Manufacturing method of reactor internals middle ring

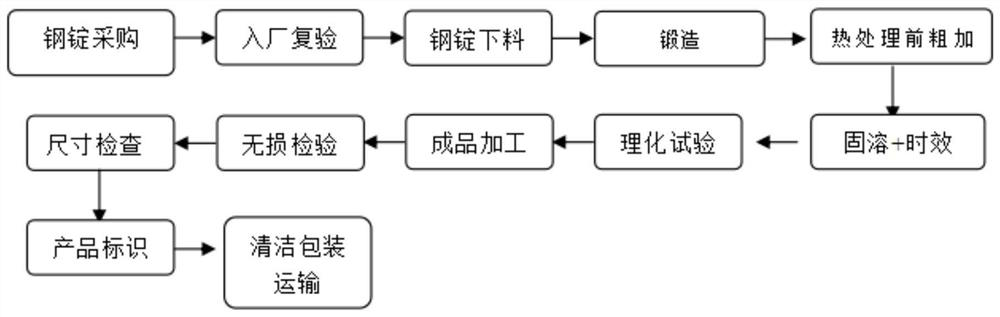

A manufacturing method and technology of internal components, applied in the field of forging in mechanical manufacturing, can solve problems such as large deformation resistance, narrow thermal deformation window, surface or internal defects, etc., achieve compression forging allowance, good comprehensive performance, and shorten processing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

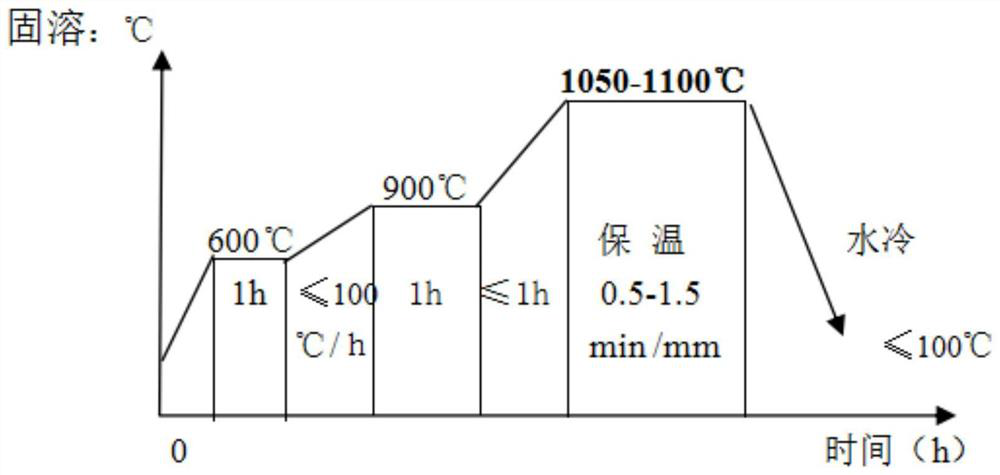

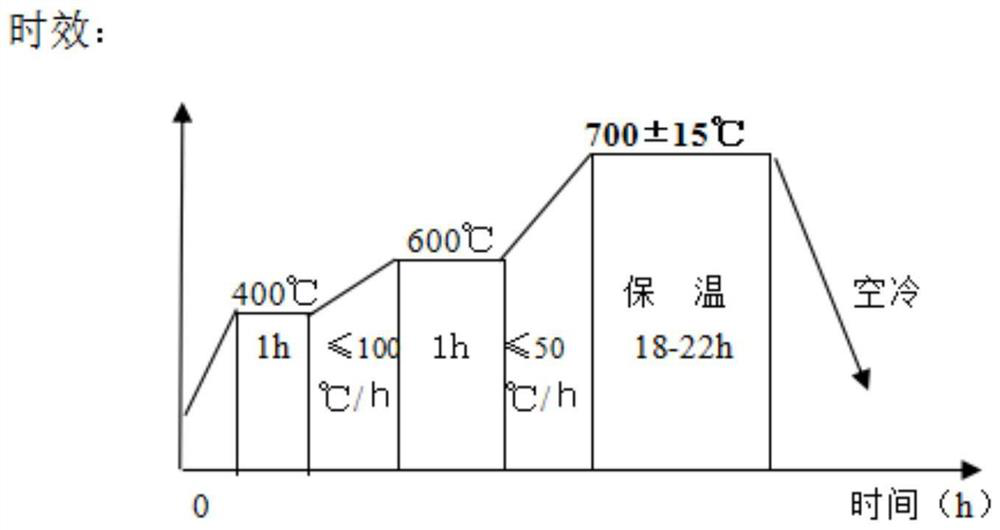

Method used

Image

Examples

Embodiment 1

[0042] Example 1: A manufacturing method for rings in heap internal components

[0043] Step S1: Raw material selection

[0044] The ingot adopts the EF+ESR process (electric furnace + electroslag remelting) to ensure the purity of the raw materials. Increase the internal control requirements for chemical components, and the internal control components are shown in the following table:

[0045] Reduce the C content, increase the Cr content, and improve the corrosion resistance of the material;

[0046] Increase the content of Ti, Al, Nb elements, improve the γ phase to generate elements, improve the strength of the material.

[0047]

[0048] Step S2: Forging

[0049] (1) The 1st-3rd fire: the steel ingot is about 2100kg, the forging temperature range is 1100 °C-950 °C, the steel ingot is tapped lightly, the casting stress of the steel ingot is released, and the octagonal cylindrical blank with an chamfering angle to about 500mm is returned to the furnace;

[0050] (2) The 4th f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com