Hub shaping mold

A wheel hub and mold technology, applied in the field of wheel hub shaping molds, can solve problems such as high cost, large heat treatment deformation, and increased material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

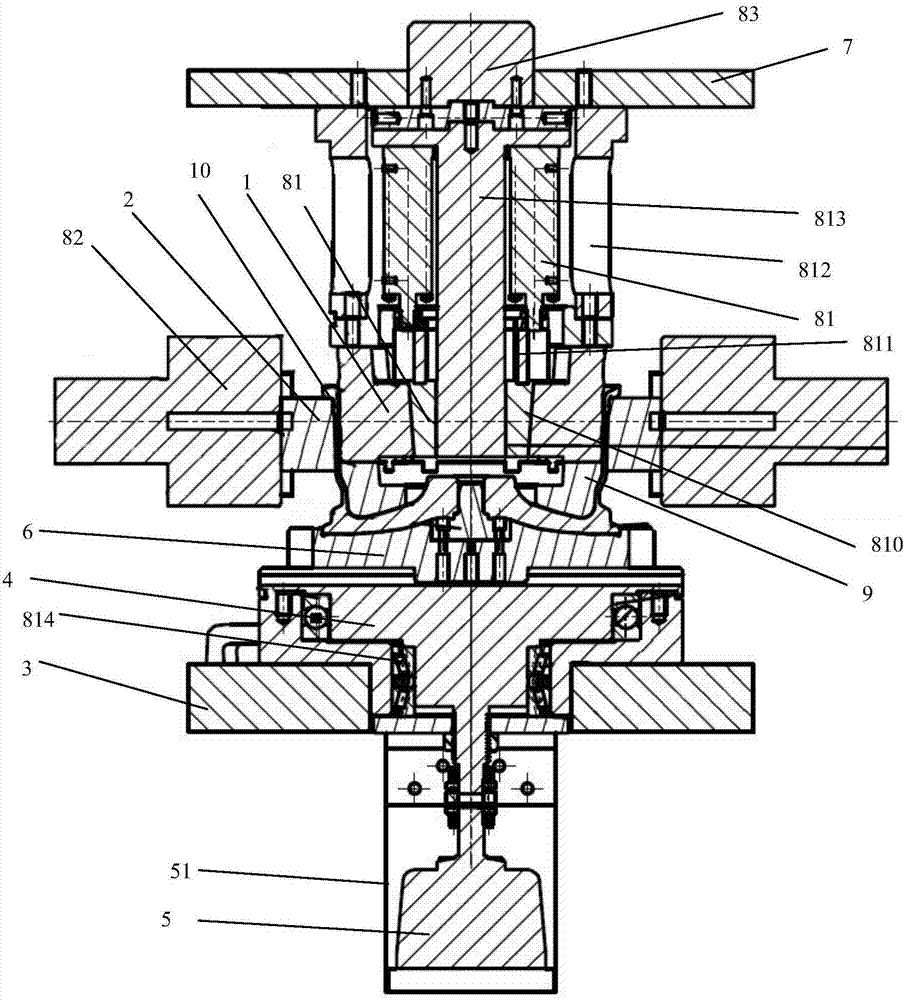

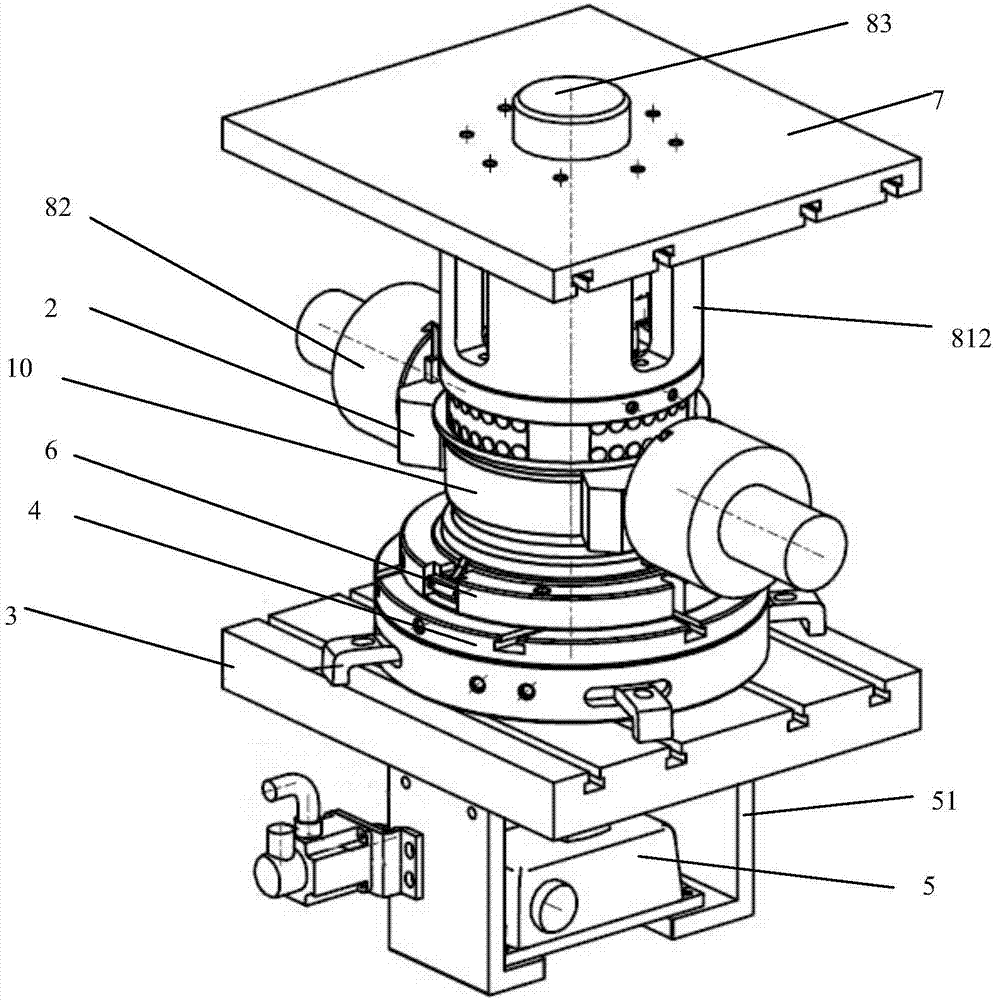

[0037] figure 1 is a sectional view of the wheel hub shaping die of the present invention, figure 2 It is a perspective view of the wheel hub shaping mold of the present invention, please refer to figure 1 , figure 2 As shown in the figure, a hub shaping mold of a preferred embodiment is shown, including: a lower worktable 3 , on which a rotary disk 4 is arranged, and the rotary disk 4 is driven by a motor 5 .

[0038] In addition, as a preferred embodiment, the hub shaping mold also includes: a lower mold core 6, the lower mold core 6 is fixed on the rotating disk 4, the upper surface of the lower mold core 6 matches the lower surface of the standard wheel hub, and the lower mold core 6 is fixed on the rotating disk 4. Claws are provided on the mold core 6, and the lower mold core 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com