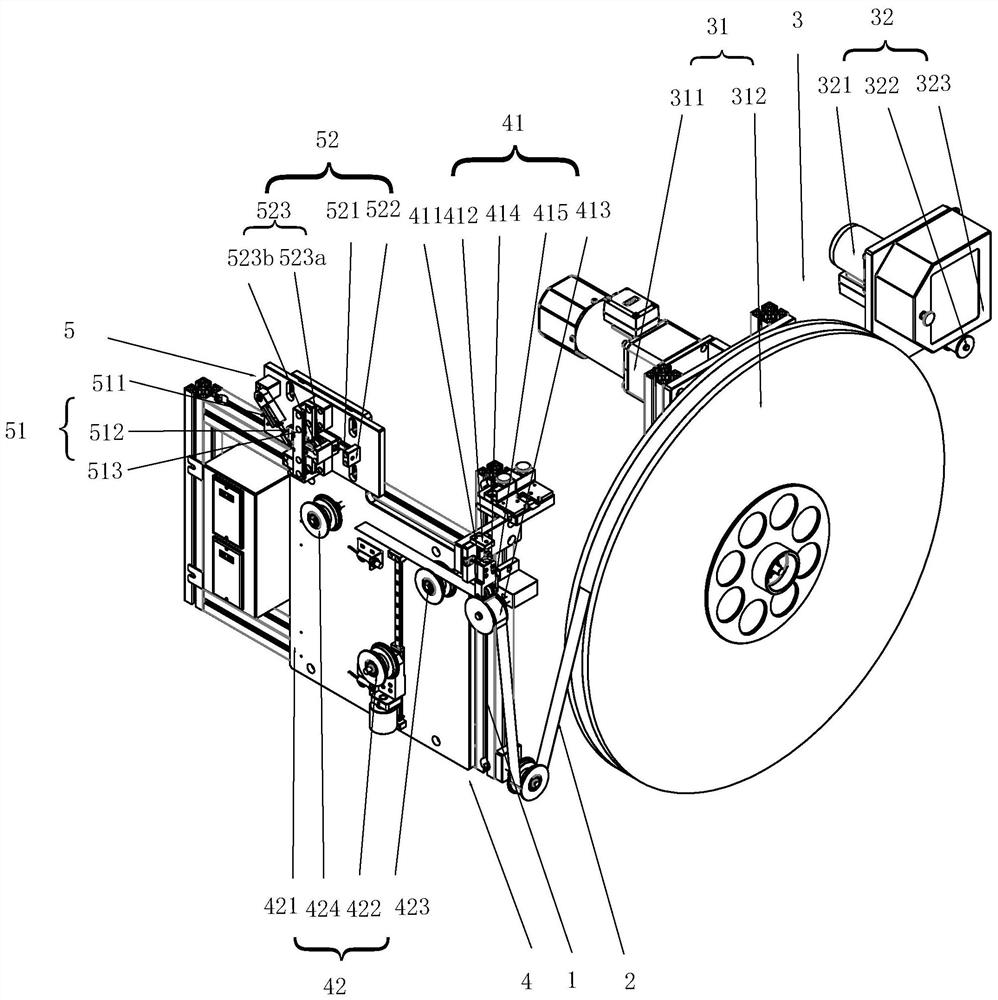

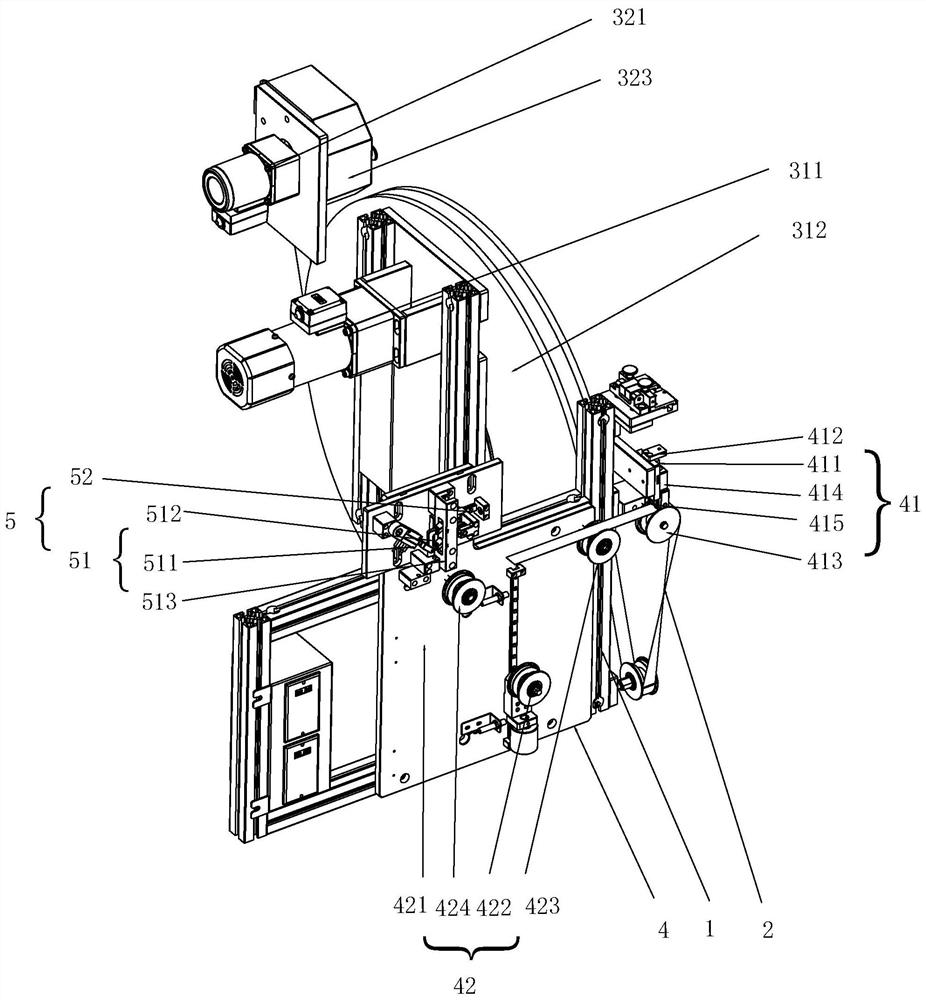

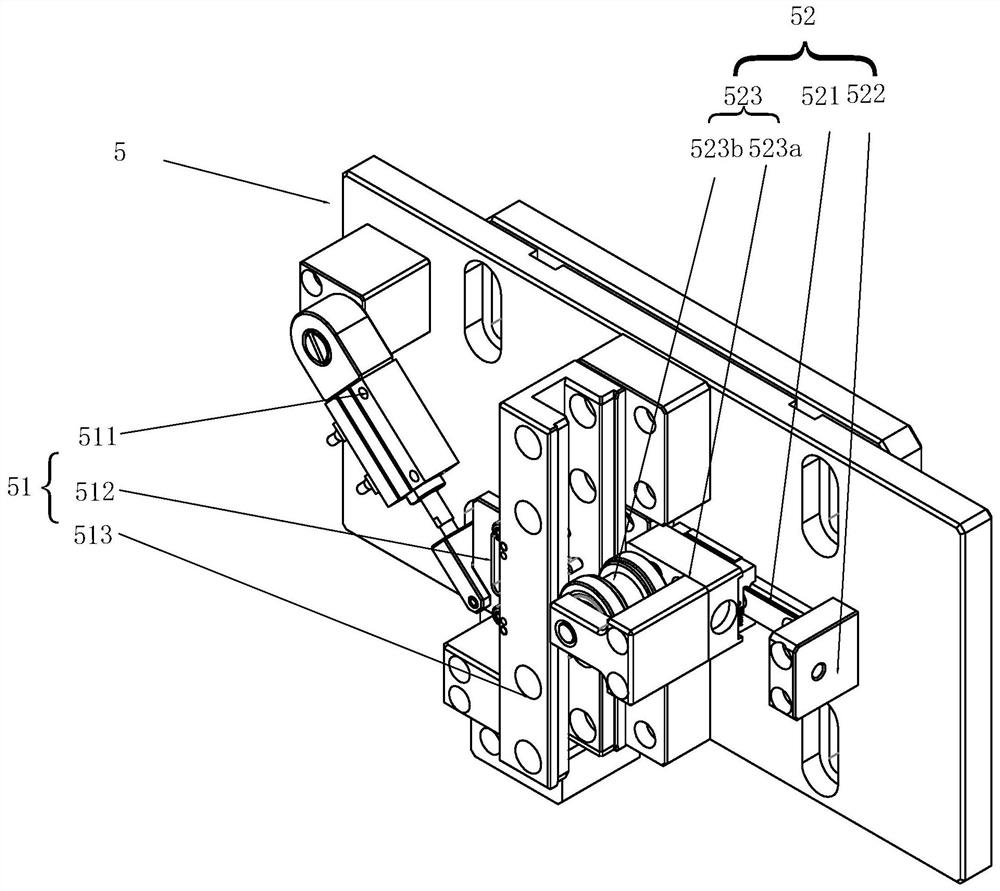

[0026] see Figure 1 to Figure 7 , a kind of feeding mechanism of the present invention, comprises frame 1, and frame 1 is provided with the discharge group 3 that is used for feeding material belt 2, the adjustment group 4 that is used to adjust the tightness of material belt 2 and is used for adjusting material belt 2 The shaping group 5 at the position of the upper copper shell, the material belt 2 sent by the discharging group 3 passes through the adjusting group 4 and is connected with the shaping group 5, and the shaping group 5 is provided with a toggle head 51 and a positioning member 52, as a material belt 2. When the toggle head 51 travels between the positioning members 52, the toggle head 51 can be reciprocally inserted into the copper shell and cooperate with the positioning member 52 to pry and adjust the angle of the copper shell on the strip 2. which see Figure 7 It can be seen that in this application, the buckle of the copper shell is adhered to the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com