Thermal wind shaping and aroma increasing machine

A technology of hot-air shaping and aroma-raising machine, which is applied in the direction of tea processing before extraction, can solve the problems of low shaping efficiency, inconsistent shaping, splashing out, etc., and achieves the effect of good shaping effect and good shaping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

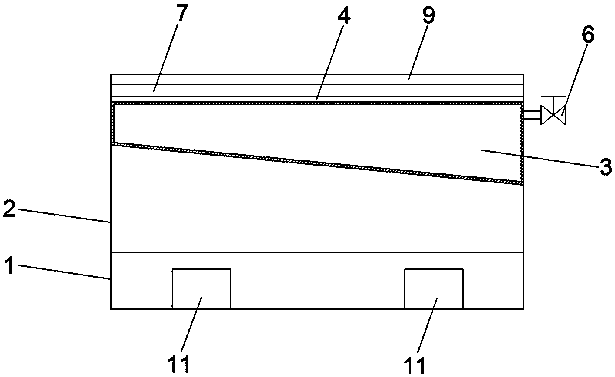

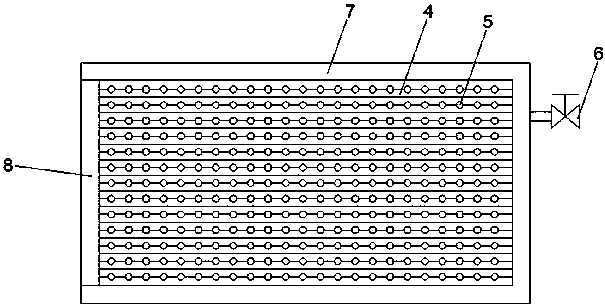

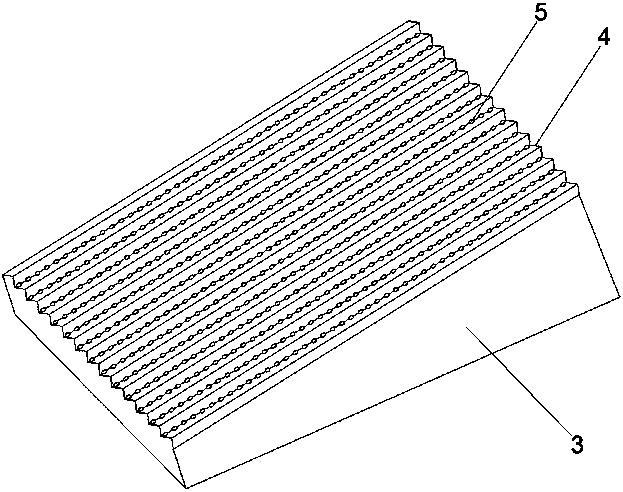

[0020] Such as Figure 1-4 As shown, a hot air shaping and aroma enhancing machine comprises a base 1, a frame 2 is arranged on the base 1, a hot air chamber 3 is arranged on the frame 2, and the top of the hot air chamber 3 is a W-shaped multi-fold top plate 4 A plurality of ventilation holes 5 are provided in the groove of the W-shaped multi-return top plate 4 , and a hot air valve 6 is provided on one side of the hot air chamber 3 .

[0021] Preferably, the outer edge of the W-shaped multi-return top plate 4 is provided with a retaining edge 7 . Surrounding edge 7 makes tealeaves can not be blown off from all around by hot wind.

[0022] Preferably, one side of the enclosure edge 3 is a detachable enclosure 8 . The detachable enclosure 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com