A method of detecting the service lifetime of a filter screen of a vehicle-loaded purifier

A detection method and purifier technology, which are used in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of inaccurate automatic detection of filter life, loss of purification effect, and inability to effectively evaluate filter status.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

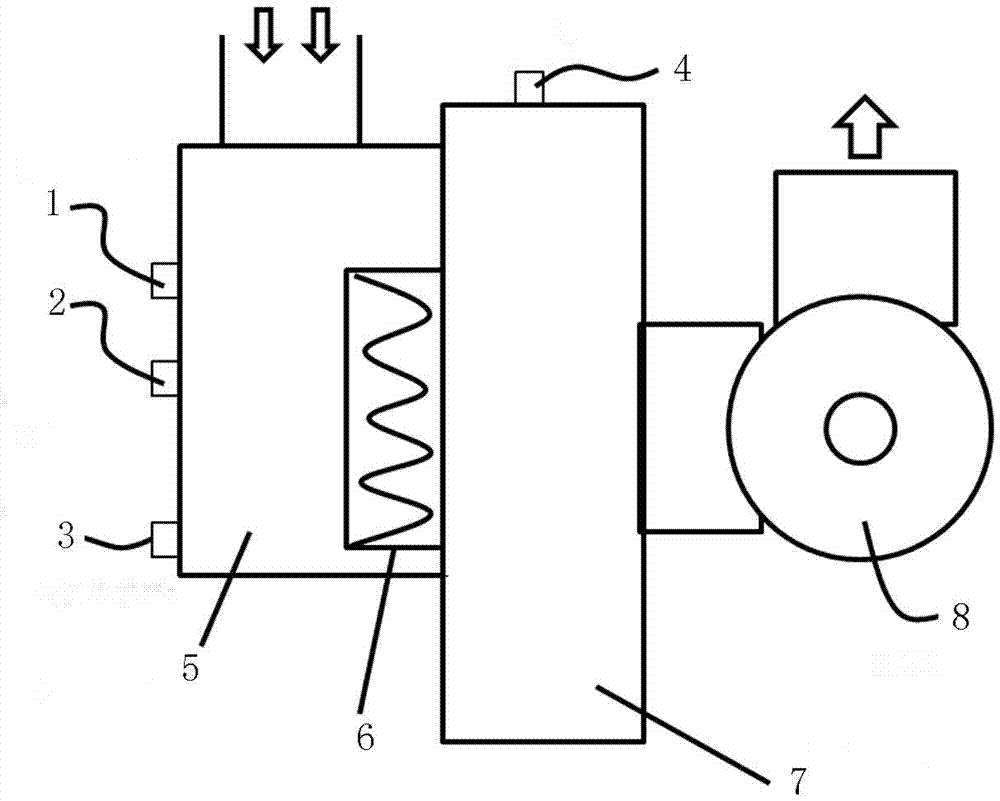

[0032] Such as figure 1 As shown, a purifier used in a method for detecting the life of a filter screen of a vehicle-mounted purifier includes an air inlet chamber, a filter screen, an interlayer and a fan connected in sequence, and a dust sensor 1 and an illumination sensor 2 are sequentially arranged in the air inlet chamber 5 of the purifier and the first air pressure sensor, and the second air pressure sensor is arranged in the interlayer. At the same time, install an external VOC concentration sensor anywhere in the car, and install a built-in VOC concentration sensor (not shown in the figure) in the interlayer.

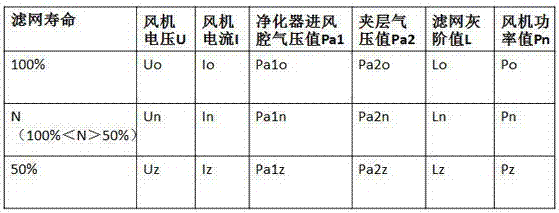

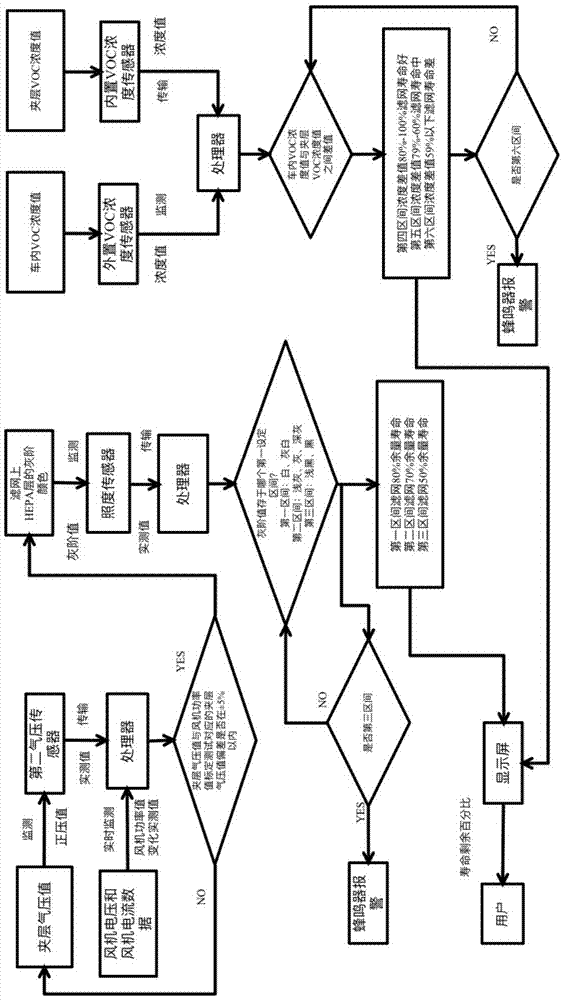

[0033] Such as figure 2 As shown, the method for detecting the life of the filter screen of the vehicle-mounted purifier disclosed in this embodiment includes the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com