A micro-lens array element for light spot shaping

A micro-lens array and micro-lens technology, applied in the field of optical lenses, can solve the problems of low light transmission efficiency and difficult spot shape, and achieve the effect of high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

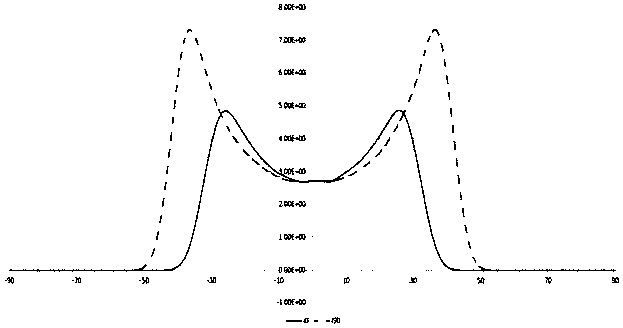

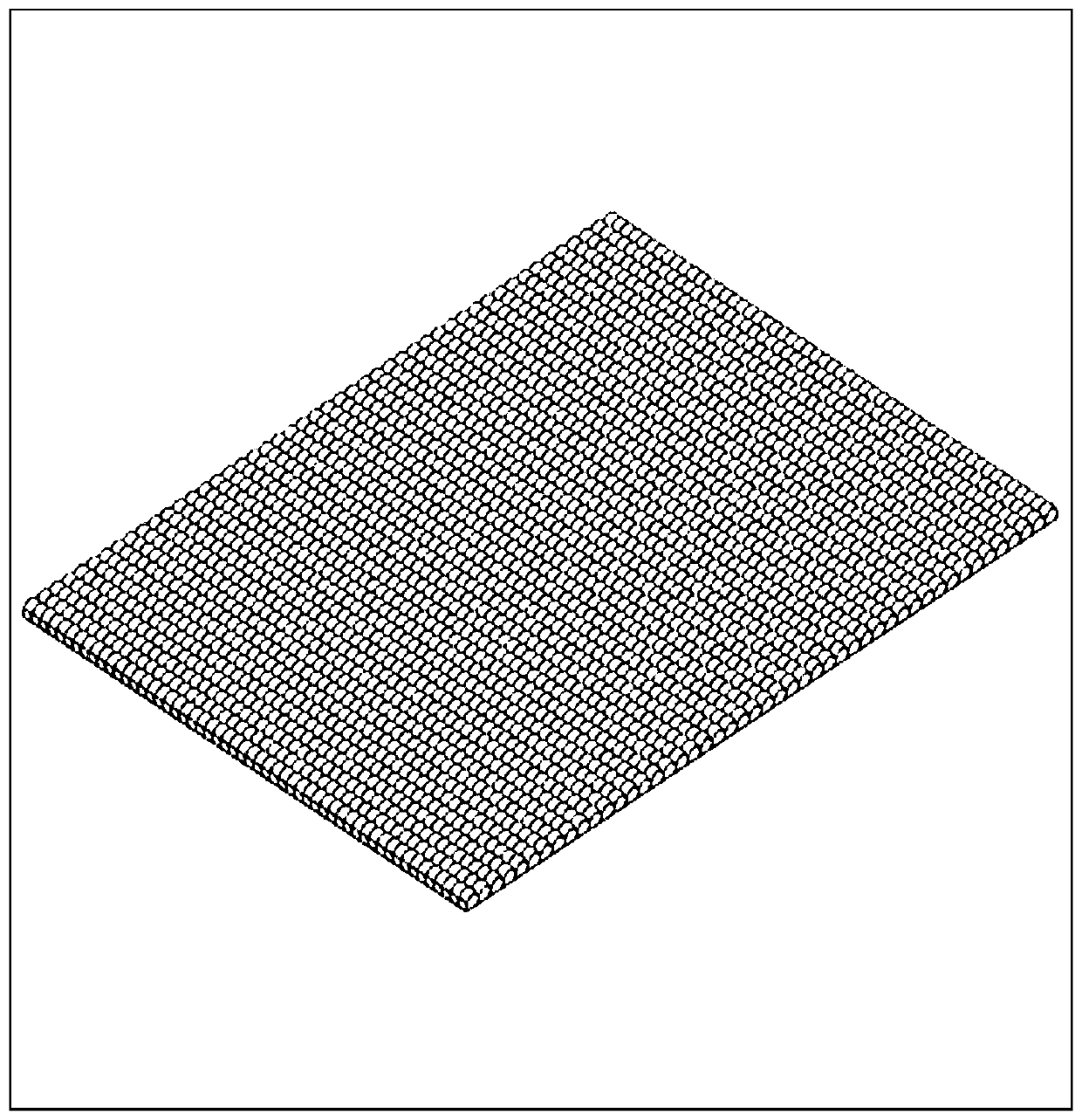

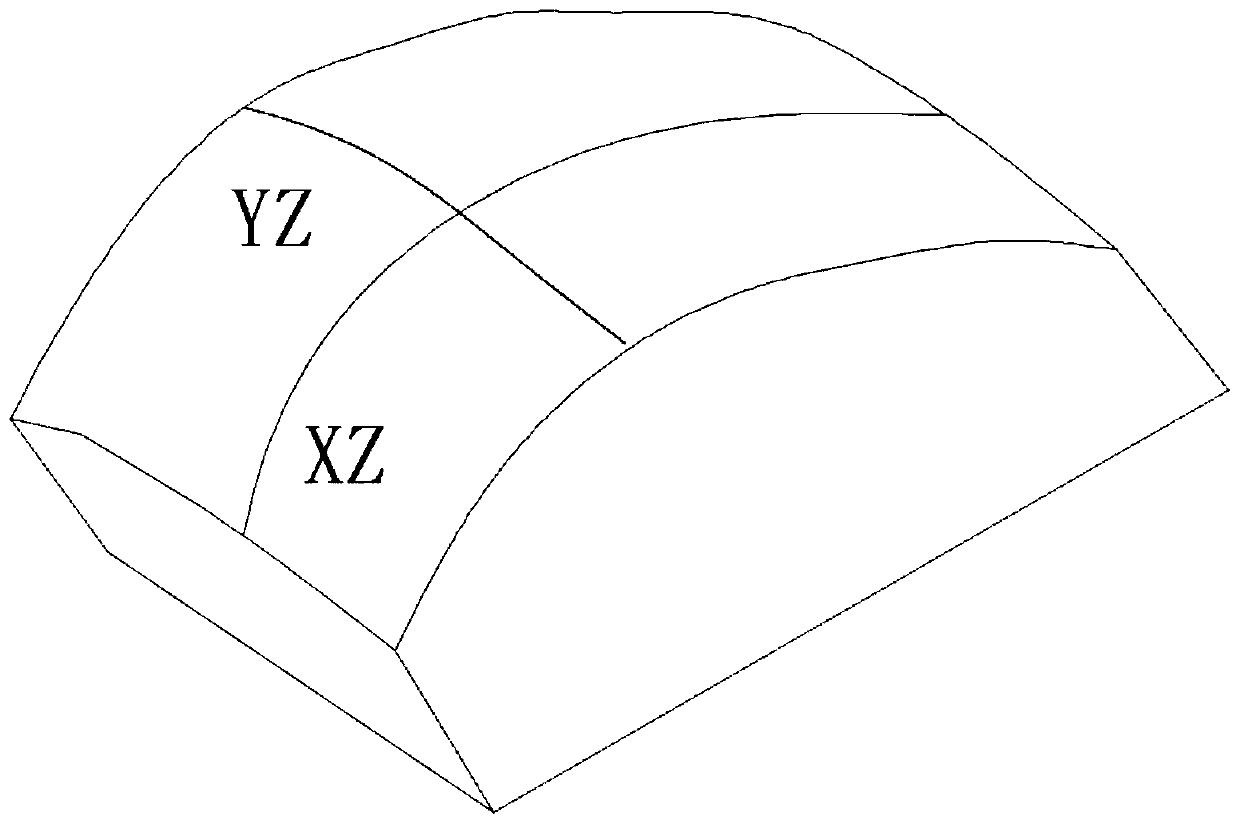

[0039] Embodiment: In the field of 3D recognition of mobile terminals such as mobile phones, rectangular spot lighting is often required. At this time, rectangular micro-lenses can be used for arrangement, such as figure 1 As shown, as an example, the size of each unit here can be 15*22.5 microns, and the shape of each unit microlens refers to the attached figure 2 ,Will figure 2 The unit is repeated to form an attached figure 1 The array element, the microlens of each unit can use the bionic surface to design an effective surface, and the reverse surface of the effective surface can be an ordinary plane or other shape surface, refer to Figure 5 with Image 6 Try to give a special case of surface shape, image 3 In this special case, a vcsel light source is used to illuminate the spot shape, and it can be seen that the effect of a rectangular spot can be better achieved. Figure 4 yes image 3 Intensity distribution curves in two directions of the light spot, the advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com